Polymer reversed phase bonding extraction column and method for extracting gold from alkaline cyanide solution using the column

A reversed-phase bonding, solid-phase extraction column technology, applied in the direction of chemical instruments and methods, other chemical processes, and process efficiency improvement, can solve the problems of narrow pH range and easy failure of working materials, and achieve a wide pH range, The effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

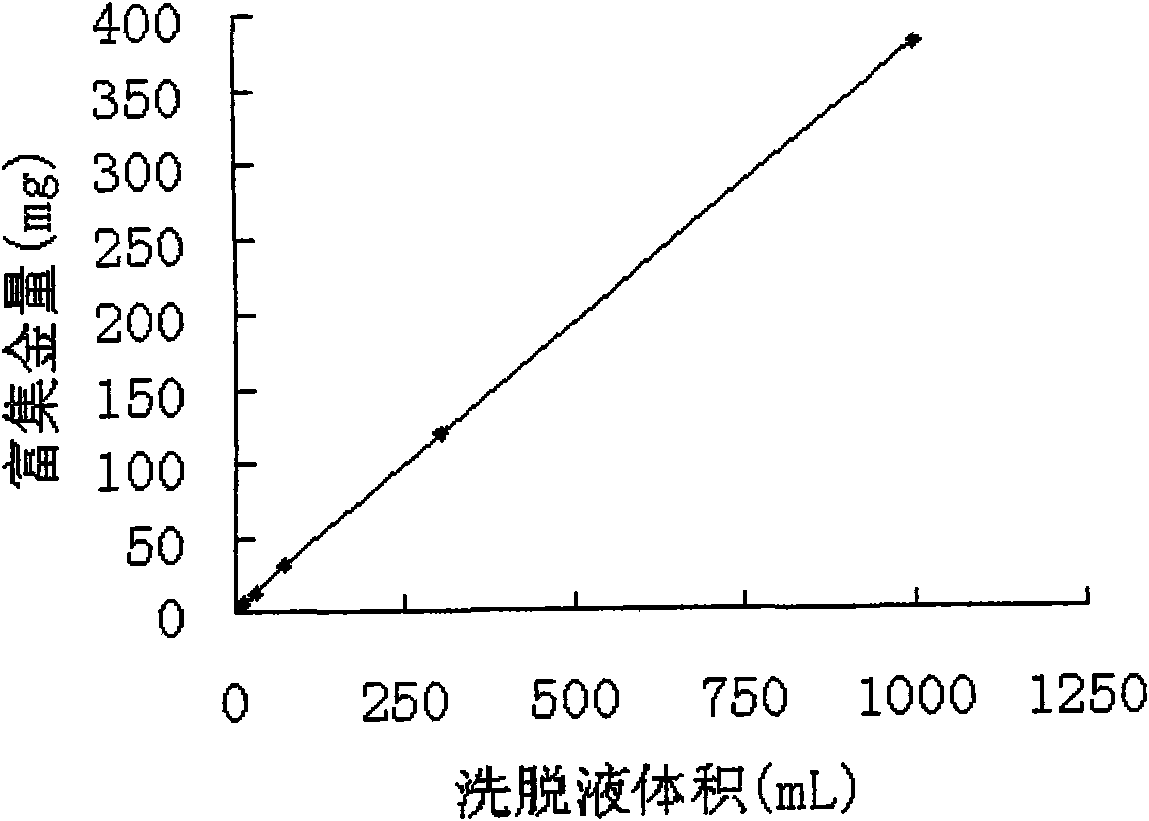

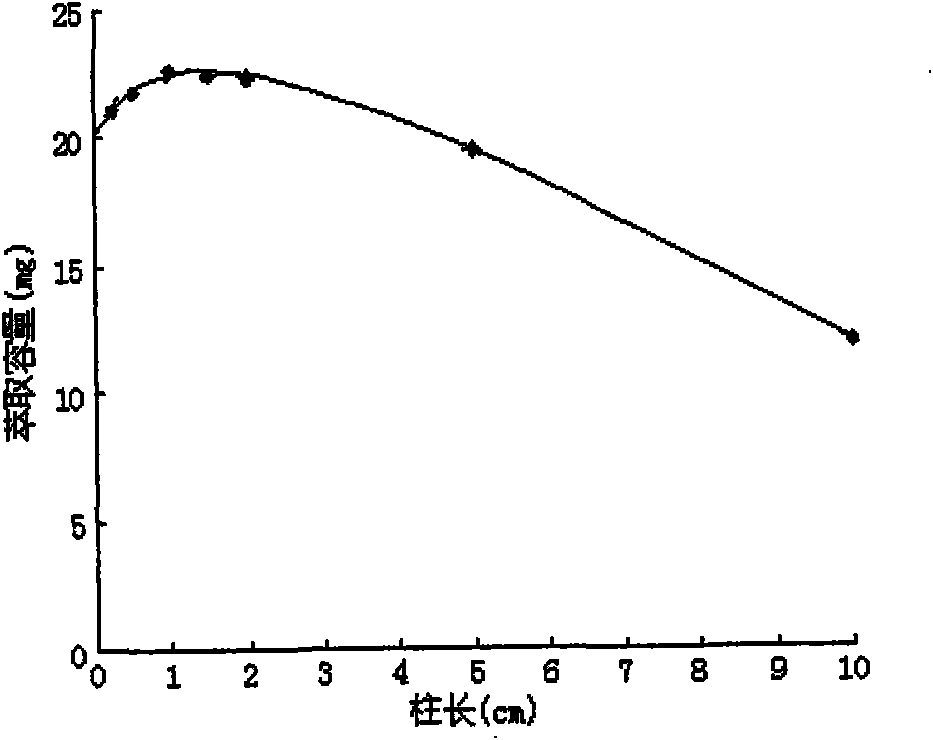

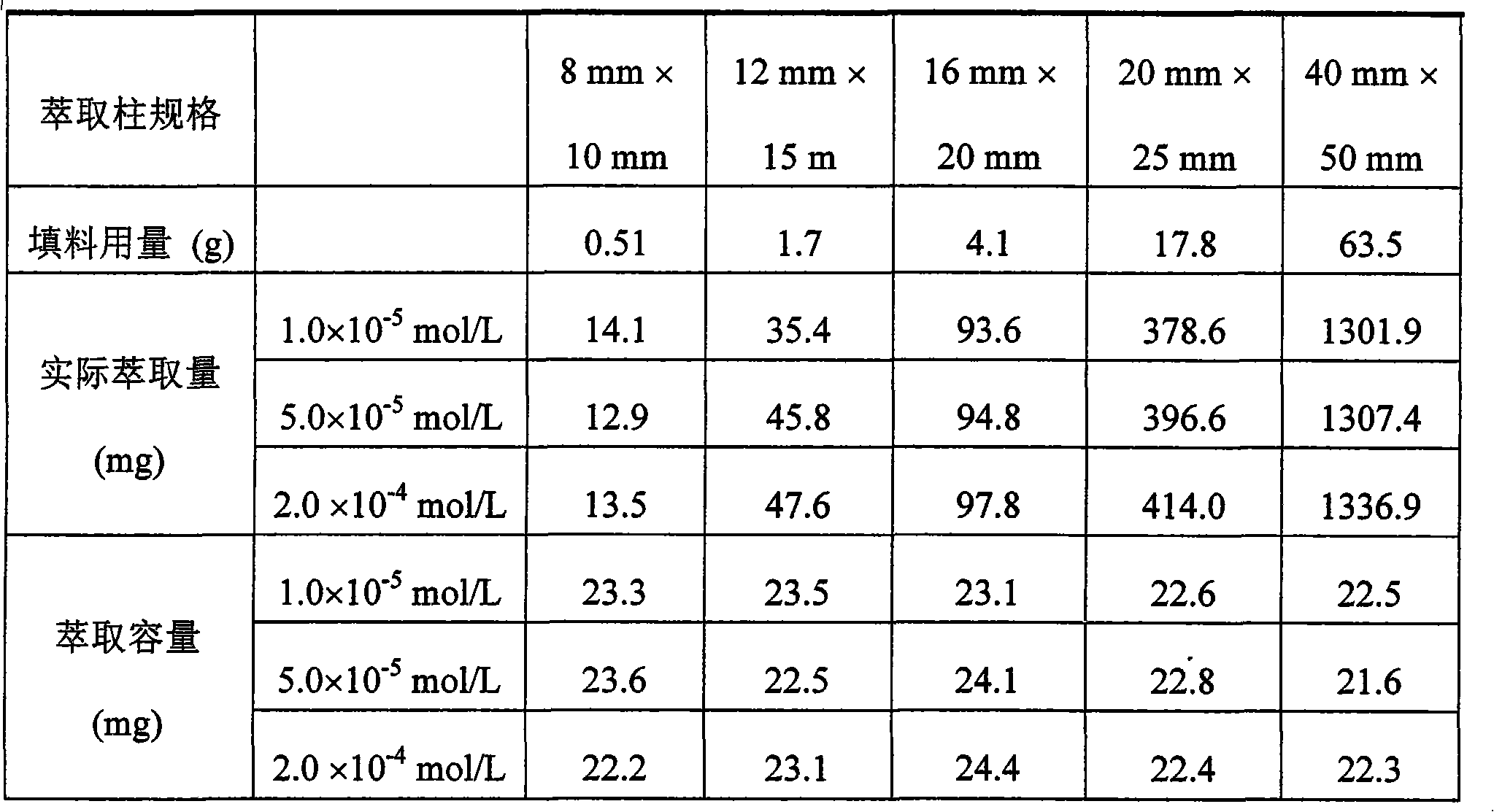

Embodiment 1

[0027] The polymer reverse-phase bonded solid-phase extraction column packing is polystyrene matrix, and the carbon atom number is C 2 、C 4 、C 8 、C 18 、C 22 Any of the alkyl groups. The solid phase extraction column has a diameter of 8 mm and a column length of 10 mm. It is first activated with ethanol, and then washed with water to remove the ethanol, which can be used for gold extraction. The preparation concentration is 1.0×10 -5 ~2.0×10 -4 KAu(CN) between mol / L 2 Solution, adjust its pH at 10.4, and add CTMAB according to the ratio of CTMAB:Au(I) molar ratio of 1:2, and this