II-type polymer cement waterproofing coating modified by nano materials and preparation method thereof

A technology of nano-materials and waterproof coatings, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem of coating film strength, decreased adhesion, easy sagging of waterproof coatings, and weakened waterproof function and other problems, to achieve the effect of improved bond strength of wet interface, low cost, and improved water impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

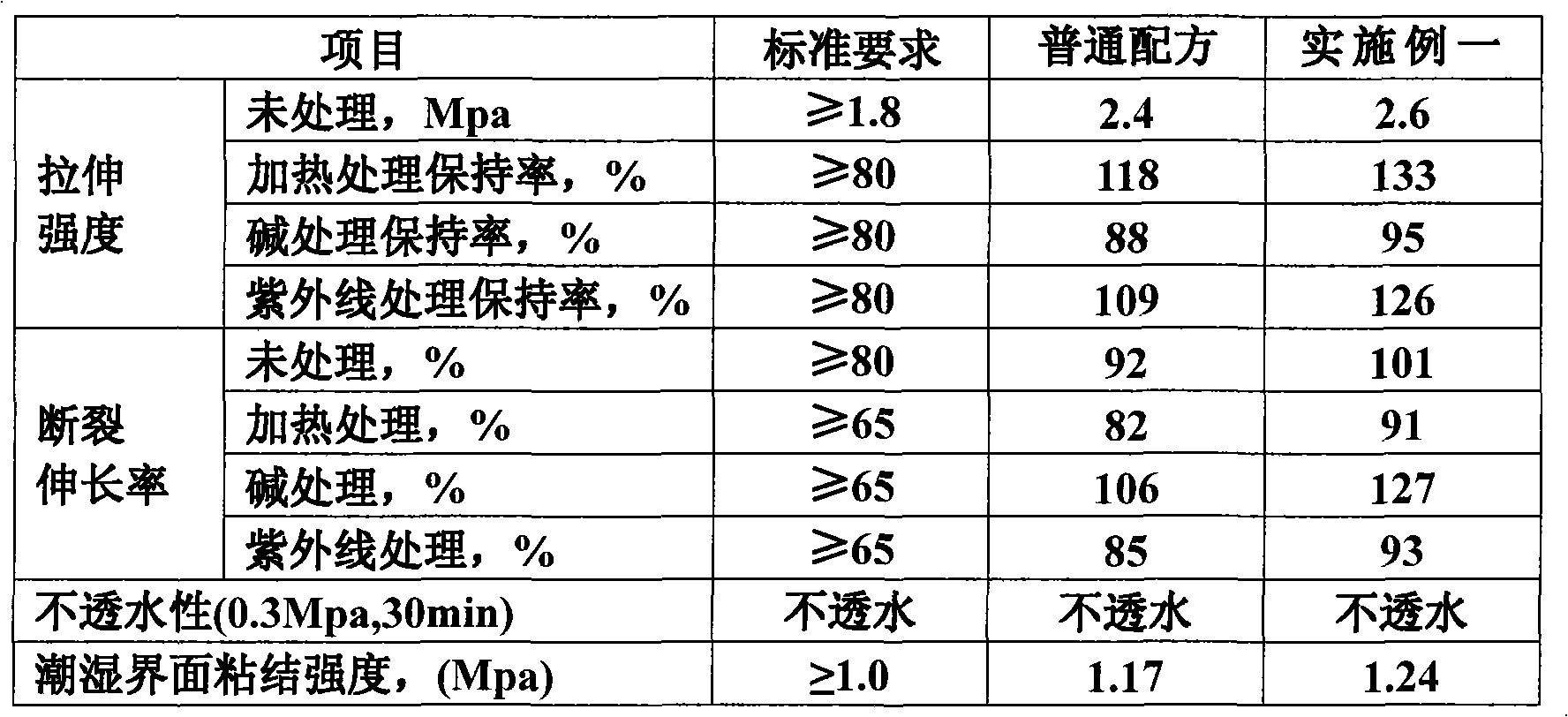

[0034] A nano-material modified type II polymer cement waterproof coating, which is composed of a liquid material component and a powder material component. The liquid material component and the powder material component are shown in the following table. Cement waterproof coatings (that is, without adding nanomaterials) were compared; the mixing ratio of the liquid material component and the powder material component was 10:14 by weight;

[0035] Liquid component

common formula

Embodiment one

Acrylic Emulsion

85

85

Phthalate Plasticizers

0.5

0.5

Dispersant

0.2

0.2

0.2

0.2

preservatives

0.1

0.1

Nano silica solution

2

Nano alumina solution

0.3

water

14

11.7

Powder component

cement

60

60

heavy calcium

20

20

Quartz sand

13.5

13.5

...

