Processing technique of naphthalene water-reducing agent or its homologous dispersant

A naphthalene-based water reducer and production process technology, applied in the field of water reducer production, can solve problems such as large quality fluctuations, adverse effects on equipment life, and high labor intensity of workers, so as to reduce labor intensity and human factors, and facilitate stability and process control, prolonging the effect of equipment service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is a production process of a naphthalene-based high-efficiency water reducer:

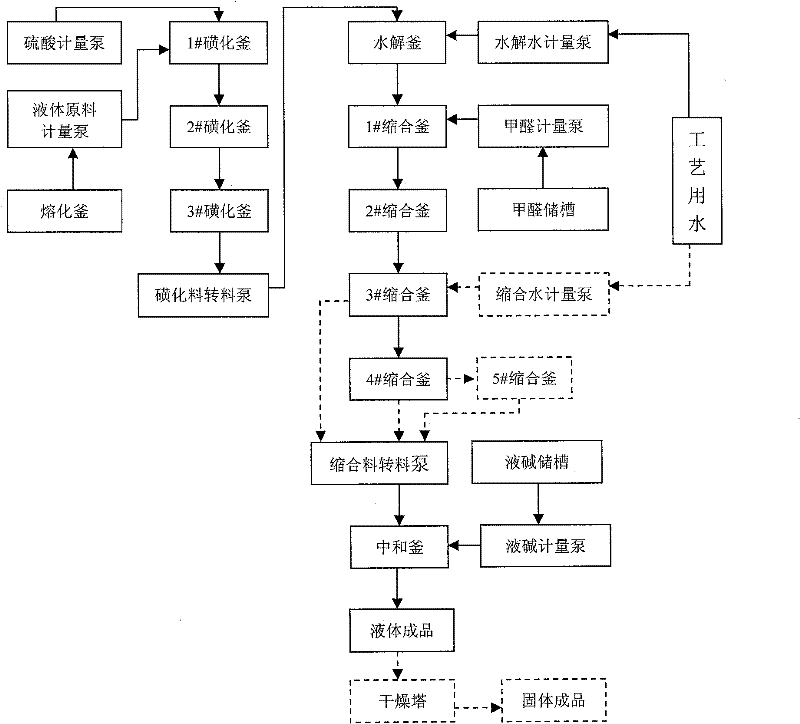

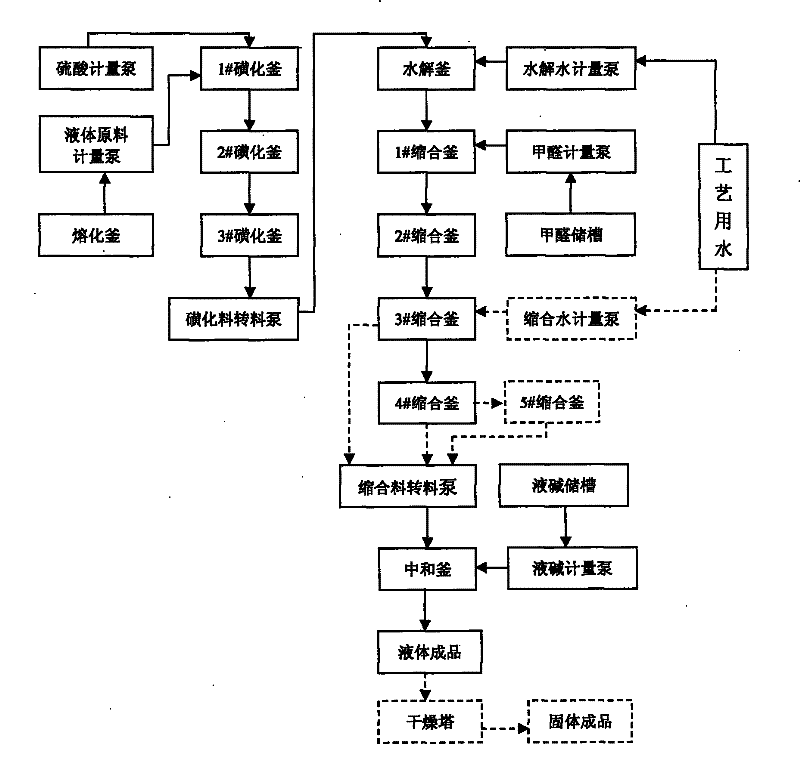

[0046] Such as figure 1 As shown in the process flow, it includes main steps such as melting naphthalene, sulfonation reaction, hydrolysis reaction, condensation reaction, and neutralization reaction; the sulfonation reaction is a three-stage sulfonation reaction, and the condensation reaction is a four-stage condensation reaction. The specific operation of each step is as follows:

[0047] (1) Fused naphthalene:

[0048] Concentrate industrial naphthalene in a melting pot to melt naphthalene, and obtain molten industrial naphthalene at 100°C;

[0049] (2) Tertiary sulfonation reaction:

[0050] a. The first stage sulfonation reaction:

[0051]Put the liquid industrial naphthalene in the molten state obtained in the above step (1) into the 1# sulfonation kettle at 50kg / h through the liquid raw material metering pump, and simultaneously put sulfuric acid into the 1# sulfon...

Embodiment 2

[0071] This example is a production process of a solid naphthalene-based high-efficiency water reducer:

[0072] Such as figure 1 As shown in the process flow, it includes main steps such as melting naphthalene, sulfonation reaction, hydrolysis reaction, condensation reaction, and neutralization reaction; the sulfonation reaction is a three-stage sulfonation reaction, and the condensation reaction is a four-stage condensation reaction. The specific operation of each step is as follows:

[0073] (1) Fused naphthalene:

[0074] Concentrate industrial naphthalene in a melting pot to melt naphthalene, and obtain molten industrial naphthalene at 100°C;

[0075] (2) Tertiary sulfonation reaction:

[0076] a. The first stage sulfonation reaction:

[0077] Put the liquid industrial naphthalene in the molten state obtained in the above step (1) into the 1# sulfonation kettle through the liquid raw material metering pump at 50kg / h, and simultaneously put sulfuric acid into the 1# su...

Embodiment 3

[0098] This embodiment is a production process of a solid industrial acenaphthene high-efficiency water reducer:

[0099] Such as figure 1 As shown in the process flow, it includes the main steps of melting acenaphthene, sulfonation reaction, hydrolysis reaction, condensation reaction, and neutralization reaction; the sulfonation reaction is a three-stage sulfonation reaction, and the condensation reaction is a three-stage condensation reaction. The specific operation of each step is as follows:

[0100] (1) Fused acenaphthene:

[0101] Concentrate industrial acenaphthene in a melting kettle to melt acenaphthene, and obtain liquid industrial acenaphthene in a molten state at 90°C;

[0102] (2) Tertiary sulfonation reaction:

[0103] a. The first stage sulfonation reaction:

[0104] Put the liquid industrial acenaphthene in the molten state obtained in the above step (1) into the 1# sulfonation kettle at 100kg / h through the liquid raw material metering pump, and simultaneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com