New disposal method of fly ash

A treatment method and technology for fly ash, applied in the removal of solid waste, cement production, etc., can solve the problem of difficulty in handling fly ash, and achieve the effect of ensuring harmless treatment, no secondary pollution, and continuous process.

Active Publication Date: 2011-01-05

BEIJING BBMG BEISHUI ENVIROMENTAL TECH CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is mainly to solve the problem that the fly ash after garbage incineration is difficult to handle, and to provide a new treatment method for fly ash, that is, a method combining high temperature incineration and cement solidification

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

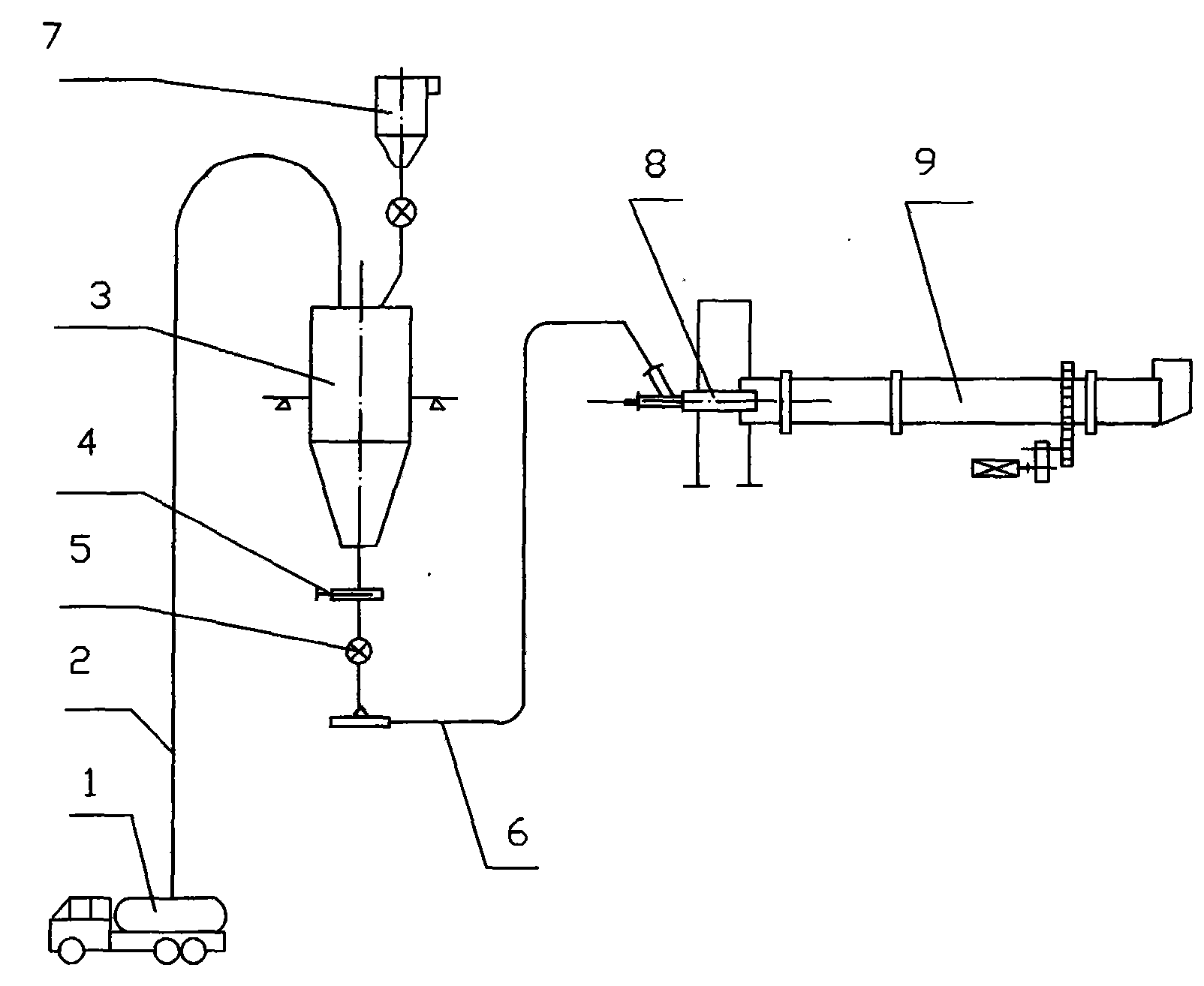

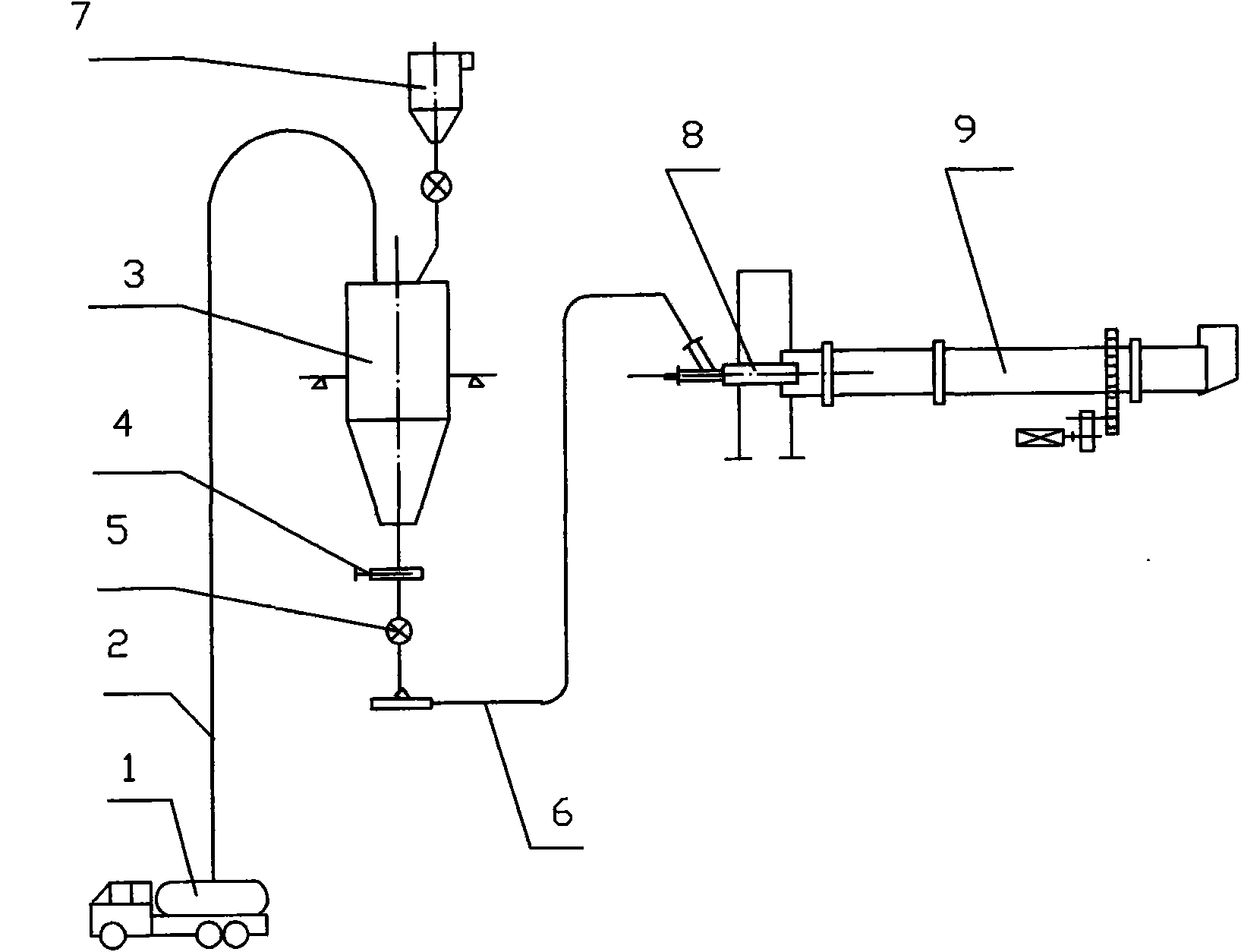

The invention relates to a new disposal method of fly ash, including the following technical process: a tank truck after pulling in a factory drives the fly ash into an ash storage bin by vacuum pressure carried by the tank; a gauging device in the ash storage bin controls the discharge amount of the fly ash, and then the fly ash goes into a pneumatic transportation bin; the fly ash of the pneumatic transportation bin is transported to a combustor or a spray gun of kiln hood by pneumatic power and then is sprayed into a rotary kiln for incineration by the combustor or the spray gun; heavy metal in the fly ash is solidified into the composition of cement and can not be separated out; and poisonous and pernicious dioxin contained in the fly ash is completely broken down into water and carbonoxide and the like at high temperature in the kiln. The