Halogen-free fire retardation thermoplastic polyurethane plastic and preparation method thereof

A thermoplastic polyurethane and polyurethane technology, which is applied in the field of halogen-free flame retardant thermoplastic polyurethane plastics, can solve the problems of TPU's great influence on mechanical properties and difficult mixing of TPU.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] TPU: Taiwan Coating, ER-85A (polyether TPU)

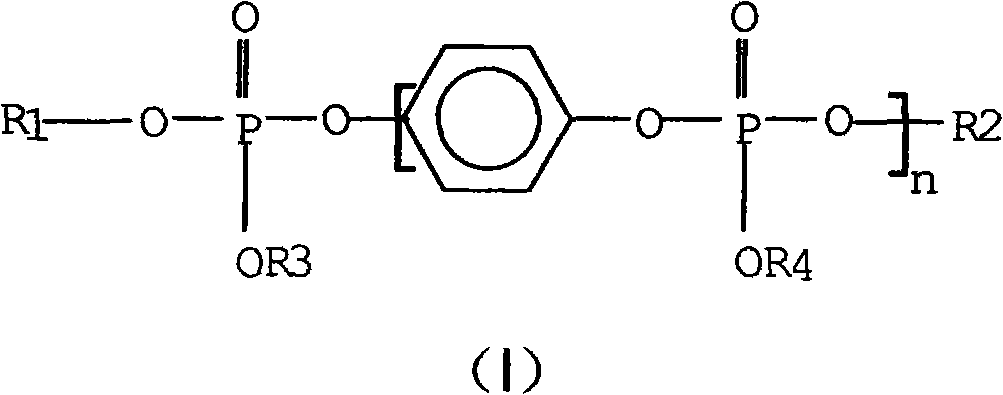

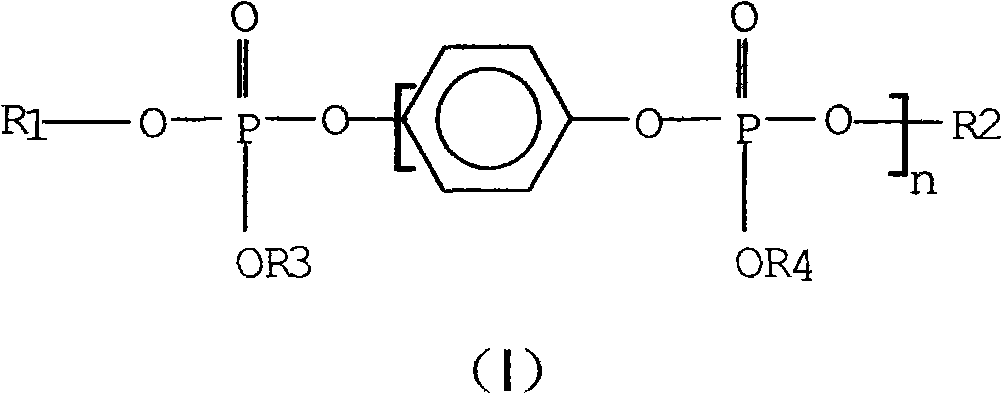

[0023] Flame retardant A: hydroquinone bis(dimethylphenyl) diphosphate, which meets the requirements of structural formula I,

[0024] R1~R4 are all dimethylphenyl, n=1, melting point 9°C

[0025] Flame retardant B: resorcinol bis(diphenyl) diphosphate (RDP),

[0026] Viscosity (40°C): 600cps

[0027] Flame retardant C: triphenyl phosphate, analytically pure, Shanghai Chemical Reagent Store, melting point 4°C Add 700 parts of TPU and 300 parts of flame retardant A into TSSJ25 / 40 twin-screw extruder, temperature 1°C, screw speed 200rpm, strand cutting, vacuum drying at 9°C for 4 hours, sample testing according to ISO standard.

Embodiment 2

[0033] Flame retardant: hydroquinone bis(phenyl) diphosphate, meeting the requirements of structural formula I, R1~R4 are all phenyl groups, n=10

[0034] Add 600 parts of polyester TPU, 200 parts of flame retardant, and 200 parts of calcium carbonate into a TSSJ25 / 40 twin-screw extruder at a temperature of 200°C and a screw speed of 200rpm, pelletize strands, and vacuum dry at 9°C for 4 hours. According to the ISO standard proofing test, it is very easy to feed materials during processing, the flame retardancy has passed the UL94-V0 test, and there is no precipitation of flame retardants.

Embodiment 3

[0036] Flame retardant: hydroquinone bis(dimethylphenyl) diphosphate, meeting the requirements of structural formula I, R1~R4 are all dimethylphenyl, n=1, melting point 9°C

[0037] Add 400 parts of polyester TPU, 400 parts of polycarbonate TPU, 50 parts of flame retardant, and 150 parts of montmorillonite into the TSSJ25 / 40 twin-screw extruder at a temperature of 1 °C and a screw speed of 200 rpm. Granules, vacuum-dried at 9°C for 4 hours, tested according to ISO standards, feeding is very easy during processing, the flame retardancy has passed the UL94-V0 test, and there is no precipitation of flame retardants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com