Preparation method of barium strontium titanate semiconductive ceramics

A barium strontium titanate and semiconductor technology, which is applied in the field of preparation of barium strontium titanate semiconducting ceramics, can solve the problems of difficult co-firing of ceramic layers, uneven component distribution, impurity pollution, etc., and achieve good comprehensive PTCR performance, which is beneficial to Effects of layering and high lift-to-drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Y-BaTiO 3 Powder preparation steps:

[0022] Mole ratio 1mol (Ba 0.75 Sr 0.25 ) Ti 1.02 o 3 +0.4mol%Y 2 o 3 +0.04mol%Mn(NO 3 ) 2 Configure pure BaCO 3 , SrCO 3 、TiO 2 , Y 2 o 3 The powder is ball milled with distilled water for 4 hours, dried, crushed, sieved, sintered at 1200°C, and kept for 3 hours to obtain barium strontium titanate powder;

[0023] (2) Preparation steps of glass sintering aid:

[0024] 0.5mol BaCO in molar ratio 3 +1mol H 3 BO 3 +2mol% SiO 2 , weigh BaCO 3 、H 3 BO 3 , SiO 2 Powder and Mn(NO 3 ) 2 solution, with ZrO 2 Ball mill the mixture for 4 hours, dry, pulverize, and sieve, then put the mixed powder into a corundum crucible, heat it to 1100°C at a heating rate of 5°C / min, keep it warm for 60 minutes, pour it into water to quench, and get The glass frit was milled with ZrO2 balls for 4 hours, dried at 80°C, crushed and sieved to obtain glass powder;

[0025] (3) Preparation steps of PTCR ceramics

[0026] Add the gl...

