Plasma processing apparatus

A plasma and processing device technology, applied in the field of plasma processing devices, can solve problems such as abnormal discharge, deterioration of uniformity, and damage to components or substrate S, and achieve the effects of suppressing arc light, suppressing abnormal discharge, and suppressing damage and loss

Active Publication Date: 2009-10-07

TOKYO ELECTRON LTD

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

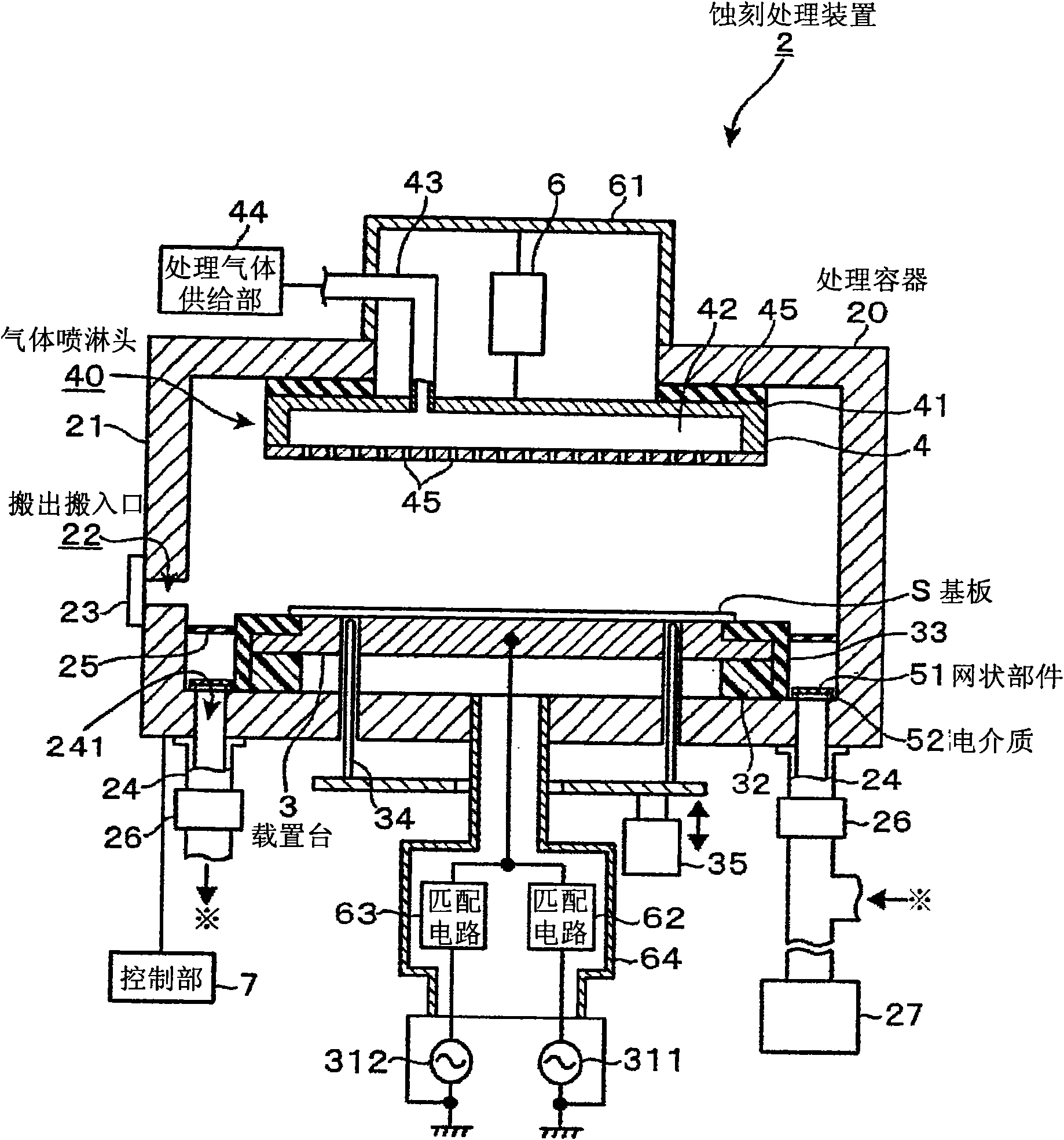

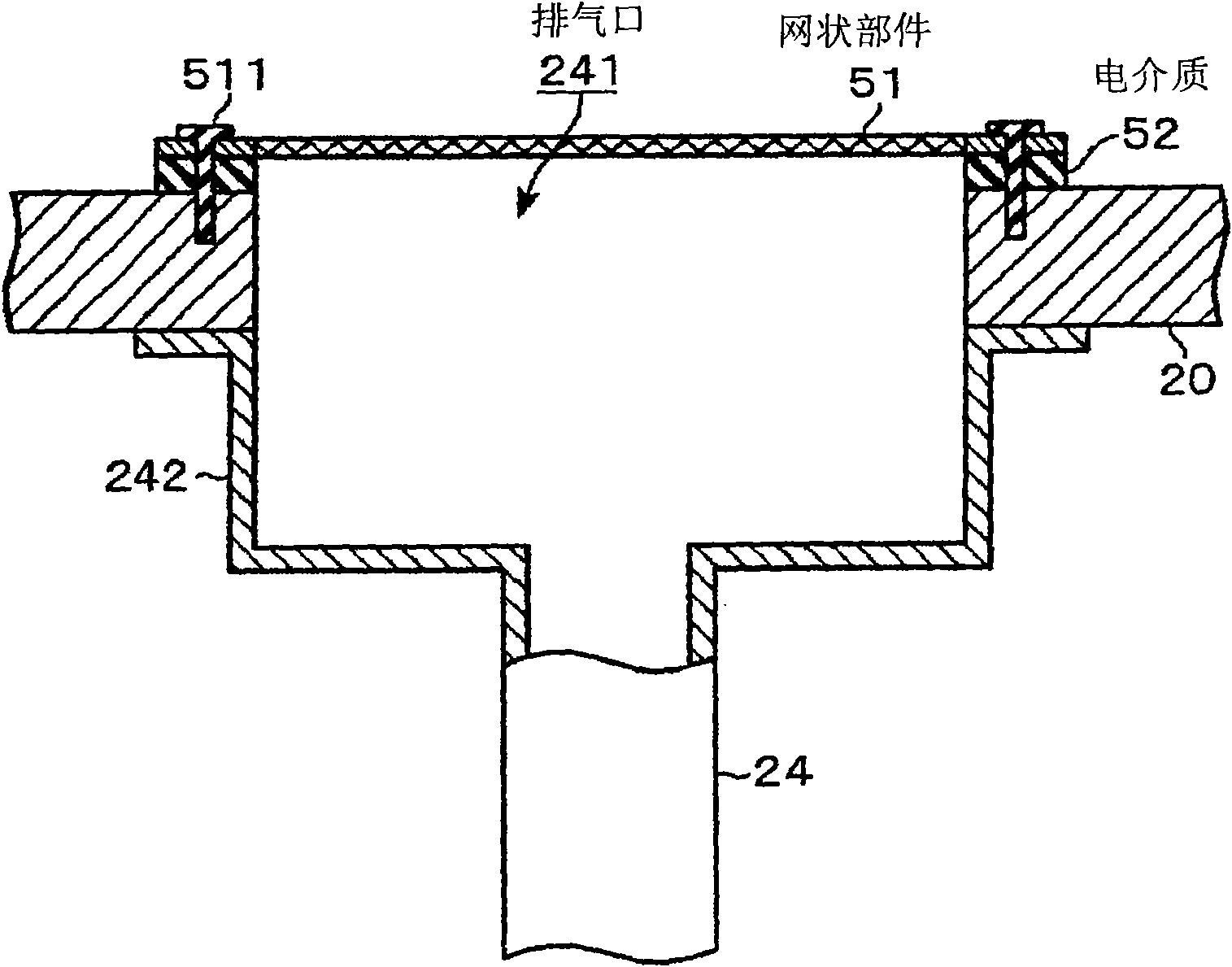

[0009] In addition, depending on the processing conditions such as gas flow rate and pressure, various pressure atmospheres are formed near the exhaust port of the exhaust passage 16 for the inflow gas in the processing container 10. Generally, the minimum voltage required to generate plasma between the electrodes is The pressure function of the space formed between the electrodes, therefore, combined with the above-mentioned main reasons, the lower electrode 11, which is the cathode electrode, and the mesh member 17 are prone to glow discharge.

[0010] As described above, if unnecessary capacitive coupling is formed between the lower electrode 11 and the mesh member 17 to locally generate a strong glow discharge, the space between the lower electrode 11 and the upper electrode 12, which is the original plasma generation space, will The plasma may become unstable. For example, it may induce arc-shaped abnormal discharge, that is, arc light, on the surface of the components or the substrate S in the processing container 10, so that the above-mentioned components or the substrate S are damaged or lost. In addition, due to the deflected plasma body, which may lead to poor in-plane uniformity of the processed substrate S

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0092] A dielectric 52 made of alumina is provided between the mesh member 51 b and the bottom wall surface of the processing container 20 .

Embodiment 2

[0101] A dielectric 52 is provided between the mesh member 51 b and the processing container 20 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Login to View More

