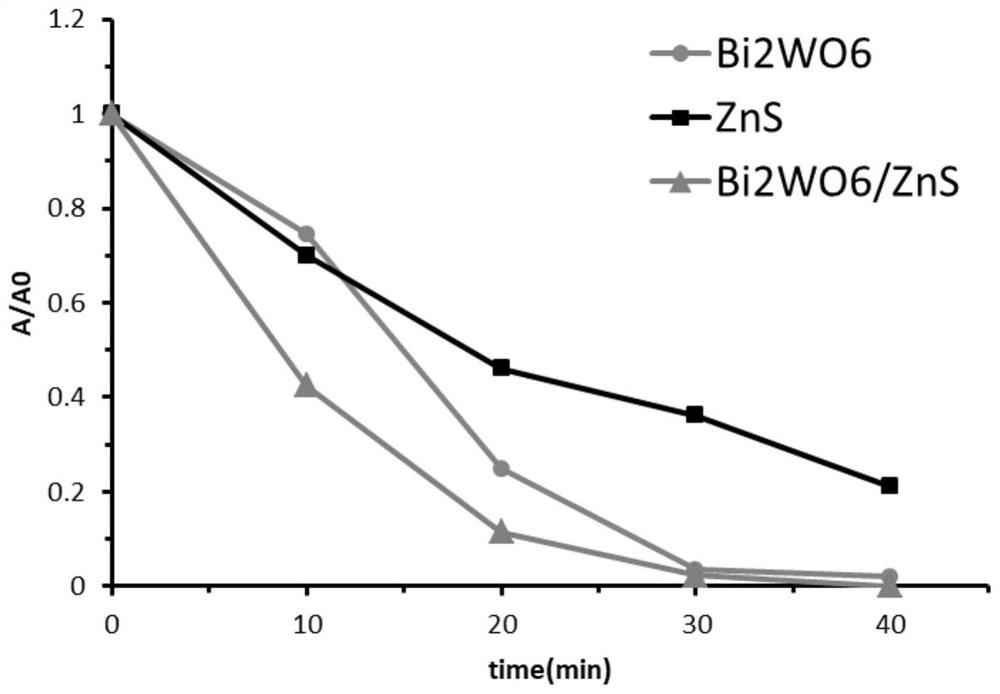

a bi 2 wo 6 /zns heterojunction photocatalyst and preparation method thereof

A photocatalyst, heterojunction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

