Method for preparing dendritic cadmium sulfide

A cadmium sulfide and dendritic technology, applied in the field of preparation of inorganic material cadmium sulfide, can solve the problems of high cost, unfavorable large-scale production, low purity of target product, etc., and achieve the effects of low cost, realization of mass production and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

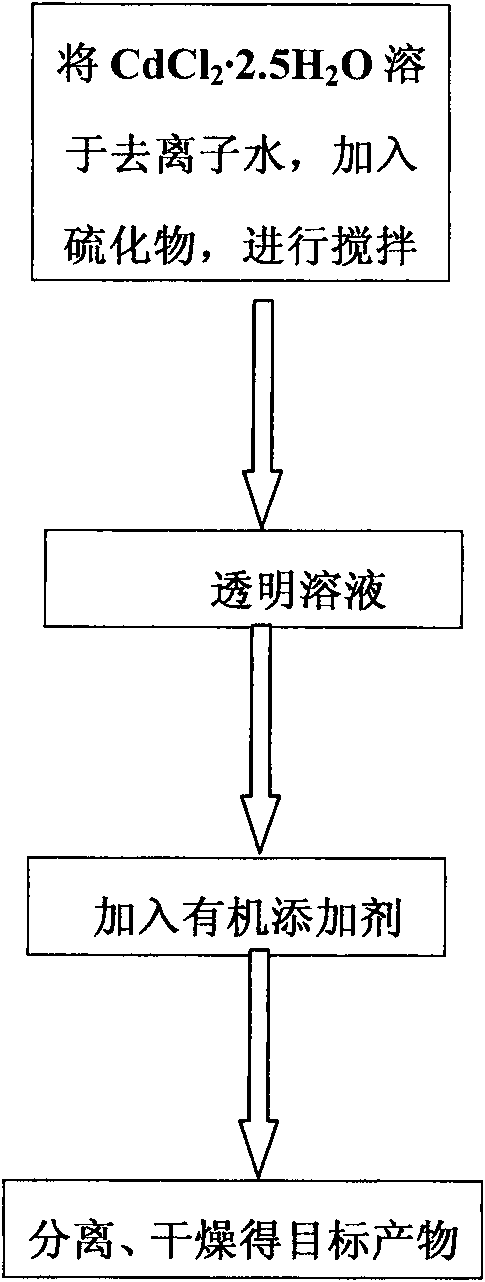

[0030] Such as figure 1 As shown, take 0.45g of CdCl 2 2.5H 2 O was dissolved in 80mL deionized water, and 0.46g of CS(NH 2 ) 2 Stir until a clear solution forms. Take 0.089g of L-alpha-alanine and add to the above solution, and stir at room temperature for 15min. Then add it to a 100mL hydrothermal kettle and seal it. Heating at 200°C for 12h, after the reaction, the product was isolated, washed to remove impurities, and dried at 80°C for 6h.

