Hydrogen absorbing and releasing alloy material and application thereof

An alloy material, hydrogen absorption and desorption technology, applied in the field of high temperature anti-phase separation vacuum interlayer hydrogen absorption and desorption alloy material, automobile exhaust cold start pollution control or diesel vehicle exhaust particle pollution control, can solve reversible deterioration, pollution control system, Complicated problems, to achieve the effect of improving high temperature stability, simplifying pollution control system, and good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Press Ti 0.7 Nb 0.3 Carry out batching, adopt TiNb alloy to obtain TiNb alloy by electric arc melting method, then carry out rapid phase-separation aging test (corresponding to at least 10000 high-temperature hydrogen absorption and desorption cycles) according to the method in Comparative Example 1, the temperature is 600 ℃, the hydrogen pressure is 80 atmospheres, The aging time is 20 hours. It was found that the alloy was still in the original block shape, without phase separation, and the hydrogen absorption and desorption performance lost 23%.

Embodiment 2

[0027] Press Ti 0.8 Mo 0.2 Carry out batching, adopt magnetic suspension smelting method to obtain TiMo alloy, then carry out rapid phase-separation aging (same as embodiment 1), find that the alloy is still in the original block shape, without phase separation, and the hydrogen absorption and desorption performance loses 16%.

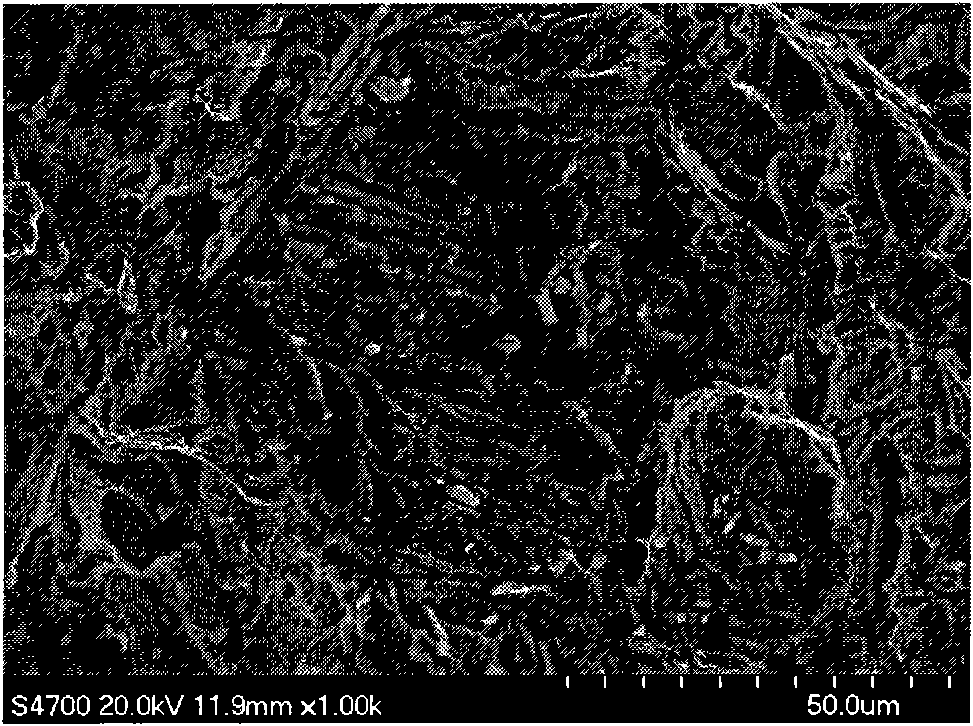

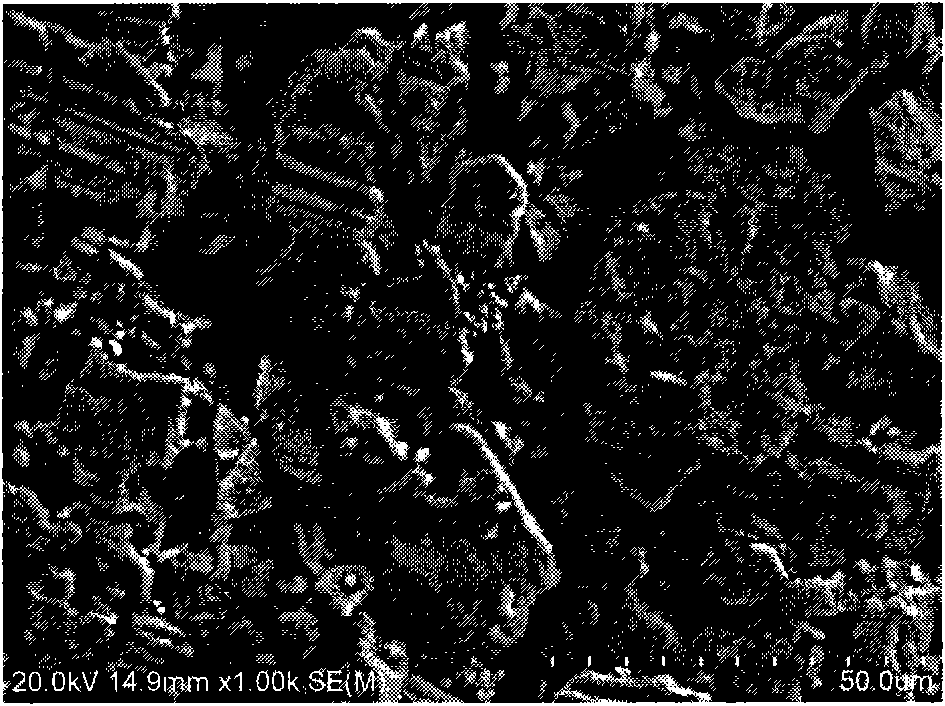

[0028] The TiMo alloy surface appearance that embodiment 2 obtains is as figure 1 shown.

Embodiment 3

[0030] Press Zr 0.5 La 0.2 Fe 0.3Carry out batching, adopt arc melting method to obtain ZrLaFe alloy, carry out rapid phase-separation aging (same as embodiment 1) then, find that the alloy is still the original bulk, without phase-separation, hydrogen absorption and desorption performance loss of 21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com