Embodiment 2

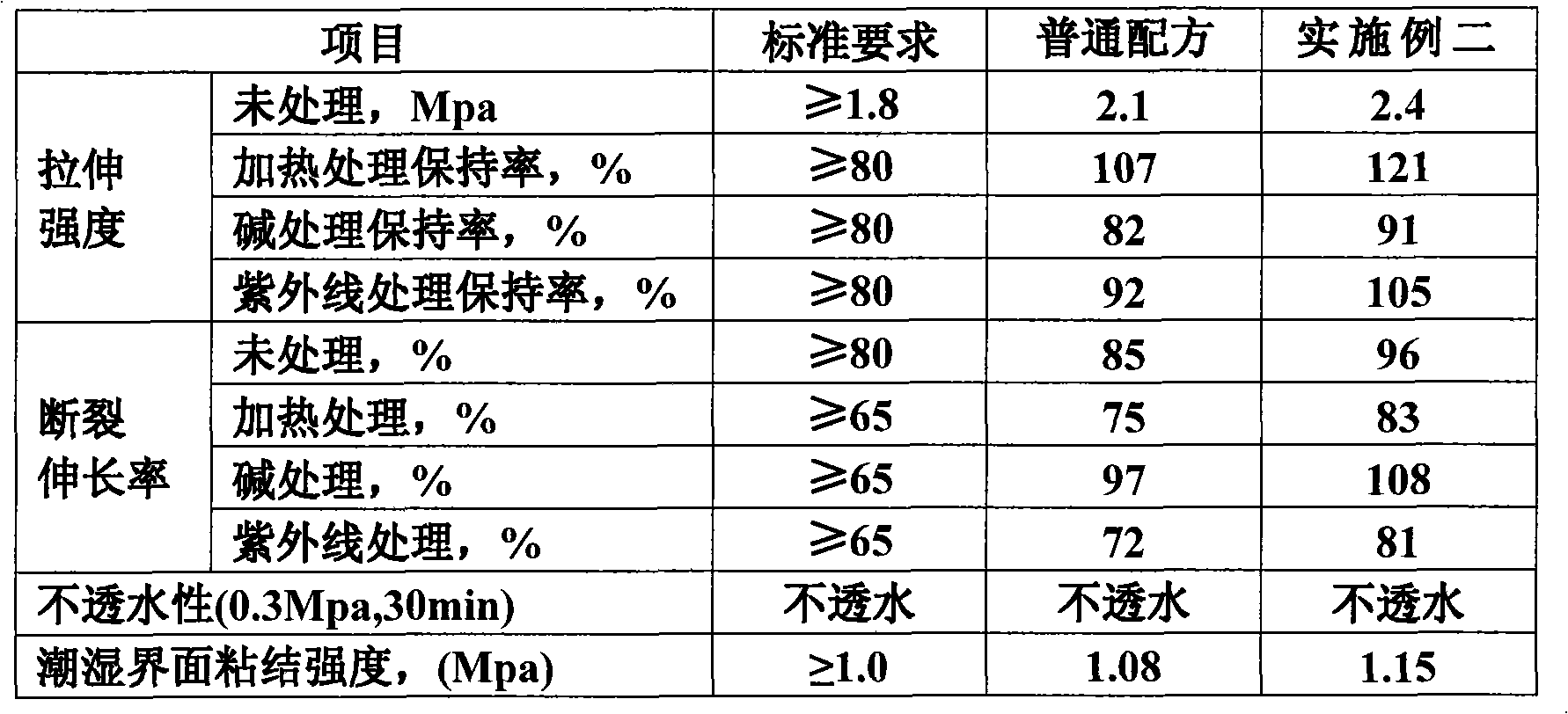

[0044] A nano-material modified type II polymer cement waterproof coating, which is composed of a liquid material component and a powder material component, and the liquid material component and the powder material component are shown in the following table Cement waterproof coatings (that is, without adding nanomaterials) were compared; the mixing ratio of the liquid material component and the powder material component was 10:17 by weight;

[0045] Liquid component

common formula

Embodiment two

Acrylic Emulsion

90

90

Phthalate Plasticizers

1

1

Dispersant

0.3

0.3

0.3

0.3

preservatives

0.2

0.2

Nano silica solution

1.5

Nano alumina solution

0.2

water

8.2

6.5

Powder component

cement

55

55

heavy calcium

29.2

29.2

Quartz sand

10

10

...

