Porefilling heat curing resin composition

A resin composition and thermosetting technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of PCT resistance decline, printed circuit board insulation reliability deterioration, etc., and achieve small change rate of thermal expansion rate, high density Excellent compatibility and high glass transition point

Active Publication Date: 2012-05-30

TAIYO HLDG CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

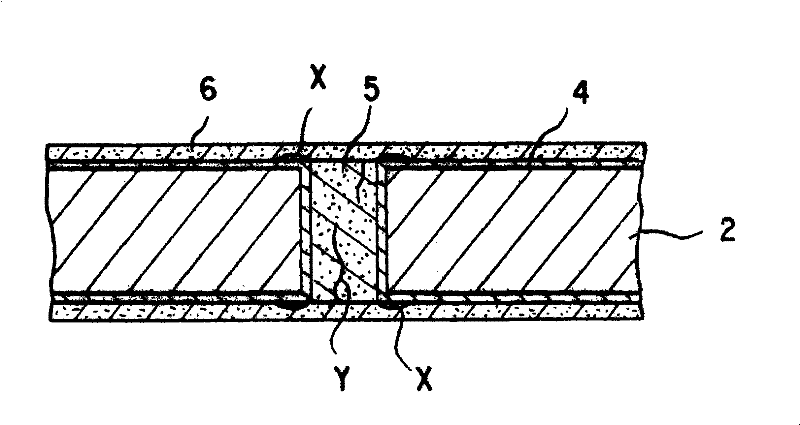

[0009] However, as described above, in the case of using an epoxy resin composition different from that for solder resist for hole filling of printed wiring boards, under high temperature conditions such as curing treatment and solder leveling, such as figure 2 As shown, there are cracks in the hole insulating layer 5 (internal crack Y), and peeling (delamination X) between the peripheral portion of the hole insulating layer 5 and the outer insulating layer 6 (solder resist or insulating resin layer). question

When such cracks and delaminations occur, the PCT resistance (pressure cooker test resistance) under high temperature and high humidity will decrease, and the insulation reliability of the printed wiring board will deteriorate.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~7

[0108] The components listed in the following Table 1 were blended in the ratio shown in Table 1, pre-mixed, and then kneaded and dispersed with a 3-roll mill to obtain a thermosetting resin composition for hole filling. The multifunctional epoxy resin in Table 1 refers to the epoxy resin with more than 3 functional groups.

[0109] Table 1

[0110]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a porefilling heat curing resin composition, a combined unit with photo-curing heat curing resin composition for forming solder mask, and a printed circuit board using these. The heat curing resin composition for stuffing hole parts of the printed circuit board is a heat curing resin composition which contains epoxy resin, epoxy curing agent and inorganic filler andis stuffed in the hole part of the printed circuit board, which is characterized in that the epoxy resin contains epoxy resin with two functional groups and epoxy resin with more than three functionalgroup, the inorganic filler contains periodic table IIa family elemental salts. In addition, in the combined unit using the porefilling heat curing resin composition, the photo-curing heat curing resin composition II for forming solder mask contains a light polymerization initiator with the decomposition temperature more than 250 DEG C.

