Artificial wetland sewage treatment system adopting rotational flow active sludge method pretreatment

A technology of sewage treatment system and activated sludge method, which is applied in the field of sewage treatment system and comprehensive sewage treatment system, can solve problems such as complex operation, achieve the effect of improving treatment conditions, improving aerobic biochemical treatment capacity, and ensuring the degree of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

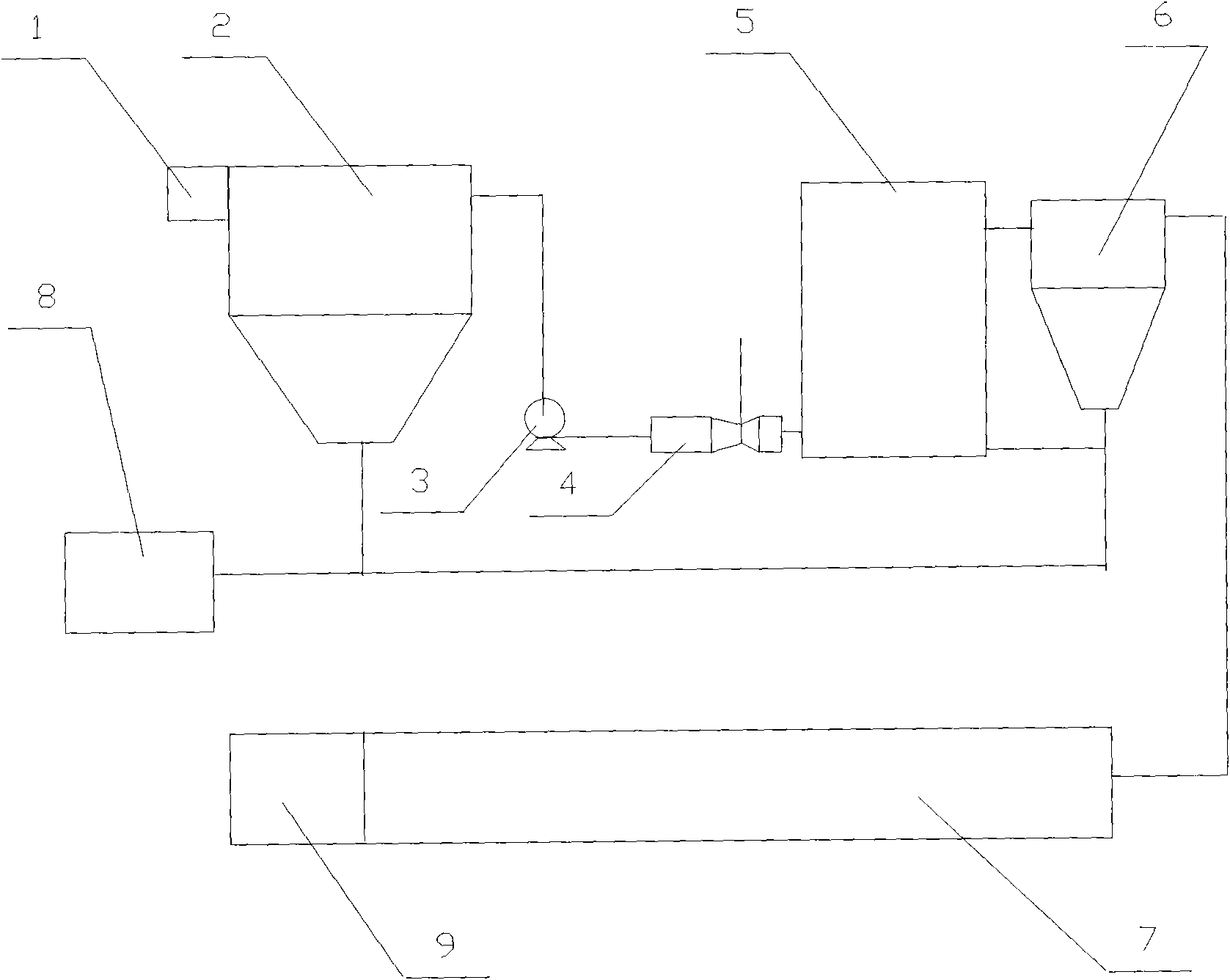

[0009] see figure 1 , the present invention provides a constructed wetland sewage treatment system that adopts the cyclone activated sludge method for pretreatment, including a primary sedimentation tank 2, a venturi tube 4, a cyclone activated sludge tank 5, a secondary sedimentation tank 6 and a constructed wetland, The grille is located in front of the first settling tank, the inlet of the tapering part of the venturi tube is connected to the upper part of the first settling tank through the high-pressure pump 3, the throat is connected to the atmosphere through the air intake pipe, and the outlet of the expanding part is provided with A jet pipe extending forward, the jet pipe is tangentially connected to the lower part of the cyclone activated sludge tank, the outlet water of the cyclone activated sludge tank is connected to the secondary sedimentation tank, and the secondary sedimentation tank The effluent is connected to the constructed wetland.

[0010] A grid can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com