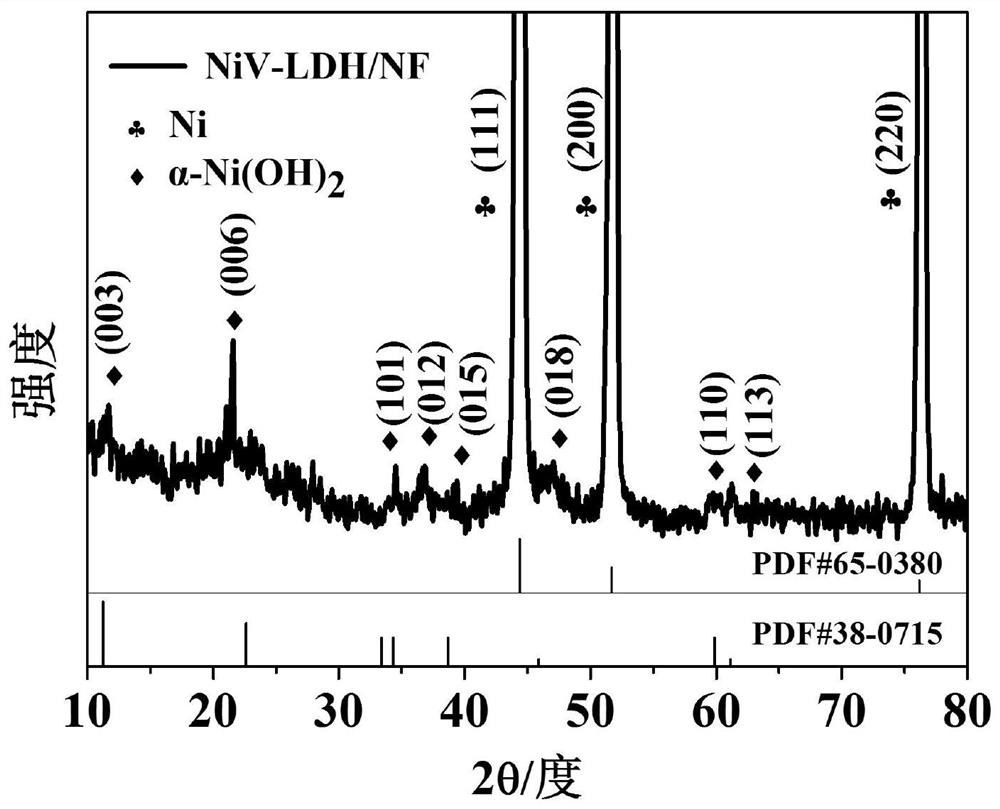

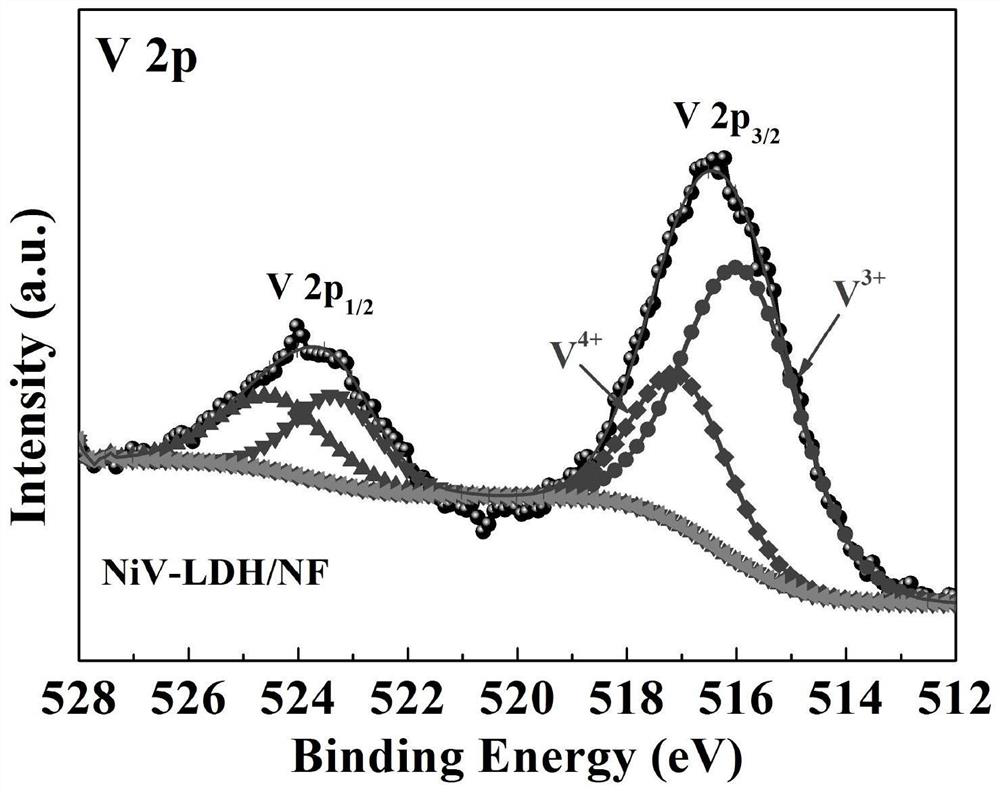

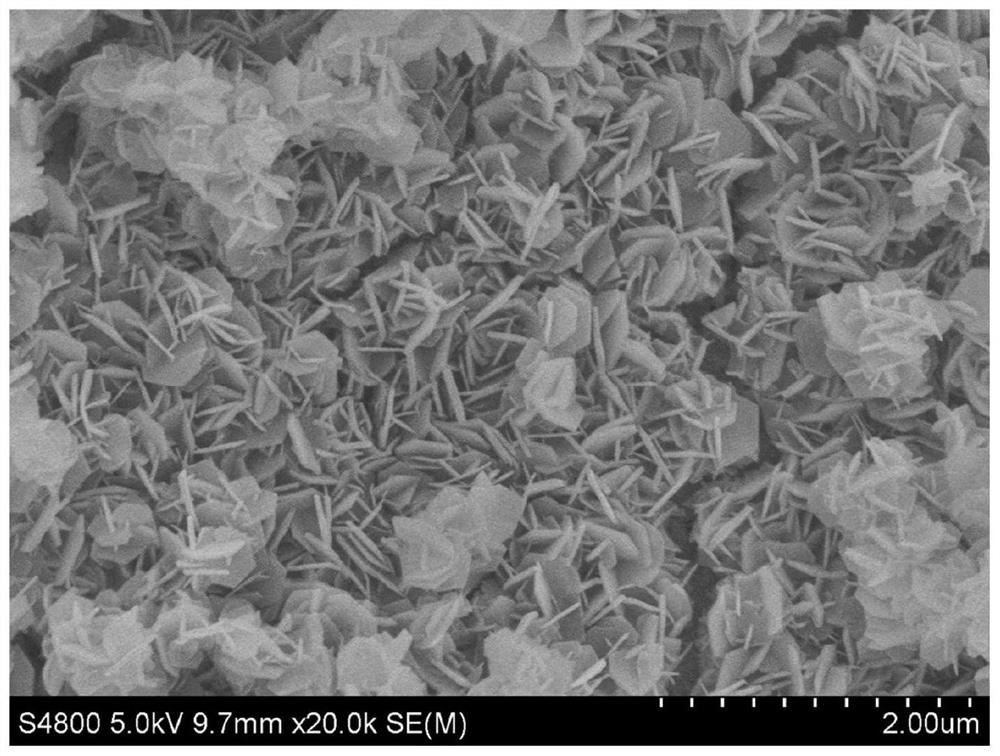

A niv-ldh/nf hydrogen-producing electrode with optimized electronic structure and its preparation method and application

An electronic structure, hydrogen electrode technology, applied in the field of electrocatalytic materials, can solve problems such as difficulty in synthesizing NiV-LDH and slow reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) The cut nickel foam (1cm×5cm) was first ultrasonically cleaned in acetone for 10 minutes, then immersed in a prepared 3mol / L hydrochloric acid solution, ultrasonically cleaned for 5 minutes, and finally rinsed alternately with absolute ethanol and ultrapure water 3 times, then vacuum-dried at 25°C for 12h before use;

[0037] 2) After mixing vanadium chloride and urea uniformly, the molar ratio of vanadium and alkali is 1:1.96, and their masses are 86.5mg and 65mg respectively. After adding 13mg polyvinyl alcohol, pour it into 30mL ultrapure water at the same time. Stir for 30min to obtain solution A;

[0038] 3) Pour solution A into the inner reaction kettle, then put in the prepared nickel foam to soak it and seal it, then fix the inner lining in the outer kettle and place it in an oven with a filling ratio of 60% at 115°C The next reaction is 26h for hydrothermal reaction;

[0039] 4) After the hydrothermal reaction is over, cool to room temperature naturally, and then...

Embodiment 2

[0049] 1) The cut nickel foam (1cm×5cm) was first ultrasonically cleaned in acetone for 15 minutes, then immersed in a prepared 1mol / L hydrochloric acid solution for 10 minutes, and finally washed alternately with absolute ethanol and ultrapure water 2 times, then vacuum drying at 35°C for 10 hours, and then set aside;

