Wool-fabric biological anti-felting method based on cutinase, keratinase and protease treatment

A technology of keratinase and protease, which is applied in the field of biological anti-felting of wool fabrics based on cutinase, keratinase and protease treatment, can solve the problems of large damage to anti-felting fibers and environmental pollution, and achieve low fiber damage and better wetting The effect of shortening the time and improving the dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

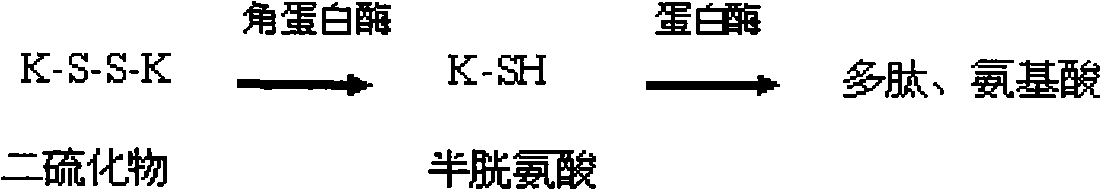

Method used

Image

Examples

Embodiment 1

[0019] Fabric Variety: All-wool gabardine.

[0020] (1) Extraction pretreatment: the wool fabric is placed in chloroform:methanol (87:13, v / v) organic solvent, reflux extraction at 55°C for 4 hours, and then washed with ethanol and hot water to remove residual impurities on the cloth surface.

[0021] (2) Oxidation treatment: treatment bath: 30% hydrogen peroxide 20g / L, solution of wetting and penetrating agent 0g / L, temperature 50°C, pH 8.0, treatment time 0.5 hours.

[0022] (3) Cutinase treatment: treatment bath: cutinase 5.0% owf, solution of wetting and penetrating agent 0 g / L, temperature 60° C., pH 8.0, treatment time 4 hours.

[0023] (4) Keratinase treatment: treatment bath: solution of cutinase 5.0% owf, wetting and penetrating agent 0 g / L, temperature 55° C., pH 8.5, time 8 hours.

[0024] (5) Protease treatment: treatment bath: 2% owf of protease, 0 g / L solution of wetting and penetrating agent, 55° C., pH 8.5, treatment time 1 hour.

[0025] Sample 1: Oxidation ...

Embodiment 2

[0029] Fabric type: all-wool women's clothing.

[0030] (1) Extraction pretreatment: the wool fabric is placed in carbon tetrachloride: methanol (87:13, v / v) organic solvent solution, refluxed and extracted at 55°C for 4 hours, and then washed with ethanol and hot water to remove the cloth Impurities remain on the surface.

[0031] (2) Cutinase treatment: treatment bath: solution of cutinase 2.0% owf, wetting and penetrating agent 1 g / L, temperature 60° C., pH 8.0, treatment time 4 hours.

[0032] (3) Keratinase treatment: treatment bath: solution of cutinase 5.0% owf, wetting and penetrating agent 0 g / L, temperature 55° C., pH 8.5, time 8 hours.

[0033] (4) Protease treatment: treatment bath: protease 1% owf solution, 55° C., pH 8.5, treatment time 1 hour.

[0034] Sample 1: treated with two baths of cutinase and protease (steps 1, 2 and 4);

[0035] Sample 2: Three-step treatment with cutinase, keratinase pretreatment and protease (steps 1, 2, 3 and 4).

[0036] After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com