Cylindrical single-phase permanent magnet linear synchronous motor with parallel magnetic circuits and propulsion control system thereof

A single-phase permanent magnet, cylindrical technology, applied in the direction of propulsion systems, electric components, electrical components, etc., can solve the problems of difficult processing of permanent magnet brackets, large secondary pole distance requirements, complex processing technology, etc., and achieve structural High strength and reliability, large eddy current solution, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

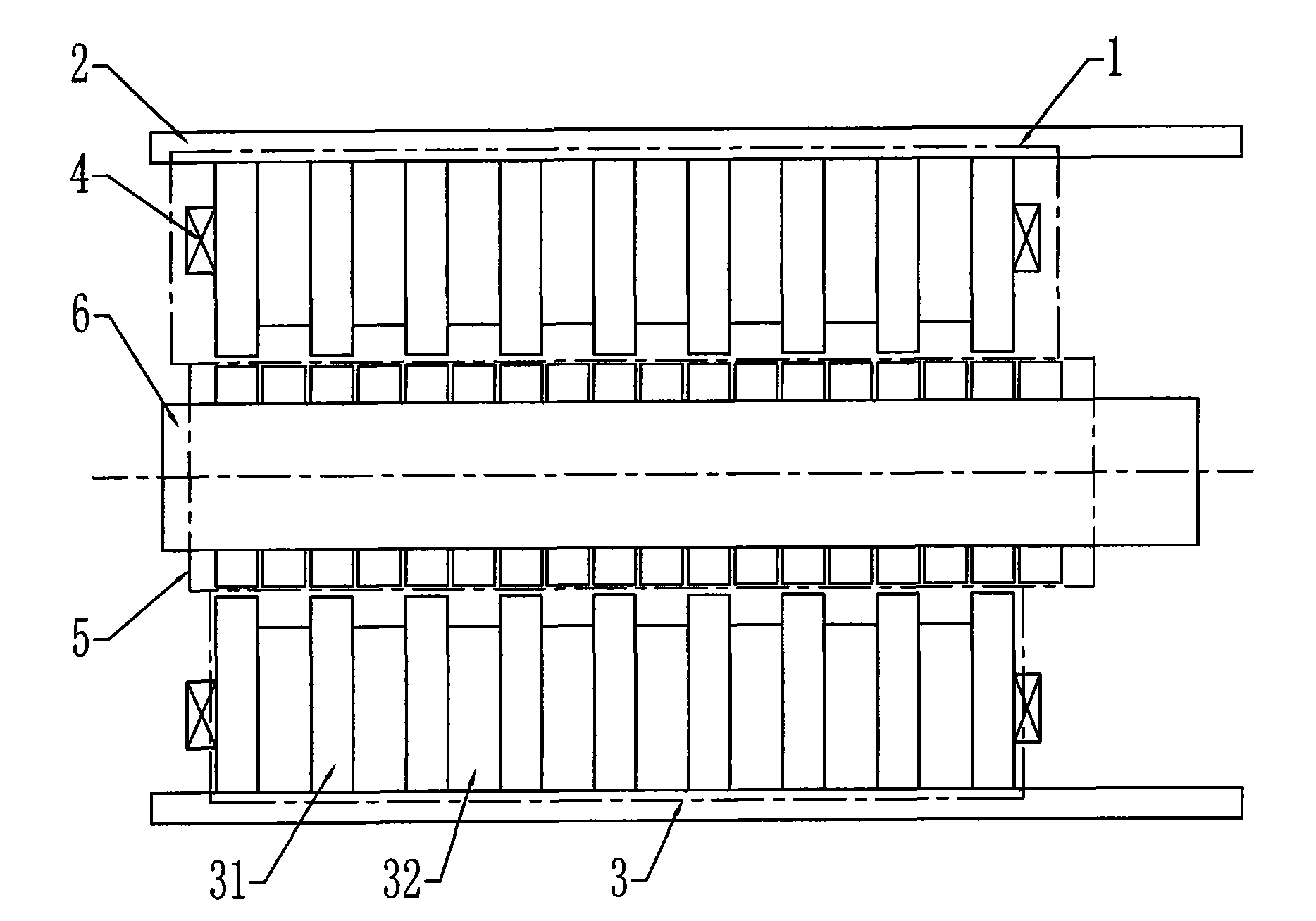

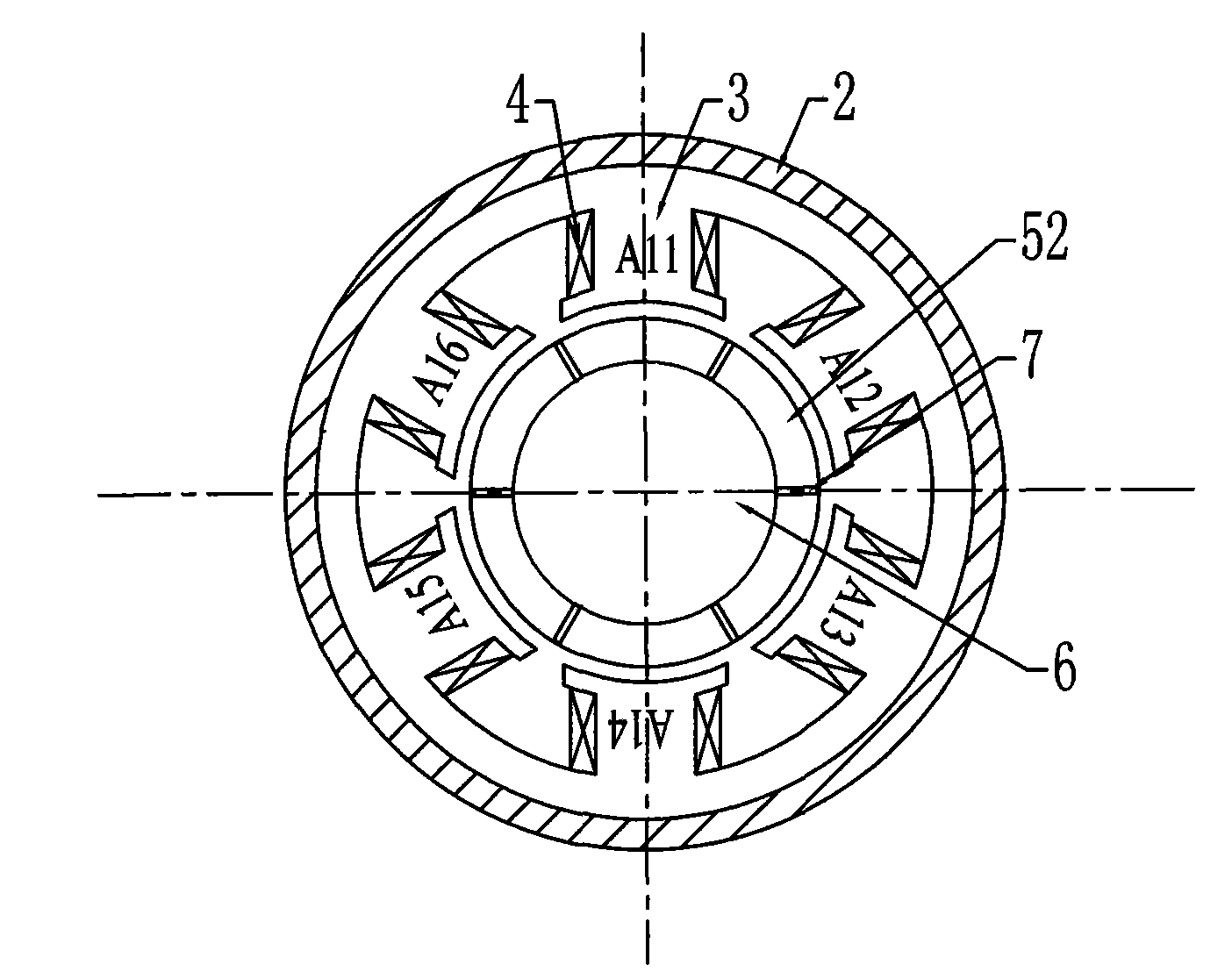

[0009] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes primary, secondary, air gap and mover support leaf spring; secondary includes permanent magnet array 5 and shaft tube 6; permanent magnet array 5 is fixedly arranged on shaft tube 6; primary includes electrical Armature 1 and casing 2; armature 1 includes armature core 3 and armature winding 4; armature core 3 includes i+1 annular core segments 31 and i core segment spacer rings 32, where i is a positive integer ; The i+1 annular iron core segments 31 and i iron core segment spacer rings 32 are arranged at intervals along the axial direction; the sum of the axial thicknesses of an annular iron core segment 31 and an iron core segment spacer ring 32 is equal to 2τ p , where τ p is the pole pitch of the permanent magnet; the inner circumference of each armature core 3 is evenly opened with 2n slots along the axial direction, wherein n is a positive intege...