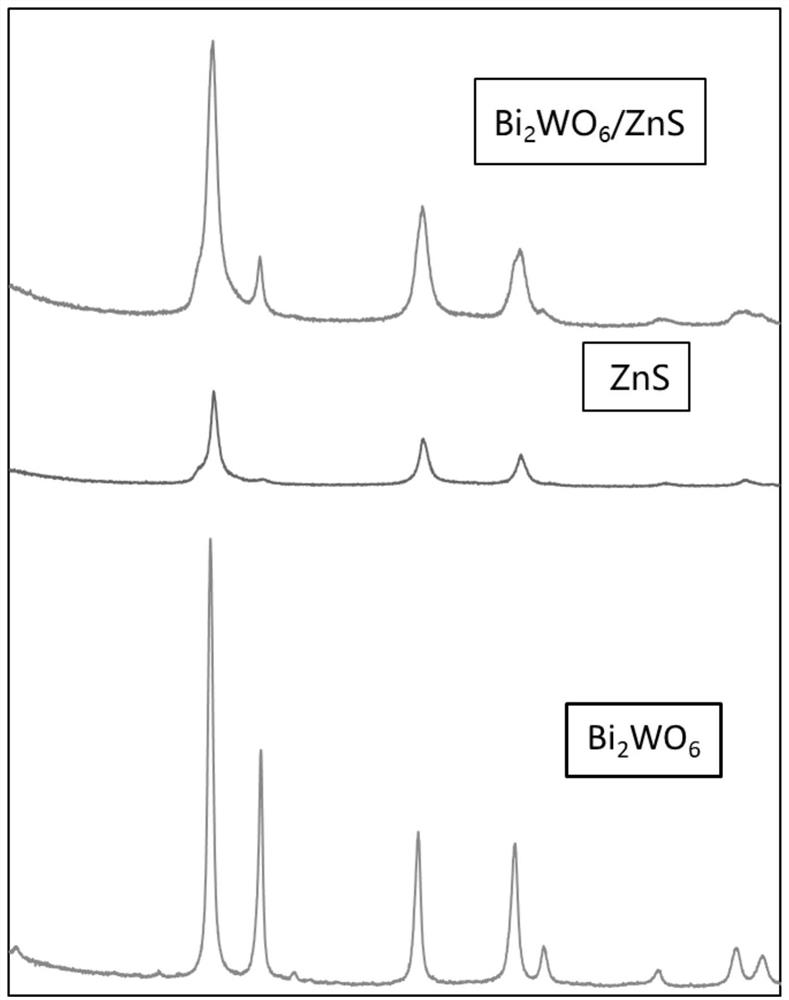

[0030] Bi 2 WO 6 Preparation: Weigh 9.701g of bismuth nitrate pentahydrate and 3.299g of sodium tungstate dihydrate according to the molar ratio of 2:1, dissolve them in 40ml of distilled water (total is 80-100ml), mix the two after completely dissolving, transfer to Put it into a high-pressure hydrothermal reaction kettle, and keep it in a vacuum oven at 150°C for 18h. Naturally cool to room temperature, filter, wash the reaction solid several times with deionized water and absolute ethanol, put it in a vacuum drying oven at 60°C and dry for 5 hours to obtain bismuth tungstate.

[0031] Preparation of ZnS: Put 20mmol of zinc acetate dihydrate and 20mmol of thioacetamide into a beaker respectively, add appropriate amount of deionized water, and magnetically stir to dissolve. Then pour the liquid in the two beakers into a dry and clean 50ml beaker, add 0.5gPVP, stir magnetically for 30min, pour it into a 50ml high-pressure hydrothermal reaction kettle, add water to 95% of the...

Embodiment 1

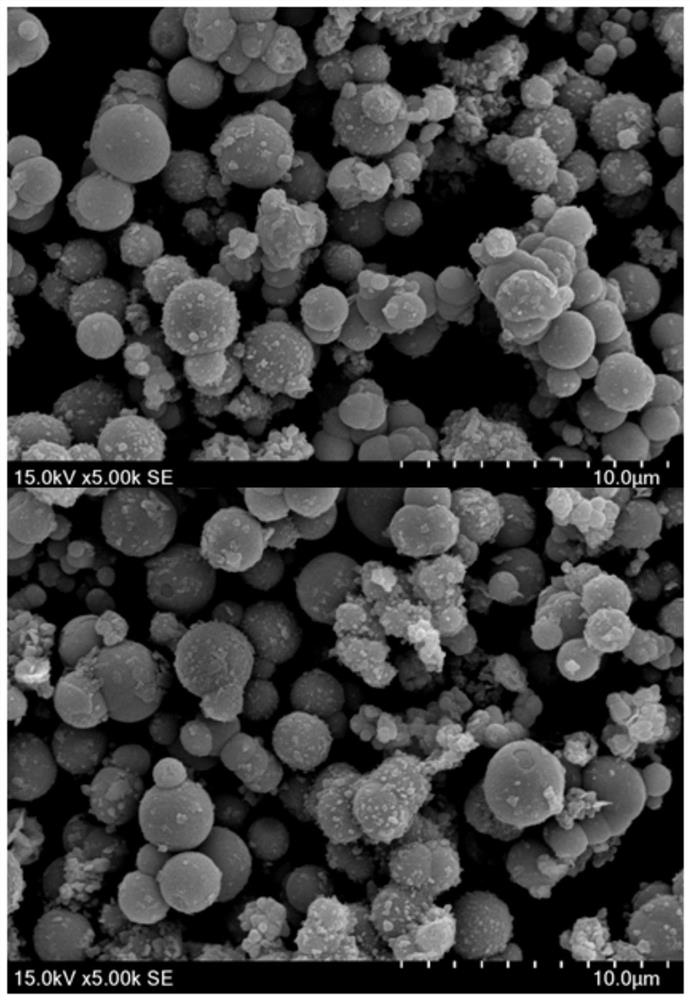

[0035] At room temperature, weigh 0.01g of bismuth tungstate powder and dissolve it in a mixed solvent formed by 10mL of absolute ethanol and 20mL of deionized water, ultrasonically disperse for 30min and mix evenly, then add 0.2g of ZnS powder, stir and mix evenly to obtain a mixed suspension ; The resulting mixed suspension was moved into a 100mL hydrothermal reaction kettle and stirred at 130°C for a hydrothermal reaction for 5h, cooled to room temperature naturally, washed several times alternately with deionized water and absolute ethanol, and placed in a vacuum oven for 60 ℃ drying.

Embodiment 2

[0037] At room temperature, weigh 0.01g of bismuth tungstate solid powder and dissolve it in a mixed solvent formed by 10mL of absolute ethanol and 20mL of deionized water, ultrasonically disperse for 30min and mix evenly, then add 0.1g of ZnS solid powder, stir and mix evenly to obtain a mixed suspension Turbid liquid; transfer the resulting mixed suspension into a 100mL hydrothermal reaction kettle and stir at 130°C for 5h of hydrothermal reaction, naturally cool to room temperature, alternately wash with deionized water and absolute ethanol several times, and place in a vacuum oven Dry at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com