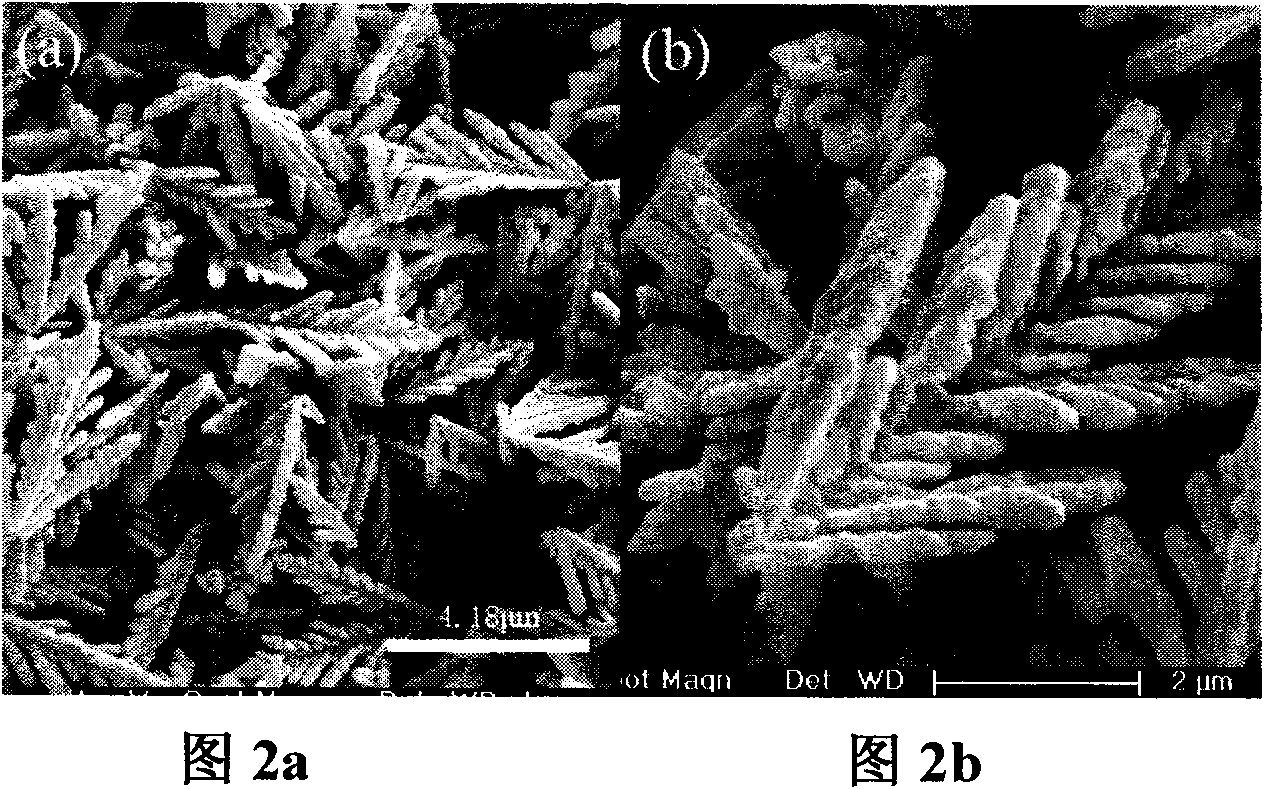

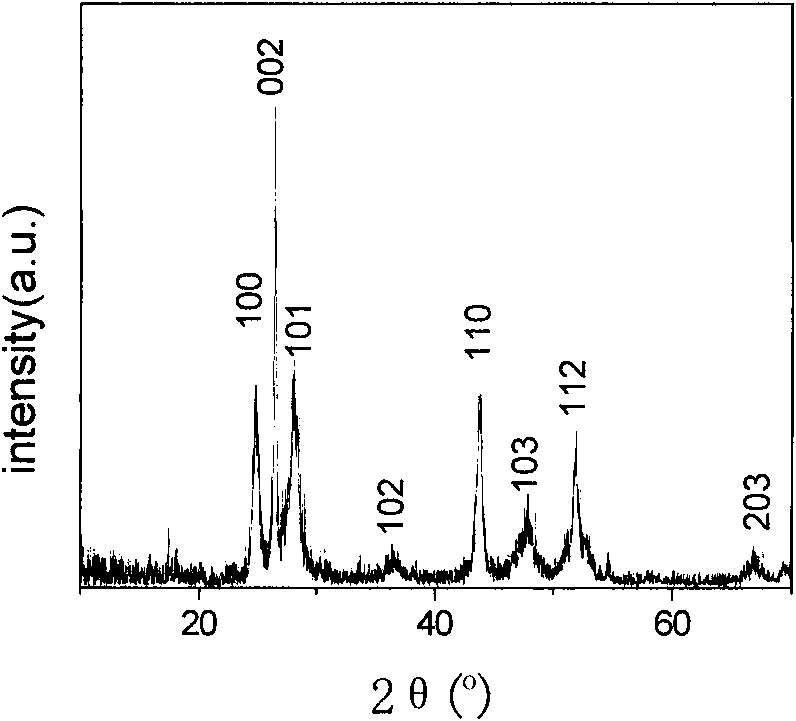

[0031] observed directly under a field emission scanning electron microscope. Figure 2a and Figure 2b , it can be seen from the figure that the overall shape of the product is dendritic, the purity is very high, and there is no other shape. The average length of the dendritic backbone is 4-6 μm, from Figure 2b You can see the neatly arranged branches, and the two rows of branches are almost perpendicular to each other. Each branch grows sequentially at a small angle to the main axis. The surface of the branches is relative...

Embodiment 2

[0034] Take 0.45g of CdCl 2 2.5H 2 O was dissolved in 80mL deionized water, and 0.46g of CS(NH 2 ) 2Stir until a clear solution forms. Take 0.089g of L-alpha-alanine and add to the above solution, and stir at room temperature for 15min. Then add it to a 100mL hydrothermal kettle and seal it. Heating at 180°C for 12h, after the reaction, the product was isolated, washed to remove impurities, and dried at 80°C for 6h. The morphology and structure of the product after drying are the same as in Example 1.

Embodiment 3

[0036] Take 0.45g of CdCl 2 2.5H 2 O was dissolved in 80mL deionized water, and 0.46g of CS(NH 2 ) 2 Stir until a clear solution forms. Take 0.089g of L-alpha-alanine and add to the above solution, and stir at room temperature for 15min. Then add it to a 100mL hydrothermal kettle and seal it. Heating at 200°C for 2h, after the reaction, the product was isolated, washed to remove impurities, and dried at 80°C for 6h. The product looks like Figure 4a , it can be seen from the figure that the reaction time has an important influence on the morphology of cadmium sulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com