Preparation method of rare earth oxide reinforced titanium-based composite material

A technology of titanium-based composite materials and rare earth oxides, applied in additive processing, additive manufacturing, metal processing equipment, etc., can solve the problems of poor oxidation resistance of titanium-based alloy materials, and achieve good fluidity, uniform particle size, and sphericity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

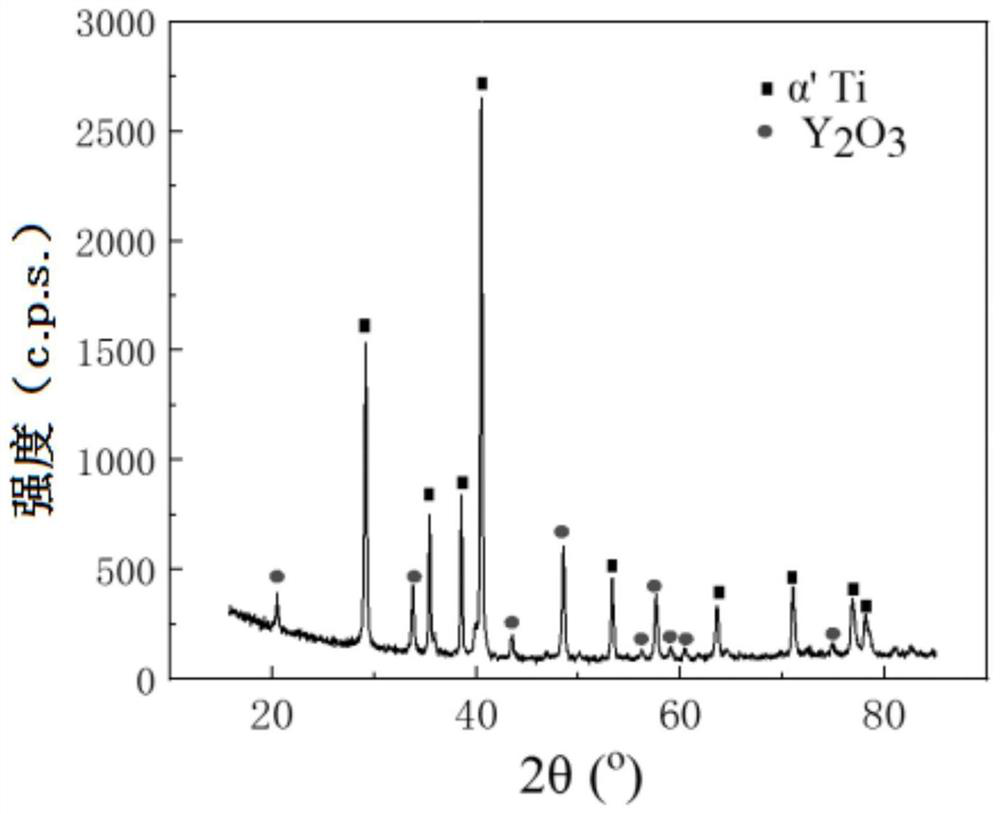

Image

Examples

Embodiment 1

[0019] Embodiment 1: The preparation method of a rare earth oxide reinforced titanium-based composite material of this embodiment is carried out according to the following steps:

[0020] 1. Screen the titanium alloy powder, and screen out the titanium alloy powder with a particle size of 20-75 microns; the elements in the titanium alloy in atomic percent are: Al: 6.0at%, V: 4.5at%, Fe: 0.3at%, the rest is Ti;

[0021] 2. Mix the sieved titanium alloy powder with the rare earth oxide yttrium oxide, put it into a planetary ball mill, and carry out ball milling and powder mixing under the protection of argon to obtain mixed powder; the material ball used in the ball milling is 6mm in diameter and 10mm steel ball, the ratio of ball to material is 15:1, the mixing time of ball milling is 10 hours, and the mass of yttrium oxide accounts for 1% of the mass of titanium alloy powder;

[0022] 3. Transfer the mixed powder obtained in step 2 to the thermal plasma spheroidizing equipmen...

Embodiment 2

[0027] Embodiment 2: The preparation method of a rare earth oxide reinforced titanium-based composite material of this embodiment is carried out according to the following steps:

[0028] 1. Screen the titanium alloy powder, and screen out the titanium alloy powder with a particle size of 20-75 microns; the elements in the titanium alloy in atomic percent are: Al: 6.0at%, V: 4.5at%, Fe: 0.3at%, the rest is Ti;

[0029] 2. Mix the sieved titanium alloy powder with the rare earth oxide yttrium oxide, put it into a planetary ball mill, and carry out ball milling and powder mixing under the protection of argon to obtain mixed powder; the material ball used in the ball milling is 6mm in diameter And 10mm steel ball, the ratio of ball to material is 15:1, the mixing time of ball milling is 10 hours, and the mass of yttrium oxide accounts for 1.5% of the mass of titanium alloy powder;

[0030] 3. Transfer the mixed powder obtained in step 2 to the thermal plasma spheroidizing equipm...

Embodiment 3

[0035] Embodiment 3: The preparation method of a rare earth oxide reinforced titanium-based composite material of this embodiment is carried out according to the following steps:

[0036] 1. Screen the titanium alloy powder, and screen out the titanium alloy powder with a particle size of 20-75 microns; the elements in the titanium alloy in atomic percent are: Al: 6.0at%, V: 4.5at%, Fe: 0.3at%, the rest is Ti;

[0037] 2. Mix the sieved titanium alloy powder with the rare earth oxide yttrium oxide, put it into a planetary ball mill, and carry out ball milling and powder mixing under the protection of argon to obtain mixed powder; the material ball used in the ball milling is 6mm in diameter and 10mm steel ball, the ratio of ball to material is 15:1, the mixing time of ball milling is 10 hours, and the mass of yttrium oxide accounts for 1% of the mass of titanium alloy powder;

[0038] 3. Transfer the mixed powder obtained in step 2 to the thermal plasma spheroidizing equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com