solution is used as the liquid to be extracted. When extracting, the extract is transported into the extraction column by the pump, and the volume of the extract is 2.5L to enter the saturated state. The eluent ethanol is delivered 5mL, and the activation solution ethanol is 10mL. The extraction column is eluted and activated in reverse, and then the The pump sends water to wash away the residu...

Embodiment 2

[0029] The polymer reverse-phase bonded solid-phase extraction column packing is polydivinyl phenyl, and the carbon atom number is C 2 、C 4 、C 8 、C 18 、C 22 Any of the alkyl groups. The solid phase extraction column is 16mm in diameter x 20mm in column length, and is filled with 4.1g of packing material. Activated with ethanol first, then washed with water to remove ethanol and then used for gold extraction. The preparation concentration is 2.0×10 -5 mol / L of KAu(CN) 2solution, adjust its pH at 11.8, and add CTMAB according to the ratio of CTMAB:Au(I) molar ratio of 1:1.5, and this solution is used as the liquid to be extracted. When extracting, the extract is transported into the extraction column by the pump, and the volume of the extract is 10L to enter the saturated state, and the eluent ethanol 25mL, the activation solution ethanol 25mL, the extraction column is eluted and activated in reverse, and then the pump Send water to wash off residual ethanol on the colum...

Embodiment 3

[0031] Polymer reversed-phase bonded solid-phase extraction column filler is polystyrene-divinylphenyl cross-linked polymer matrix bonded with carbon atom number C 2 、C 4 、C 8 、C 18 、C 22 Any of the alkyl groups. The solid-phase extraction column is 40mm in diameter x 50mm in column length, and packed with 63.5g of filler; it is first activated with ethanol, and then washed with water to remove the ethanol, which can be used for gold extraction. The preparation concentration is 5.0×10 -5 mol / L of KAu(CN) 2 solution, adjust its pH at 12.4, and add CTMAB according to the ratio of CTMAB:Au(I) molar ratio of 1:1.5, and this solution is used as the liquid to be extracted. When extracting, the extract is transported into the extraction column by the pump, and the volume of the extract is 40L to enter the saturated state. The eluent ethanol is transported 200mL, and the activation solution ethanol is 100mL. The extraction column is eluted and activated in reverse, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com