Embodiment 3

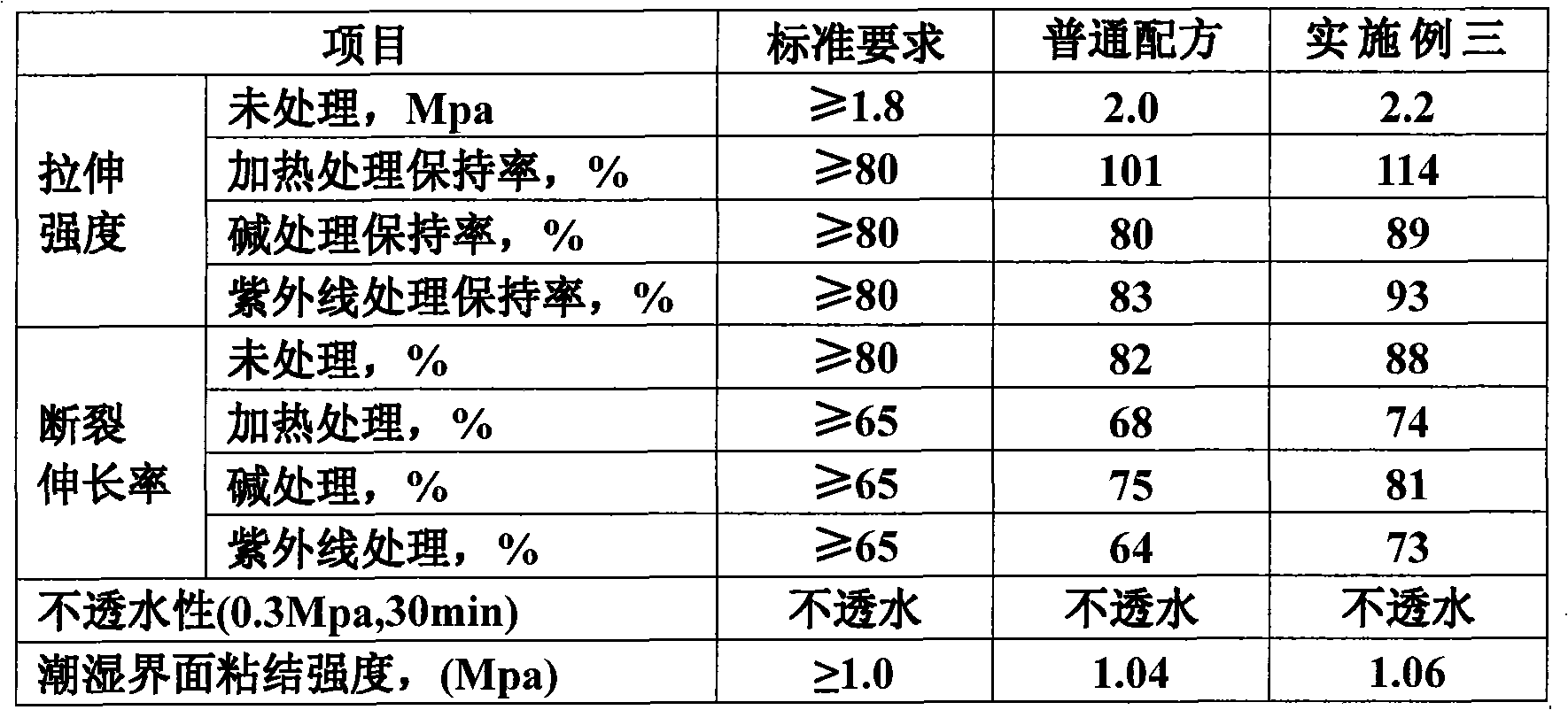

[0051]A nano-material modified type II polymer cement waterproof coating, which is composed of a liquid material component and a powder material component. The liquid material component and the powder material component are shown in the following table. Cement waterproof coatings (that is, without adding nanomaterials) were compared; the mixing ratio of the liquid material component and the powder material component was 10:20 by weight;

[0052] Liquid component

common formula

Embodiment three

Acrylic Emulsion

95

95

Phthalate Plasticizers

2

2

Dispersant

0.4

0.4

0.5

0.5

preservatives

0.3

0.3

Nano silica solution

1

Nano alumina solution

0.1

water

1.8

0.7

Powder component

cement

50

50

heavy calcium

30

30

Quartz sand

16

16

Talc po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com