invention has the advantages that: spraying point is arranged at the kiln hood, thus effectively realizing innocent treatment of the poisonousand pernicious dioxin in the fly ash; the heavy metal is solidified by the cement, can not be separated out and finally is contained in the cement product, thus realizing waste utilization without secondary pollution; the technique is novel, unique, simple and practical; the process is continuous, automatic, safe and reliable.

Description

A New Treatment Method of Fly Ash technical field The invention relates to a treatment method of fly ash, in particular to a new treatment method of fly ash. Background technique Because the fly ash produced after garbage incineration has the characteristics of various types of heavy metals, a high proportion, a large amount of chloride ions, and highly toxic and harmful dioxins, etc., ordinary disposal methods cannot achieve harmless disposal. Waste incineration is an advanced waste reduction technology at home and abroad. Waste incineration During the incineration process, the incineration residue collected by the flue gas cleaning system is called waste incineration fly ash. Because fly ash contains organic pollutants such as benzopyrene, benzanthracene, and dioxin, and heavy metals such as Cr, Cd, Hg, Pb, Cu, and Ni, it is a hazardous solid waste, so direct landfilling will pollute groundwater. The cost of building a dedicated landfill is high, and it takes up a lot ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B09B3/00

CPCC04B7/26Y02P40/10C04B7/367

Inventor 熊云贵张觊蔡金山

Owner BEIJING BBMG BEISHUI ENVIROMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com