Method for preparing nanometer calcium carbonate special for water soluble ink by wet method

A technology of nano-calcium carbonate and water-based ink, applied in the direction of calcium carbonate/strontium/barium, ink, application, etc., can solve problems such as foaming, easy migration, and insufficient whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

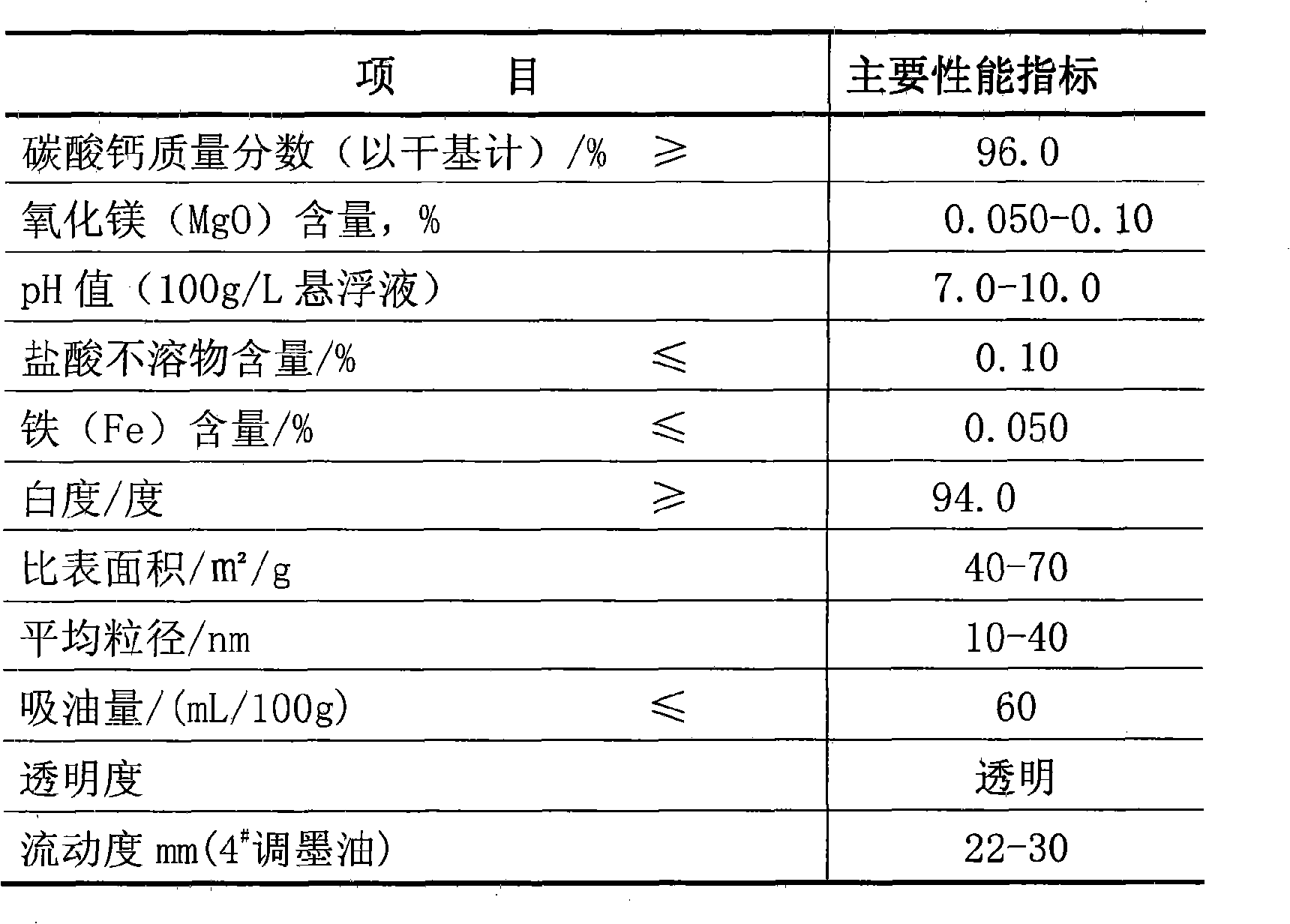

Image

Examples

Embodiment 1

[0035] The limestone is crushed by the jaw crusher to a size of 30×100mm, and is conveyed to the top hopper of the shaft kiln by the conveyor belt. The low-grade limestone is calcined by an environmentally friendly and energy-saving steel shaft kiln. The calcining temperature is controlled between 950 and 1050°C. The time is 18-30 hours.

[0036]The calcined lime is screened, high-quality lime is selected for crushing, and then enters the digester for lime digestion. The temperature of the water for digesting lime is controlled at 65°C, and the dosage is 7 times the mass of lime. The primary lime slurry contains some coarse slag, and the concentration of calcium hydroxide is 13%. The undigested burnt lime, silicon dioxide, magnesium oxide and other impurities are removed by hydrocyclone separation and vibrating sieving to obtain a fine slurry.

[0037] The prepared seminal pulp is kept warm and aged by using the waste heat when digesting lime. After aging for 24 hours, add w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com