New iron-making and steel-making process by one-step method and equipment thereof

A new process and step-by-step technology, applied in the field of one-step iron-smelting and steel-making new technology and its equipment, can solve the problems of inability to discharge slag alone, high one-time investment, complicated operation procedures, etc., and achieve simple structure and low equipment investment. , Reasonable effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

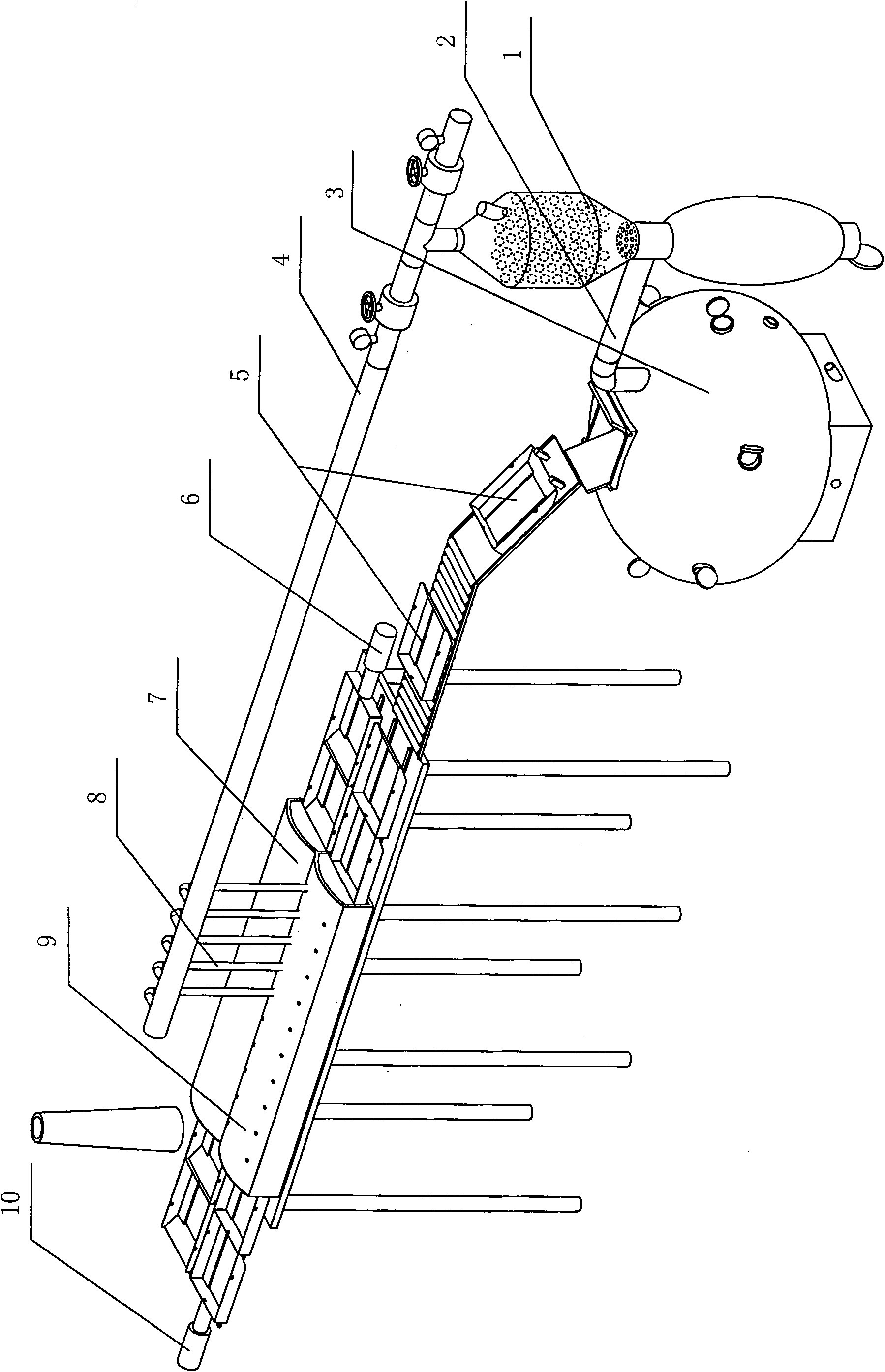

[0015] Example 1: The process of the present invention includes iron pellet drying and direct reduction, such as figure 1 As shown, the drying and direct reduction of the iron pellets are carried out in the drying and direct reduction furnace disclosed in the applicant’s patent application number 200810140107.0, titled "A new process for ironmaking without blast furnace". The pellet carrying trolley 5 is pushed by the top cylinder 6 into the drying furnace 7 for iron pellet drying, and then pushed by the top cylinder 10 into the direct reduction furnace 9 for direct reduction, and then pushed out from the direct reduction furnace 9, The directly reduced hot iron pellets are put into the dual-purpose furnace 3 for ironmaking and steelmaking. At the same time, it is equipped with 60-100kg of anthracite lump and slag material for ton of iron. Perform high-pressure oxygen blowing and bottom blowing and stirring in the same direction on the surface to rotate the liquid surface to impl...

