Ultrasonic degas method for quartz continuous melting furnace

A continuous melting furnace and ultrasonic technology, applied in glass furnace equipment, glass manufacturing equipment, glass forming, etc., can solve the problems of unusable stirring, prominent airtight problems, narrow space of tungsten crucible, etc., to reduce processing work and enhance mechanical strength , the effect of high scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

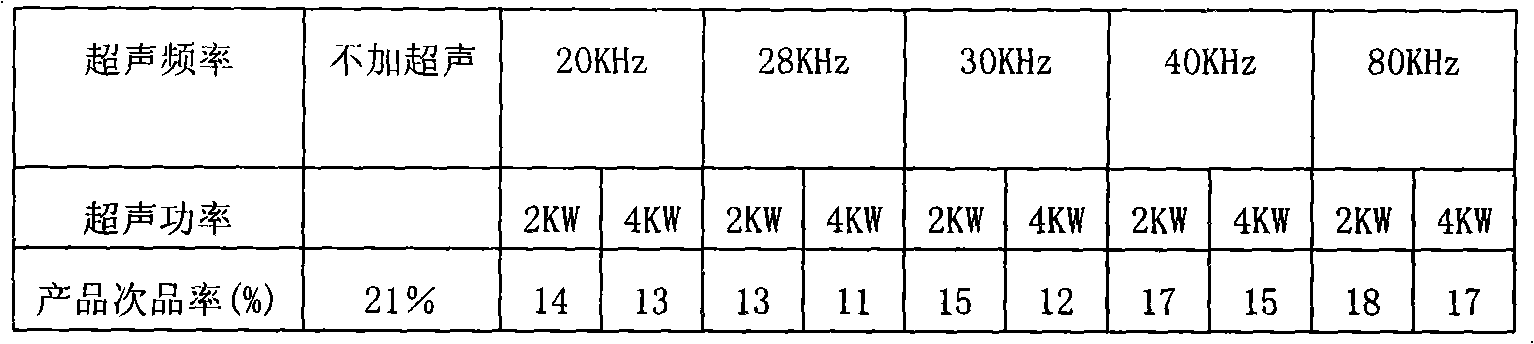

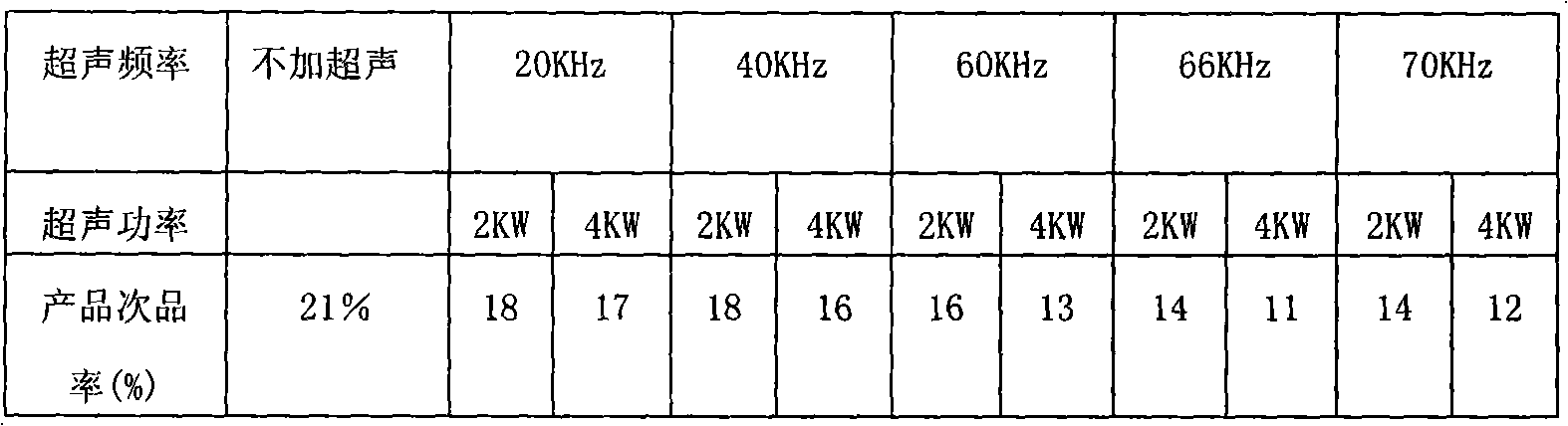

[0012] A method for ultrasonic degassing in a quartz continuous furnace. The energy of the ultrasonic transducer is transmitted to the quartz slurry inside the crucible through an ultrasonic conducting rod, and the mechanical energy and harmonic characteristics of the ultrasonic wave The bubbles are exhausted ultrasonically and the ultrasonic bubbles are crushed and ablated to achieve the purpose of degassing. The ultrasonic conducting rod is provided with two sections A and B. Section A is a hollow tube filled with high-temperature silicone oil, and section B is Solid rod body, the inner end of the solid rod body of section B is fixedly connected with the crucible as a whole, the outer end of the tube of section A is connected with the ultrasonic transducer, and a circulating cooling device is provided outside the tube of section A. To prevent ultrasonic waves from generating standing waves at the junction of sections A and B, it is necessary to ensure that the actual transmissio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com