Abstract

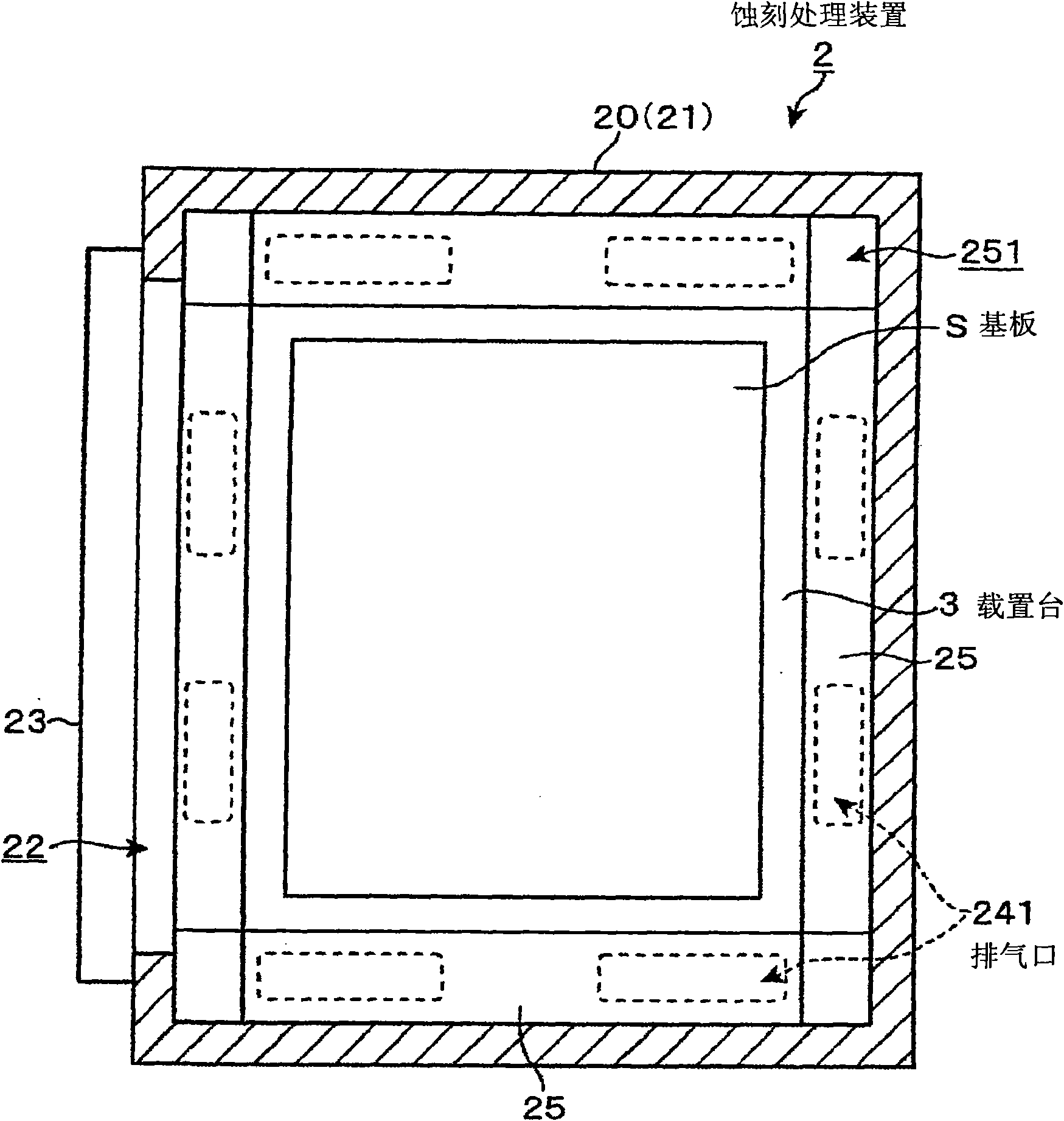

The present invention provides a plasma processing apparatus, capable of restraining an abnormal discharge from generating between a cathode electrode and a netted member for shrouding an exhaust outlet in a parallel flat-plate type plasma processing apparatus. The plasma processing apparatus (2) applies a high frequency electric force between an anode electrode (gas spray head (40) ) and a cathode electrode (carrying bench (3)) facing with each other in a processing container (20) to implement a plasma treatment to the processing gas and implement a plasma treatment to a processed object (S), wherein a conductive member (netted member 51) having an opening is arranged around the cathode electrode to shroud the exhaust outlet for discharging the processing gas, and an electrolyte (52) is arranged between the conductive member and a conductive wall of the processing container (20).

Description

[0001] technology area [0002] The present invention relates to a plasma processing apparatus that converts a processing gas into plasma by high-frequency power, and performs processing such as etching on an object to be processed by the plasma. Background technique [0003] In the manufacturing process of flat panels such as semiconductor equipment and liquid crystal display devices, in order to perform processing such as etching or film formation on semiconductor wafers or substrates to be processed called glass substrates, plasma etching equipment or plasma CVD is used. Plasma processing equipment such as membrane equipment. [0004] Figure 8 The shown plasma processing apparatus is a configuration example of a plasma etching apparatus for etching a thin film formed on a glass substrate for FPD (Flat Panel Display), for example. This plasma etching apparatus is configured as a parallel plate type plasma processing apparatus in which an upper electrode 12 is provided in a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01L21/00H01L21/3065H01L21/311H01L21/20H05H1/24

CPCH01J37/3244H01J37/32633H01J37/32807H01L21/3065H01L21/67069H05H1/46

Inventor 佐藤亮齐藤均

Owner TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com