Transient voltage suppresser diode and manufacturing method thereof

A technology of transient voltage suppression and manufacturing method, applied in the field of diodes, can solve the problem of high capacitance value of TVS diodes, and achieve the effects of large-scale production, simple process flow, and improved controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

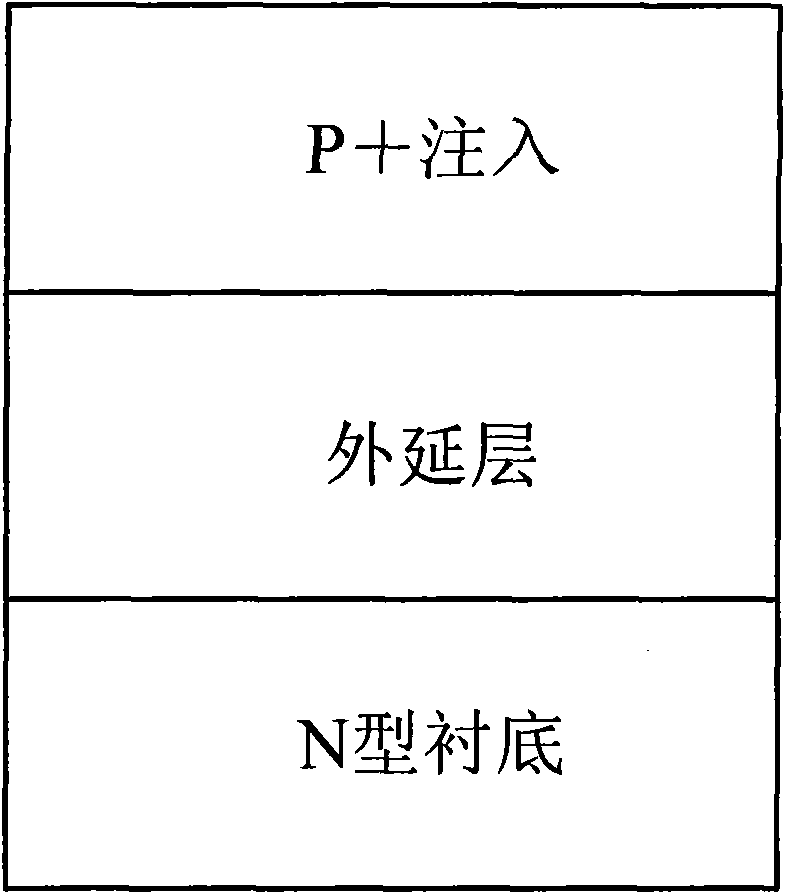

[0050] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

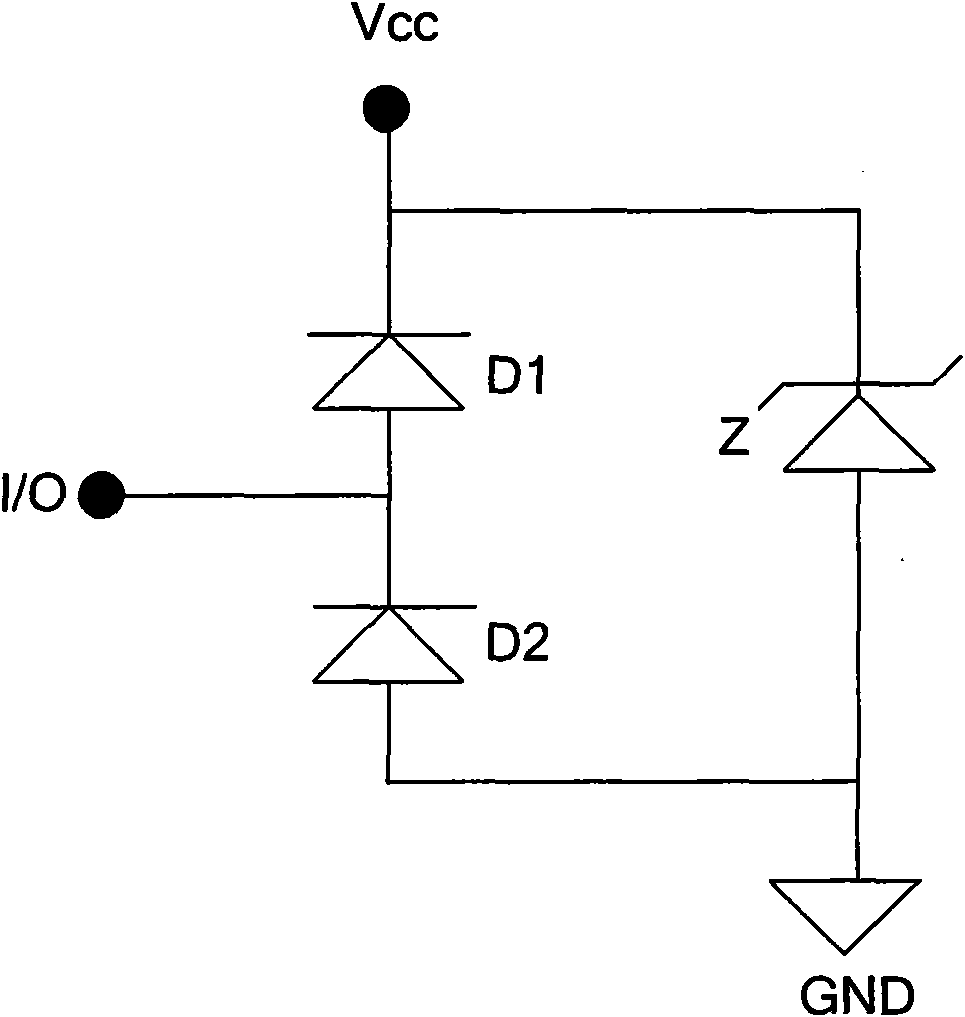

[0051] figure 2 It is the basic electronic circuit application diagram of the TVS diode of the present invention. like figure 2As shown, the ultra-low capacitance TVS diode of the present invention includes two steering diodes with small area and relatively high breakdown voltage---the first steering diode D1 and the second steering diode D2, one is reverse Zener diode Z with a breakdown voltage of 6V, the first steering diode D1, the second steering diode D2 and the Zener diode Z are connected in parallel, the first steering diode D1 and the second steering diode D2 are set There is an I / O interface, the P junction of the first steering diode D1 is connected to the N junction of the second steering diode D2, and a voltage signal line Vcc is provided between the first steering diode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com