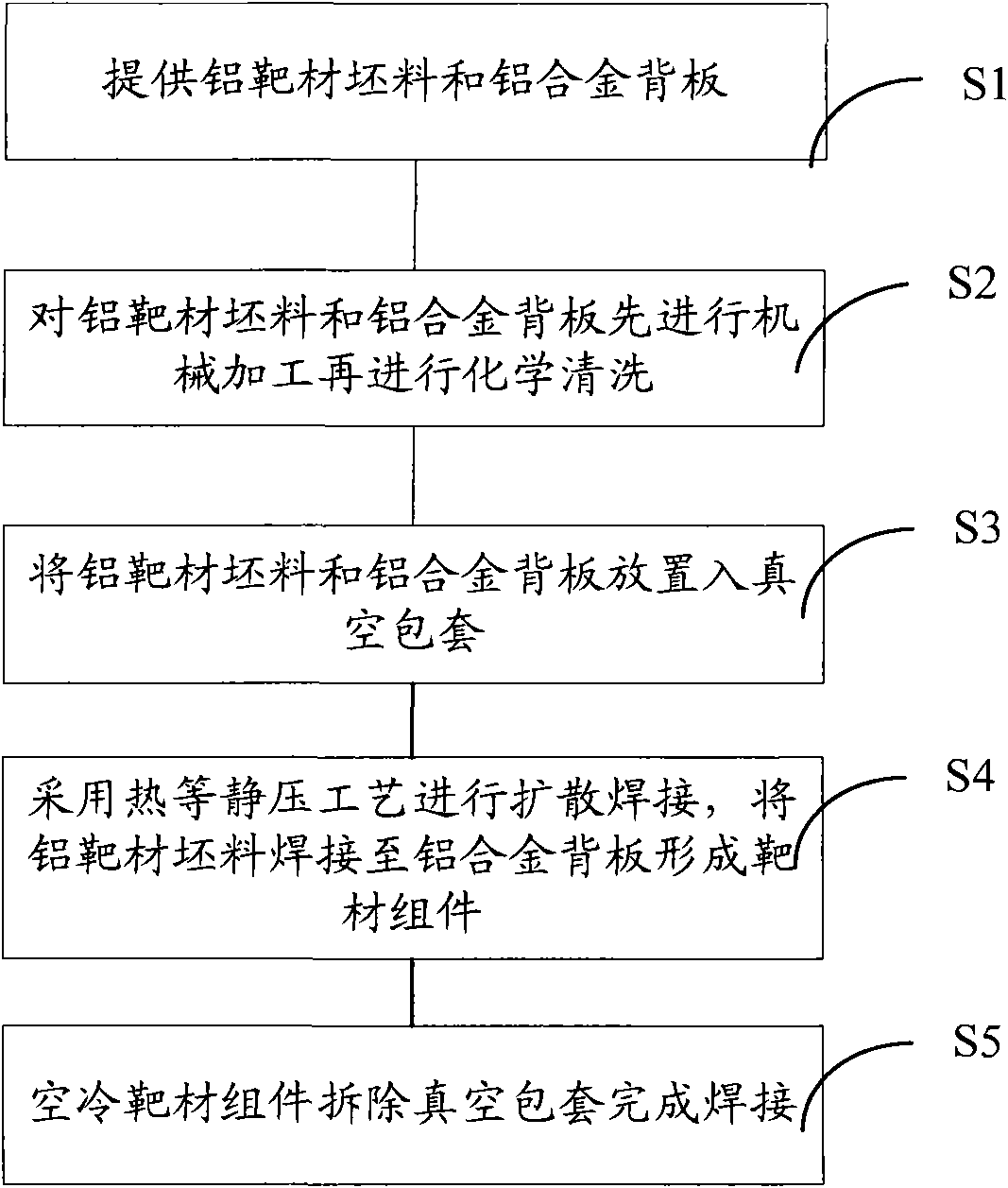

Welding method of aluminum target blank and aluminum alloy backboard

A welding method and aluminum alloy technology, applied in welding equipment, metal material coating process, welding/welding/cutting items, etc., can solve the problems of easy oxidation and affecting the welding effect of target components, etc., and achieve strong resistance to deformation under heat , Prevent oxidation and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The following are the process steps and welding results of diffusion welding between 99.995% high-purity Al target blank and 6061Al alloy back plate:

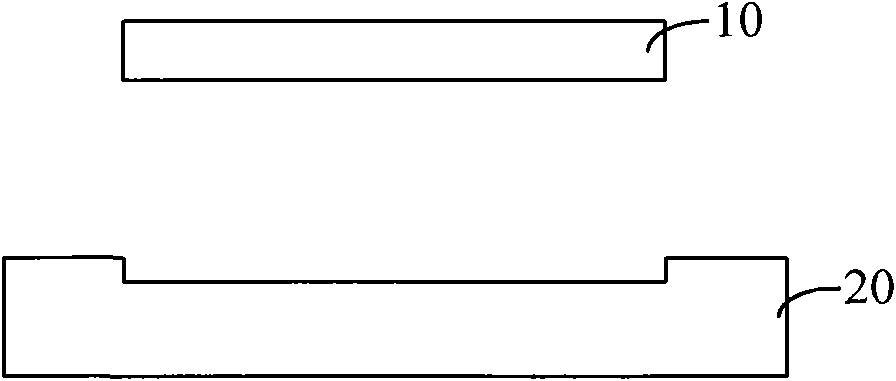

[0035] (1) Surface processing of the target blank and the back plate: machine the surface of the Al target blank and the surface of the 6061Al alloy back plate to make them bright, especially to make the surface finish of the two contact surfaces reach 0.2um.

[0036] (2) Chemical cleaning of the target blank and the back plate: the surface of the Al target blank and the 6061Al alloy back plate is cleaned with an organic solvent to remove soluble impurities on the surface. The organic solvent can be any one of isobutanol IBA, isopropanol IPA or mixed propanol IPB, preferably, isopropanol IPA is selected.

[0037] (3) Put the target blank and back plate into the vacuum bag:

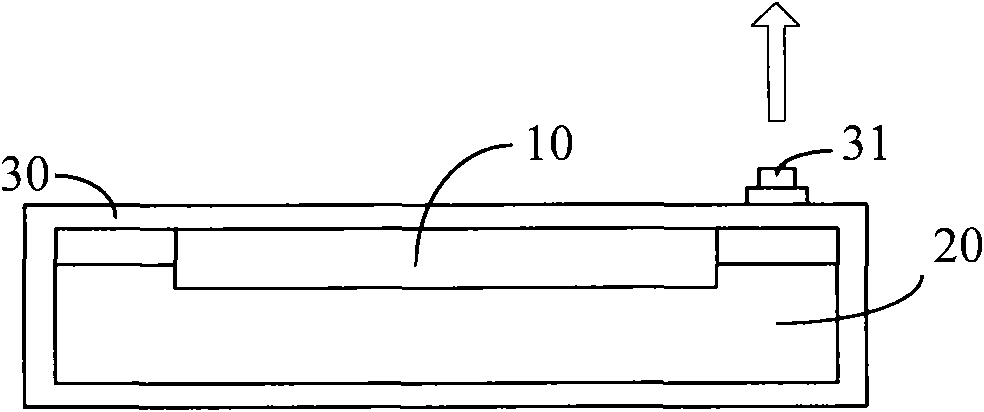

[0038] First put the Al target blank and the 6061Al alloy back plate into a thin-walled vacuum sheath welded and formed, the vacuum sheath is 1.0mm...

Embodiment 2

[0045] The following are the process steps and welding results of diffusion welding between 99.99% high-purity Al target blank and 6061Al alloy back plate:

[0046] (1) Surface processing of the target blank and the back plate: machine the surface of the Al target blank and the surface of the 6061Al alloy back plate to make them bright, especially to make the surface finish of the two contact surfaces reach 3.2um.

[0047] (2) Chemical cleaning of the target blank and the back plate: the surface of the Al target blank and the 6061Al alloy back plate is cleaned with an organic solvent to remove soluble impurities on the surface. The organic solvent can be any one of isobutanol IBA, isopropanol IPA or mixed propanol IPB, preferably, isopropanol IPA is selected.

[0048] (3) Put the target blank and back plate into the vacuum bag:

[0049] First put the Al target blank and the 6061Al alloy back plate into a thin-walled vacuum sheath welded and formed, the vacuum sheath is 1.0mm ...

Embodiment 3

[0056] The following are the process steps and welding results of diffusion welding between 99.99% high-purity Al target blank and ZL105AL alloy back plate:

[0057] (1) Surface processing of the target blank and the back plate: machine the surface of the Al target blank and the surface of the ZL105AL alloy back plate to make them bright, especially to make the surface finish of the two contact surfaces reach 1.6um.

[0058] (2) Chemical cleaning of the target blank and the back plate: Clean the surface of the Al target blank and the ZL105AL alloy back plate with an organic solvent to remove soluble impurities on the surface. The organic solvent can be any one of isobutanol IBA, isopropanol IPA or mixed propanol IPB, preferably, isopropanol IPA is selected.

[0059] (3) Put the target blank and back plate into the vacuum bag:

[0060] First put the Al target blank and the ZL105AL alloy back plate into a thin-walled vacuum sheath welded and formed by welding 1.0mm to 2.0mm low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com