Embodiment 2

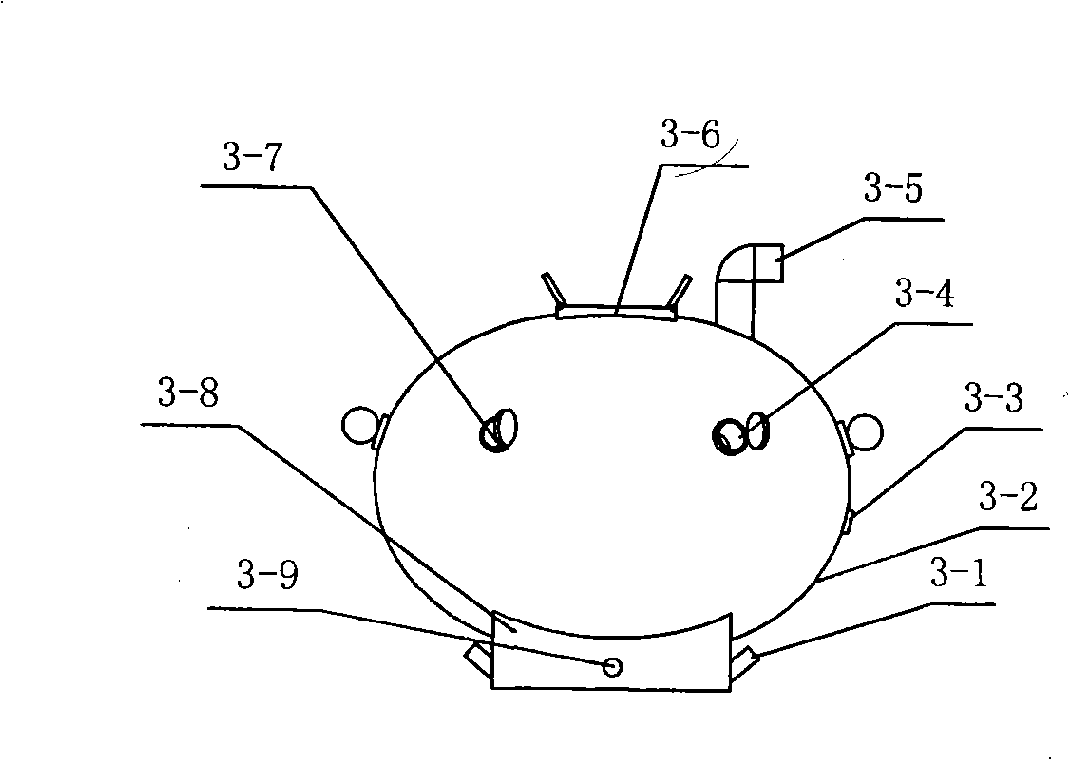

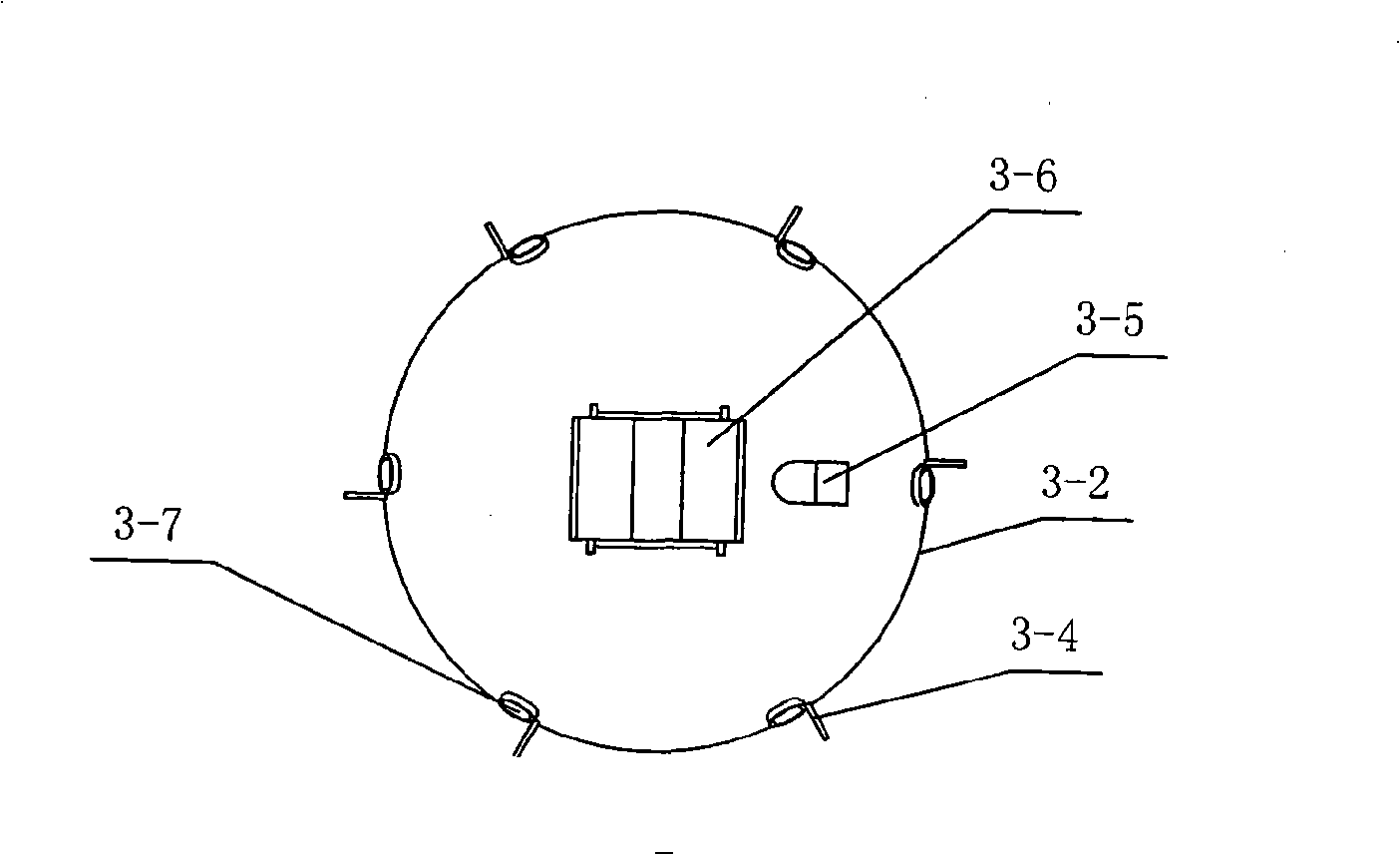

[0016] Example 2: The iron-making and steel-making dual-purpose furnaces 3 such as figure 2 , image 3 , Figure 4 As shown in the figure, 3-2 is the furnace body. Its main viewing axis is a horizontal ellipse, and it is circular when viewed from above. The top is equipped with a feeding port and a normally closed double flap valve 3-6; furnace body 3- The bottom of 2 is equipped with an iron storage tank 3-8, the upper part of the iron storage tank 3-8 is equipped with a tap hole 3-9; the lower part of the furnace body 3-2 is equipped with a slag removal port 3-3, and the middle part is equipped with a There are several oblique oxygen blowing ports that make oxygen swirl in the furnace. The oxygen blowing ports are divided into medium and low pressure oxygen blowing ports 3-4 and high-pressure oxygen blowing ports 3-7. In the medium and low pressure oxygen blowing iron smelting and high pressure oxygen blowing steel smelting, the upper part of the furnace body 3-2 is provided wi...

Embodiment 3

[0017] Example 3: The carbon dioxide reduction furnace 1 of the process of the present invention Figure 5 As shown, it is composed of connected upper warehouse 1-3 and lower warehouse 1-2. The upper warehouse 1-3 is used to contain coal for carbon dioxide reduction and limestone for desulfurization. The coal port 1-4 is added, the bottom of the upper warehouse 1-3 is equipped with a grate 1-6, and the top is equipped with an exhaust port 1-5; the bottom of the lower warehouse 1-2 is equipped with a dust outlet 1-1, upper and lower The connecting part of the bin is provided with air inlets 1-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com