Description

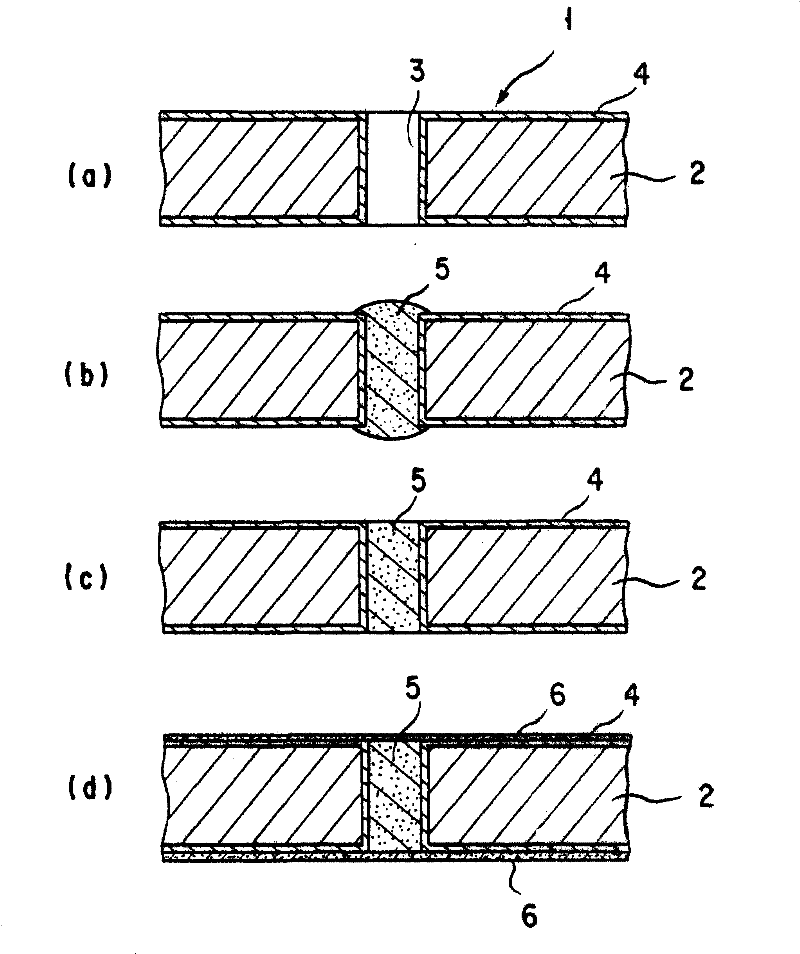

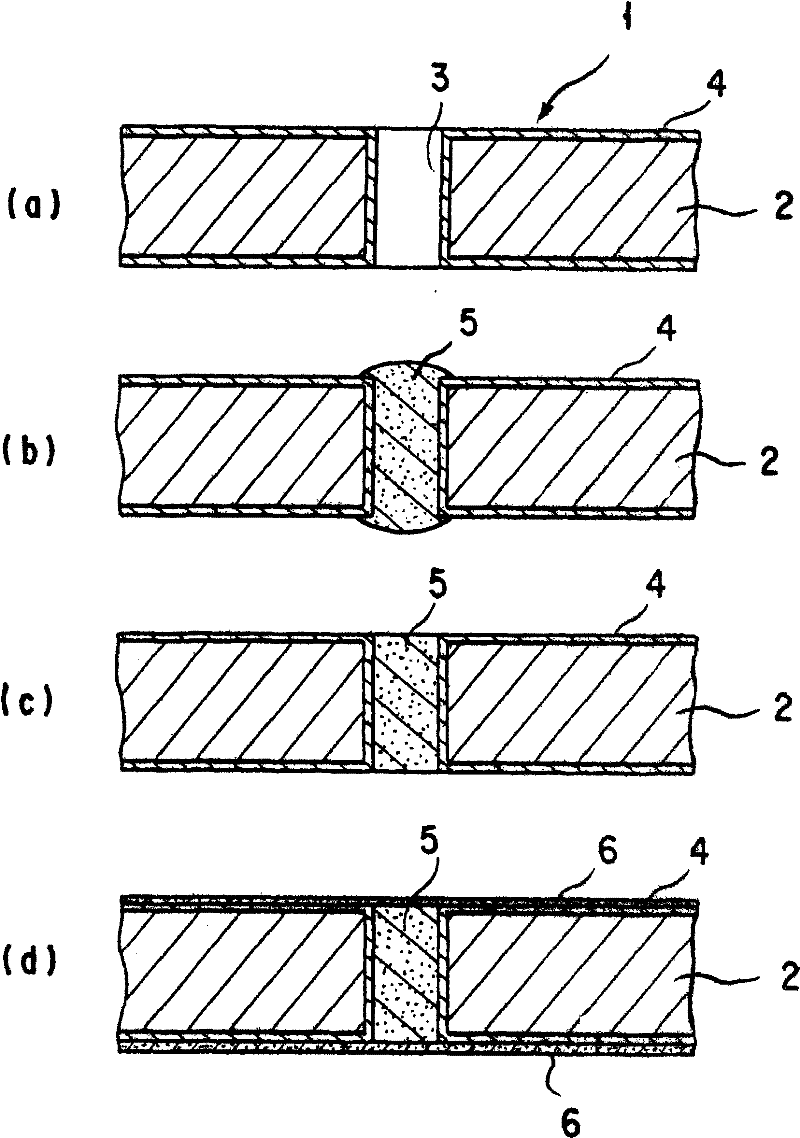

technical field [0001] The present invention relates to a thermosetting resin composition for hole filling, a combination unit of the composition and a photocurable thermosetting resin composition for solder resist formation, and a printed wiring board. Specifically, it relates to a liquid thermosetting resin composition useful as a composition for permanently filling through holes, via holes, etc. in printed wiring boards such as multilayer substrates and double-sided substrates , and a combined unit of the composition and a photocurable thermosetting resin composition for solder resist formation, and a printed circuit for permanent filling of through holes and via holes and solder resist formation using the composition or the combined unit plate. [0002] In addition, in this specification, a "hole part" is a term which collectively names through-holes, via holes, and the like formed during the production process of a printed wiring board. Background technique [0003] A...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L63/00C08K3/10H05K1/03

Inventor 远藤新柴田大介邑田胜人

Owner TAIYO HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com