Anticorrosive and insulating power equipment and manufacturing method thereof

A technology of electric equipment and anti-corrosion layer, applied in the direction of rubber insulators, organic insulators, winding insulation materials, etc., can solve the problems of poor anti-corrosion effect, poor water resistance, poor salt spray resistance, etc., and achieve low cost, good anti-corrosion, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

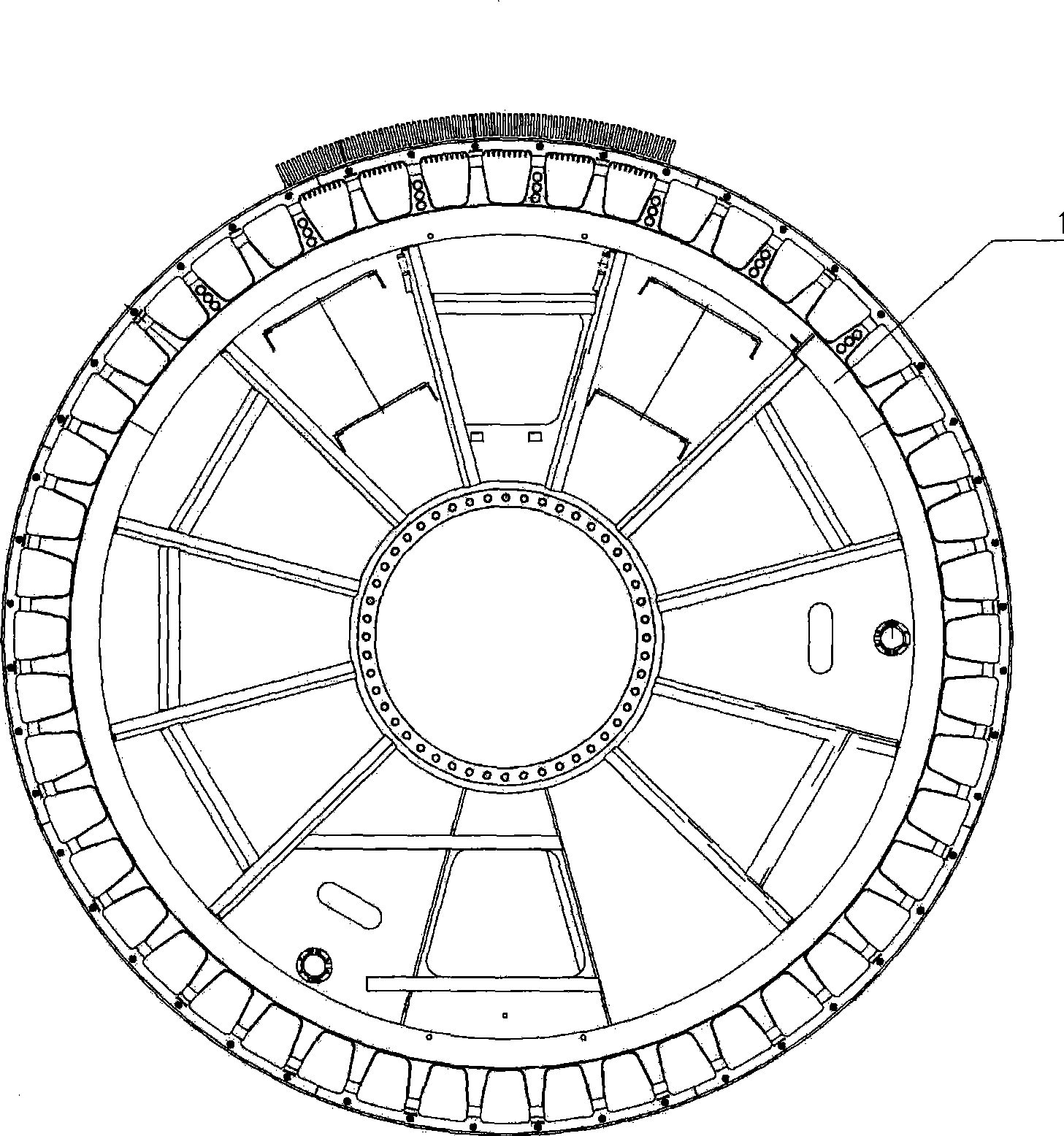

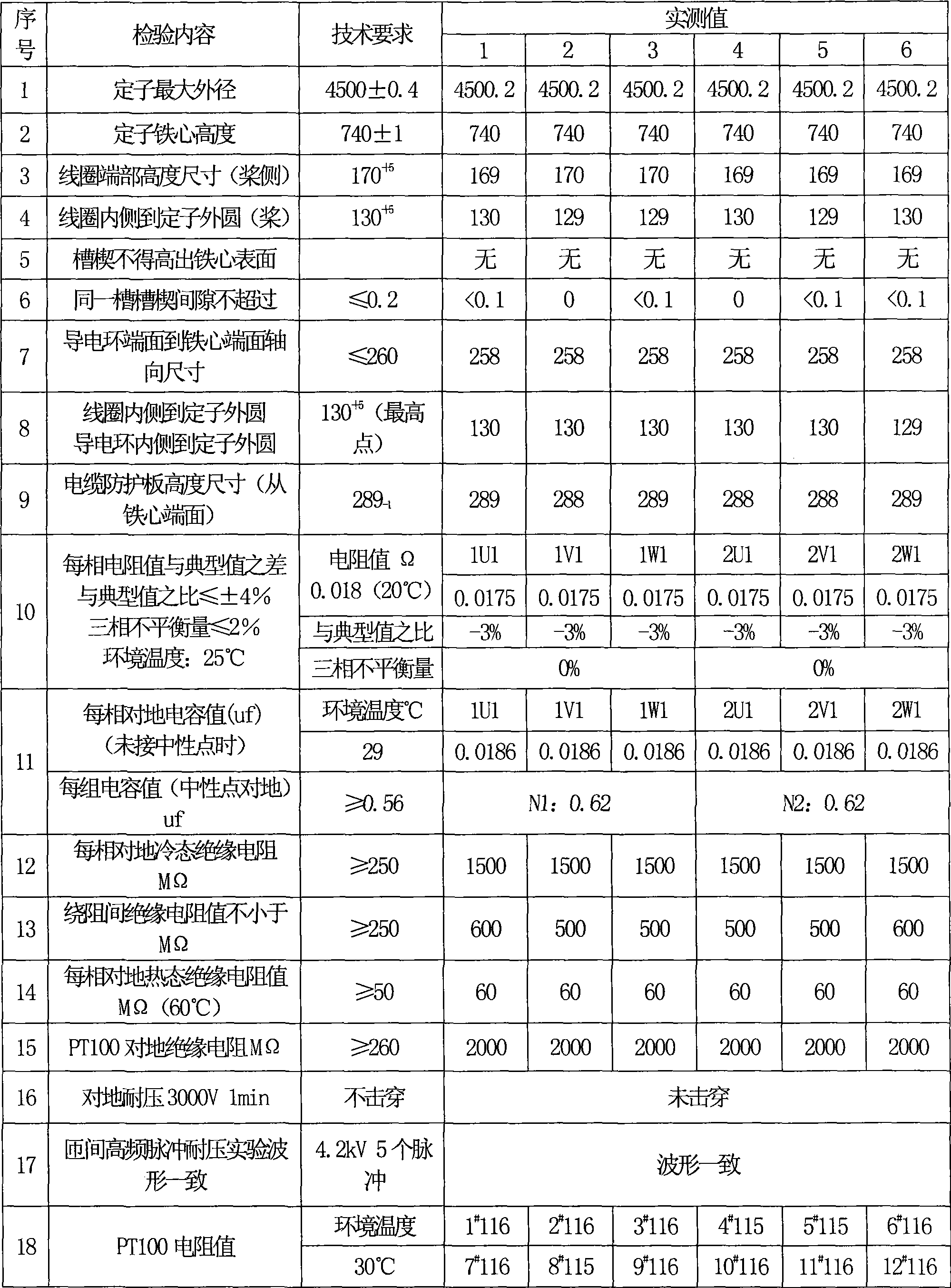

[0036] Embodiment 1, making the stator of an insulated and anti-corrosion generator

[0037] 1. Production of insulation and anti-corrosion generator stator

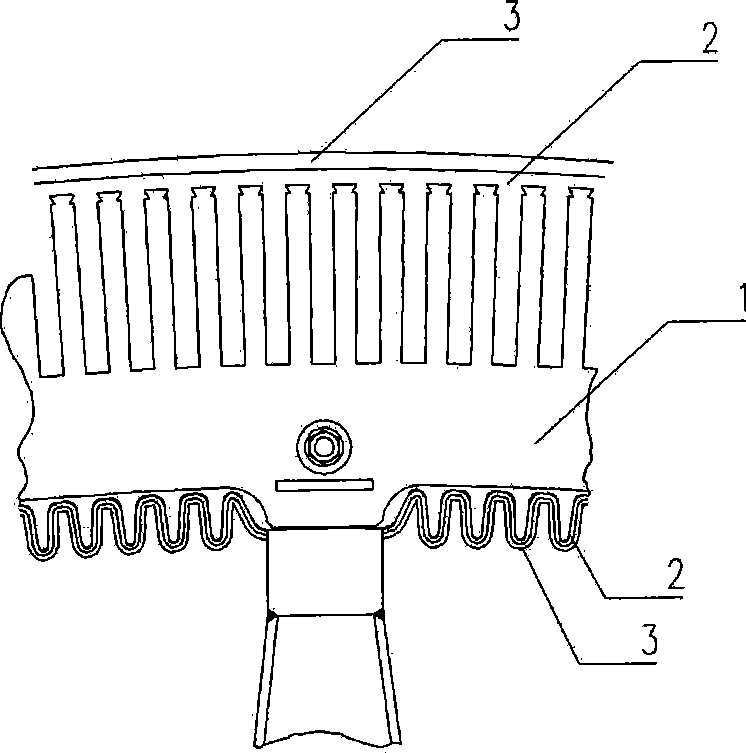

[0038] 1. Unsaturated polyimide solvent-free impregnated resin layer 2 is coated on the outside of the generator stator body 1

[0039] ① Impregnate the generator stator body 1 with unsaturated polyimide solvent-free impregnating resin.

[0040] ② Blow the stator of the generator clean and put it into the drying room to remove the moisture and low-molecular volatile components in the winding. The drying conditions are: 120°C, 2h.

[0041] The thickness of the unsaturated polyimide solvent-free impregnated resin layer 2 coated on the surface of the generator stator body 1 is 0.06mm.

[0042] 2. The unsaturated polyimide solvent-free impregnated resin layer 2 is covered with a fluorosilicone rubber layer 3

[0043] ① Place the generator stator obtained in step 1 on the support bracket, with the end of the lead wire faci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com