specific Embodiment approach 2

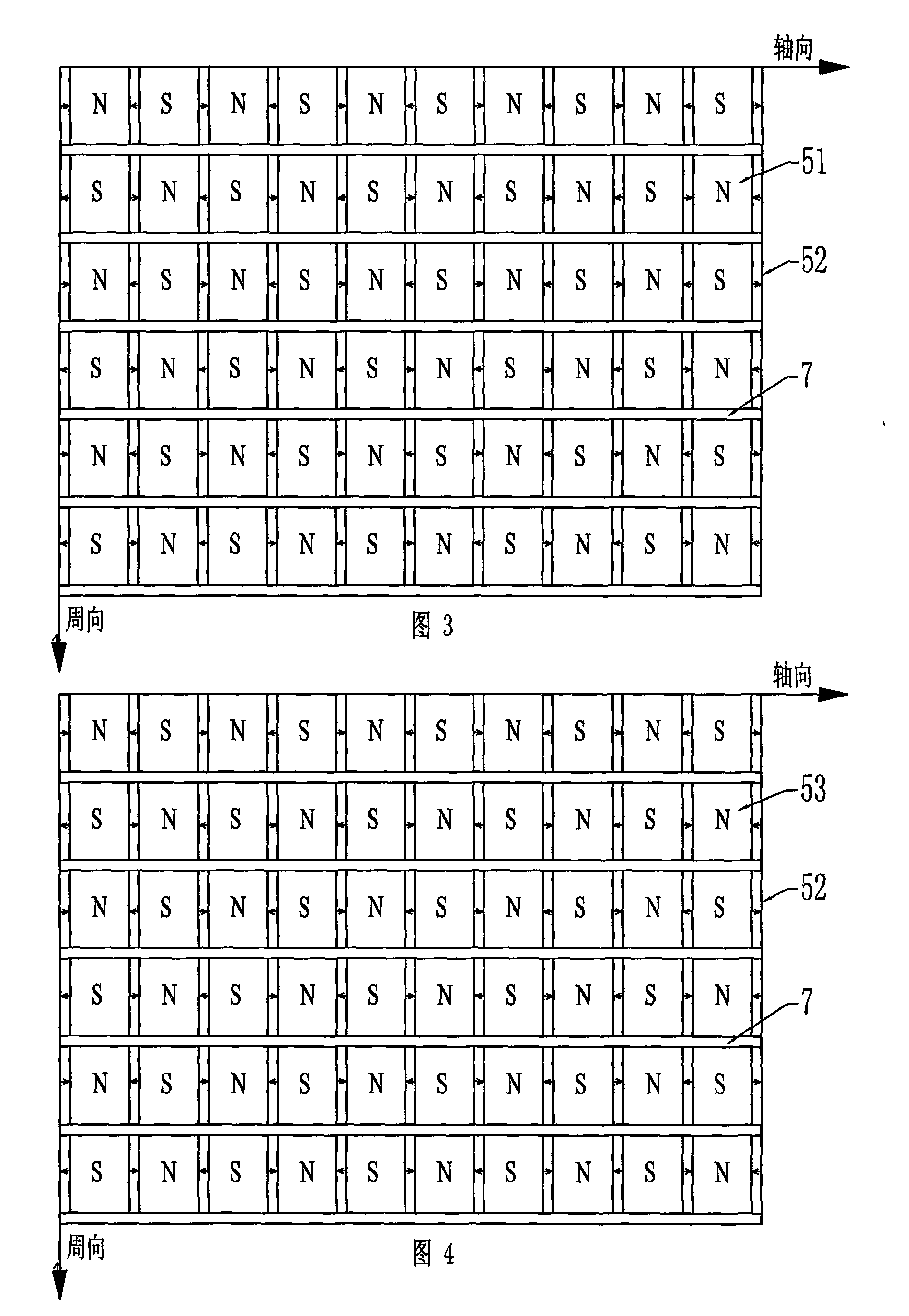

[0010] Specific implementation mode two: combination image 3 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the secondary also includes 2n non-magnetic spacers 7, and the permanent magnet array 5 includes m sector-shaped permanent magnets 52 and m-1 tile-shaped permanent magnets 51 , sector-shaped permanent magnets 52 are axially magnetized, tile-shaped permanent magnets 51 are radially magnetized, and m sector-shaped permanent magnets 52 and m-1 tile-shaped permanent magnets 51 are arranged alternately along the axial direction to form a row of permanent magnet strips , 2n columns of permanent magnet strips and 2n non-magnetic spacer strips 7 are arranged alternately along the circumferential direction, and the magnetization directions of the two adjacent sector permanent magnets 52 in the axial or circumferential direction are opposite; The magnetization directions of the two tile-shaped permanent magnets 51 are opposite...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination Figure 4 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the secondary also includes 2n non-magnetic spacers 7, and the permanent magnet array 5 includes m sector-shaped permanent magnets 52 and m-1 tile-shaped magnetic permeable yokes 53. Sector-shaped permanent magnets 52 are axially magnetized. m sector-shaped permanent magnets 52 and m-1 tile-shaped magnetic yokes 53 are arranged alternately in the axial direction to form a row of permanent magnet strips, and 2n columns of permanent magnet strips are connected to 2n non-magnetic strips. The magnetic spacer bars 7 are arranged alternately along the circumferential direction, and the magnetization directions of the two sector-shaped permanent magnets 52 adjacent to each other in the axial or circumferential direction are opposite. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com