White adhesive for flexible printed circuit and preparation method thereof

A flexible printed circuit and adhesive technology, applied in the directions of adhesives, adhesive types, polyether adhesives, etc., can solve the problems of light shading and low light reflectivity, and achieve the effect of high light reflectivity, simplified process and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A white adhesive for flexible printed circuits, its raw material components include thermosetting resin, filler, thermoplastic resin, rubber, curing agent and curing accelerator, wherein:

[0054] The thermosetting resin is novolac epoxy resin

[0055] The filler is a mixture of titanium dioxide and aluminum hydroxide or

[0056] The thermoplastic resin is 4-hydroxymethylphenoxymethyl resin of phenoxy resin

[0057] The rubber is carboxylated nitrile rubber 1072CG

[0058] The curing agent is 4-methyltetrahydrophthalic anhydride

[0059] The curing accelerator is 1 cyano 2-ethyl 4-methylimidazole

[0060] The organic solvent is a mixture of butanone and N,N-dimethylformamide

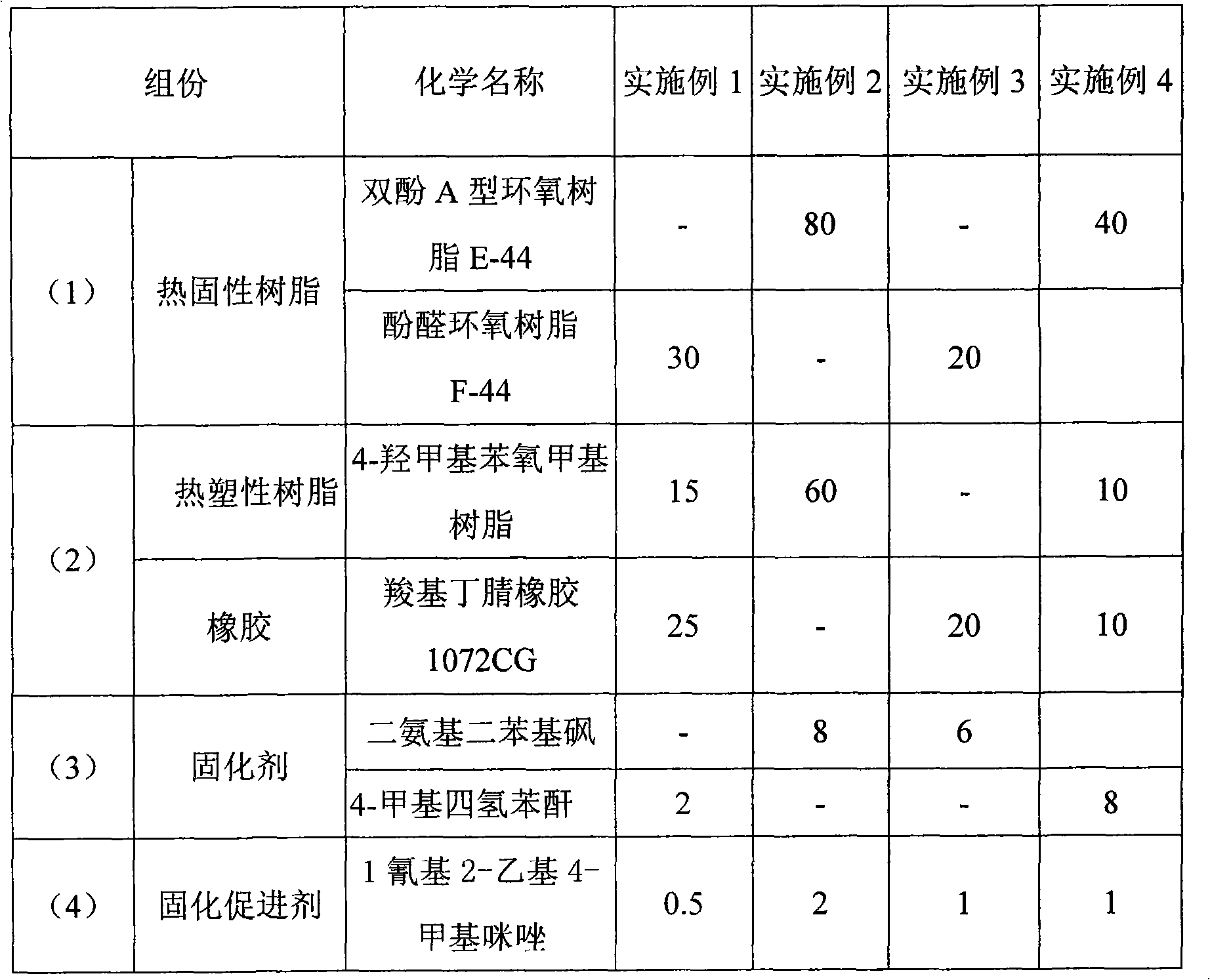

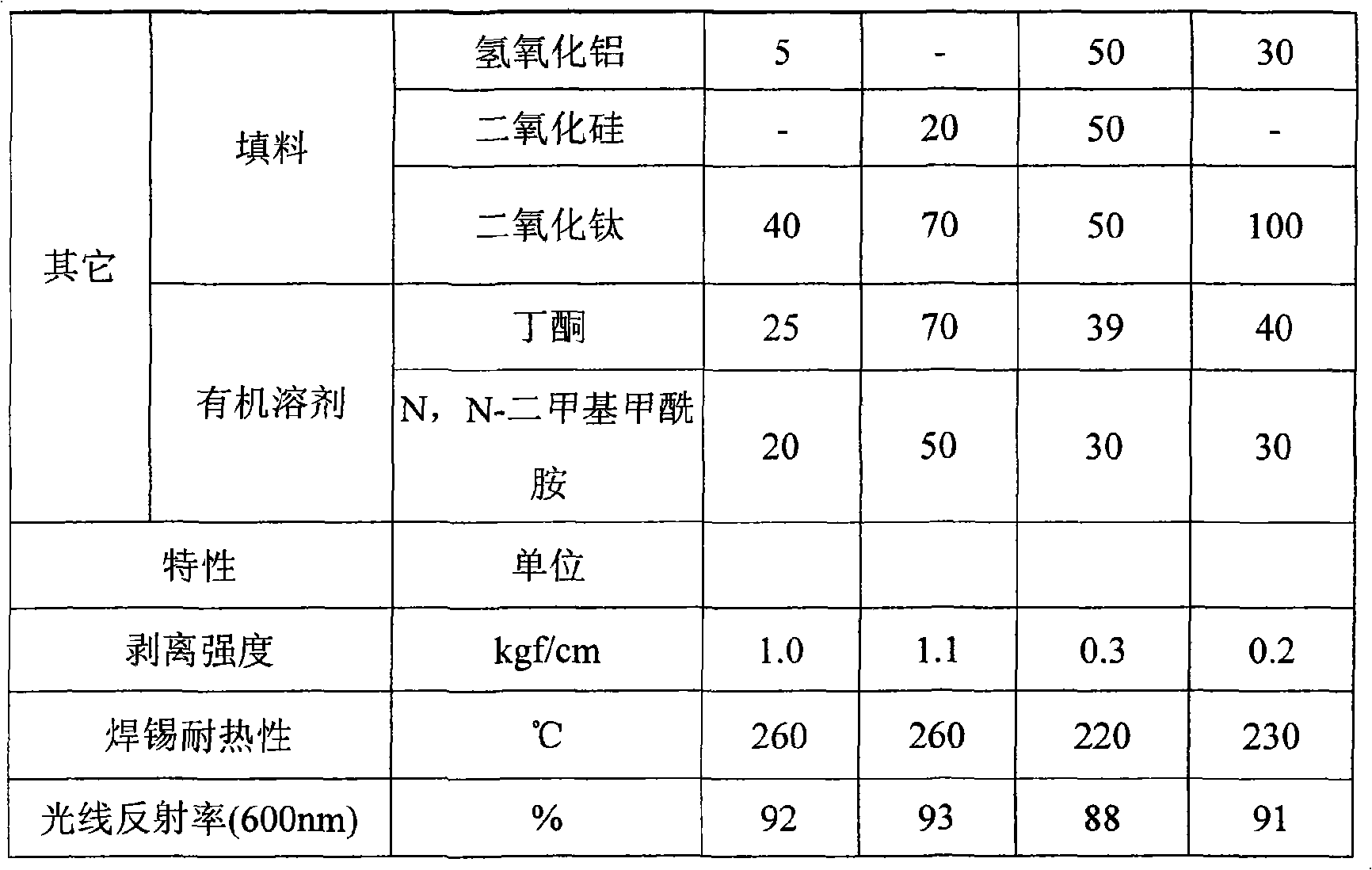

[0061] See Table 1 for the weight ratio of each raw material component.

[0062] The preparation method of the white adhesive for above-mentioned flexible printed circuit, it comprises the steps:

[0063] (1) Dissolving the thermosetting resin, thermoplastic resin and rubber in the organic s...

Embodiment 2

[0073] A kind of white adhesive for flexible printed circuit, its raw material component comprises:

[0074] The thermosetting resin is bisphenol A type epoxy resin E-44

[0075] The filler is a mixture of titanium dioxide and silicon dioxide

[0076] The thermoplastic resin is 4-hydroxymethylphenoxymethyl resin of phenoxy resin

[0077] The curing agent is diaminodiphenyl sulfone

[0078] The curing accelerator is 1 cyano 2-ethyl 4-methylimidazole

[0079] The organic solvent is a mixture of butanone and N,N-dimethylformamide

[0080] See Table 1 for the weight ratio of each raw material component.

[0081] Except that the mixing ratio of each component of the white adhesive mixture and the organic solvent is listed as the ratio in the column of Example 2 in Table 1, the preparation of the white cover film material is the same as in Example 1, and also according to the following The described test method was used to test the characteristics of this flexible copper clad l...

Embodiment 3

[0083] Except that the mixing ratio of each component of the white adhesive mixture and the organic solvent is listed as the ratio in the column of Example 3 in Table 1, the preparation of the white cover film material is the same as in Example 1, and also according to the following The described test method was used to test the characteristics of this white cover film material, and the results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com