[0050] 2) After mixing vanadium chloride and urea uniformly, the molar ratio of vanadium and alkali is 1:4.34, and their masses are 51.5mg and 85mg respectively. After adding 17mg polyvinyl alcohol, pour it into 35mL ultrapure water at the same time. Stir for 10 min to obtain solution A;

[0051] 3) Pour solution A into the inner reaction kettle, then put in the prepared nickel foam to soak it and seal it, then fix the inner lining in the outer kettle and place it in an oven with a filling ratio of 70% at 125°C The next reaction is 22h for hydrothermal reaction;

[0052] 4) After the hydrothermal reaction is over, cool to room temperature naturally, then take out t...

Embodiment 3

[0054] 1) The cut nickel foam (1cm×5cm) was first ultrasonically cleaned in acetone for 11 minutes, then immersed in a prepared 2mol / L hydrochloric acid solution for ultrasonic cleaning for 8 minutes, and finally washed alternately with absolute ethanol and ultrapure water 3 times, then vacuum-dried at 30°C for 11h before use;

[0055] 2) After mixing vanadium chloride and urea uniformly, the molar ratio of vanadium to alkali is 1:2.436 (for example: its mass is 69.0mg and 74.3mg respectively), and after adding 14mg polyvinyl alcohol, pour 31mL of ultrapure at the same time In water, magnetically stirred for 25 min to obtain solution A;

[0056] 3) Pour solution A into the inner reaction kettle, then put in the prepared nickel foam to soak it and seal it, then fix the inner lining in the outer kettle and place it in an oven with a filling ratio of 62% at 117°C Hydrothermal reaction is carried out in the next 25h reaction;

[0057] 4) After the hydrothermal reaction is over, cool to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com