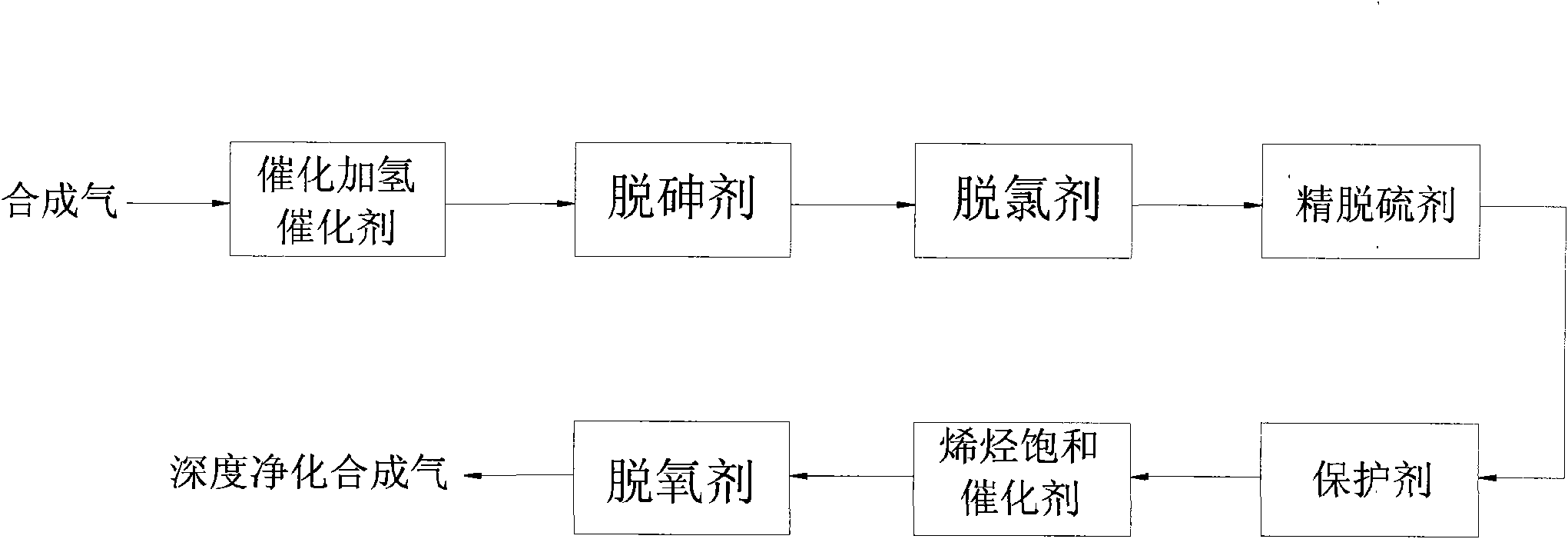

Deep combined purification process for synthetic gas

A purification process and deep purification technology, used in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve problems such as treatment, and achieve the effect of simplifying the purification process and improving the depth of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The synthetic gas from underground coal gasification has a gas volume of 100Nm after crude desulfurization and decarbonization 3 / h, the gas temperature is normal temperature, the pressure is normal pressure, the sulfur content is about 20ppm, the chlorine is about 20ppm, the arsenic is about 10ppm, the olefin is about 0.5%wt, and the oxygen is about 0.3%wt. At the beginning of the design of the device, after the synthesis gas undergoes fine desulfurization and deoxidation, the sulfur is removed to about 0.1ppm, and the oxygen is about 1ppm, and then enters the methane synthesis section. Three months after the operation of the unit, the methanation catalyst bed showed obvious deactivation performance.

[0041] By improving the device, a deep combined purification device for synthesis gas has been added: the synthesis gas passes through the catalytic hydrogenation tower of the present invention (XNJ type catalytic hydrogenation catalyst is installed in the tower), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com