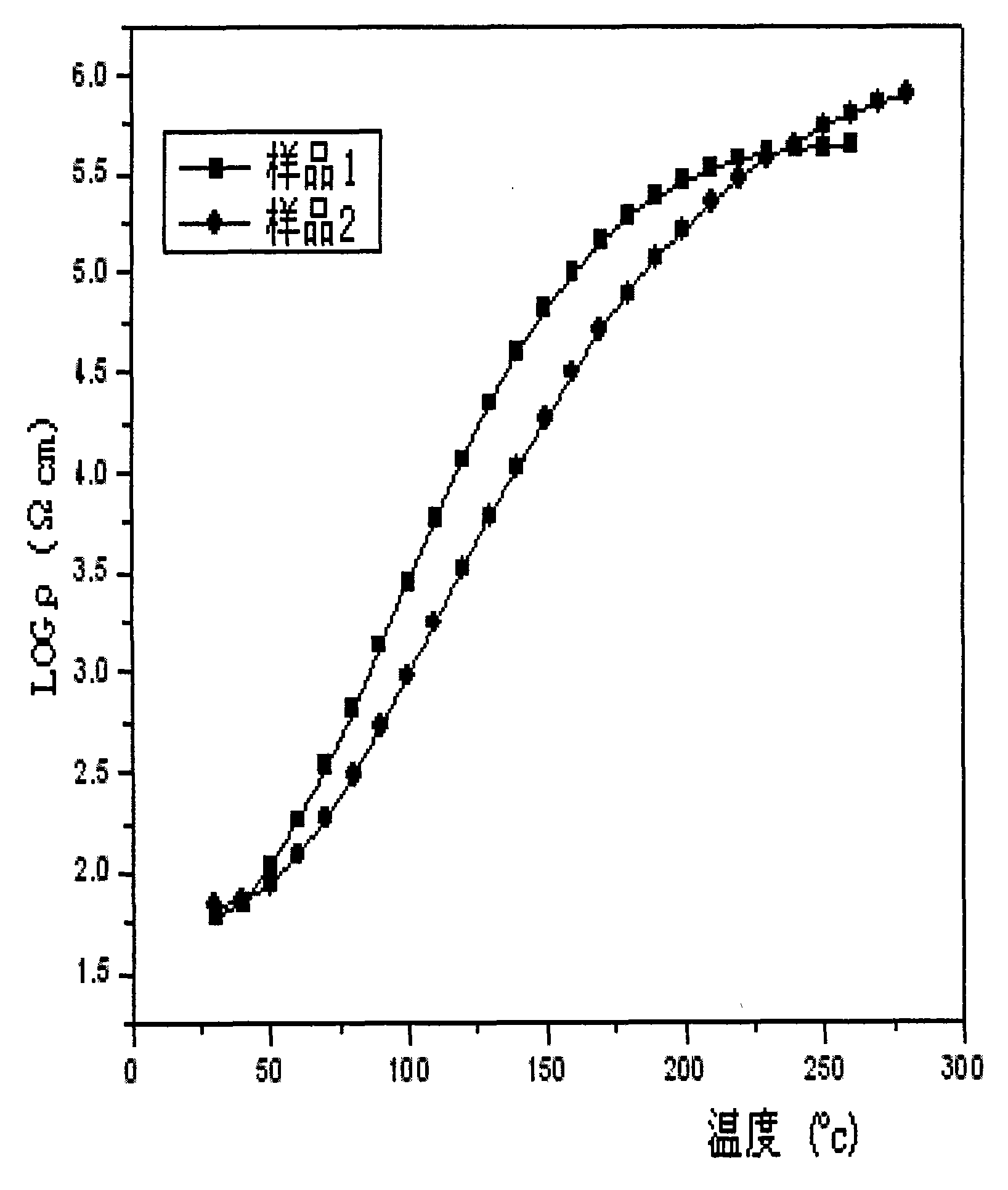

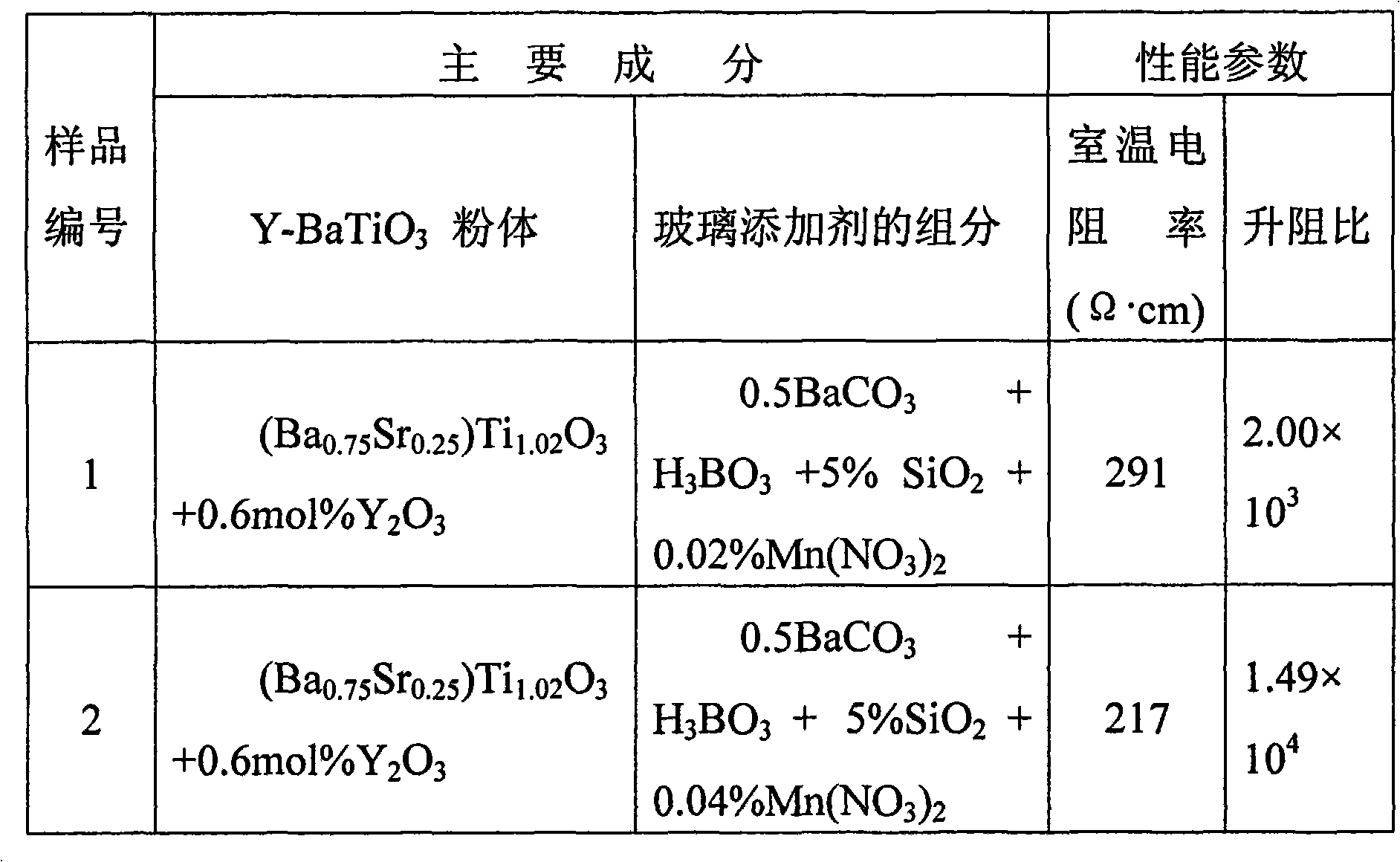

Embodiment 2

[0028] (1) Y-BaTiO 3 Powder preparation steps:

[0029] Mole ratio 1mol (Ba 0.75 Sr 0.25 ) Ti 1.02 o 3 +0.6mol%Y 2 o 3 Configuration analysis of pure BaCO 3 , SrCO 3 、TiO 2 , Y 2 o 3 The powder is ball milled with distilled water for 5 hours, dried, crushed, sieved, sintered at 1150°C, and kept for 3 hours to obtain barium strontium titanate powder;

[0030] (2) Preparation steps of glass sintering aid:

[0031] 0.5mol BaCO in molar ratio 3 +1mol H 3 BO 3 +5mol%SiO 2 +0.06mol%Mn(NO 3 ) 2 , weigh BaCO 3 、H 3 BO 3 , SiO 2 Powder and Mn(NO 3 ) 2 solution, with ZrO 2 Ball mill the mixture for 5 hours, dry, crush, and sieve, then put the mixed powder into a corundum crucible, heat it to 1150°C at a heating rate of 5°C / min, keep it warm for 30 minutes, pour it into water to quench, and get The glass frit is then ZrO 2 Ball milling for 4 hours, drying at 80°C, crushing and sieving to obtain glass powder;

[0032](3) Preparation steps of PTCR ceramics

[00...

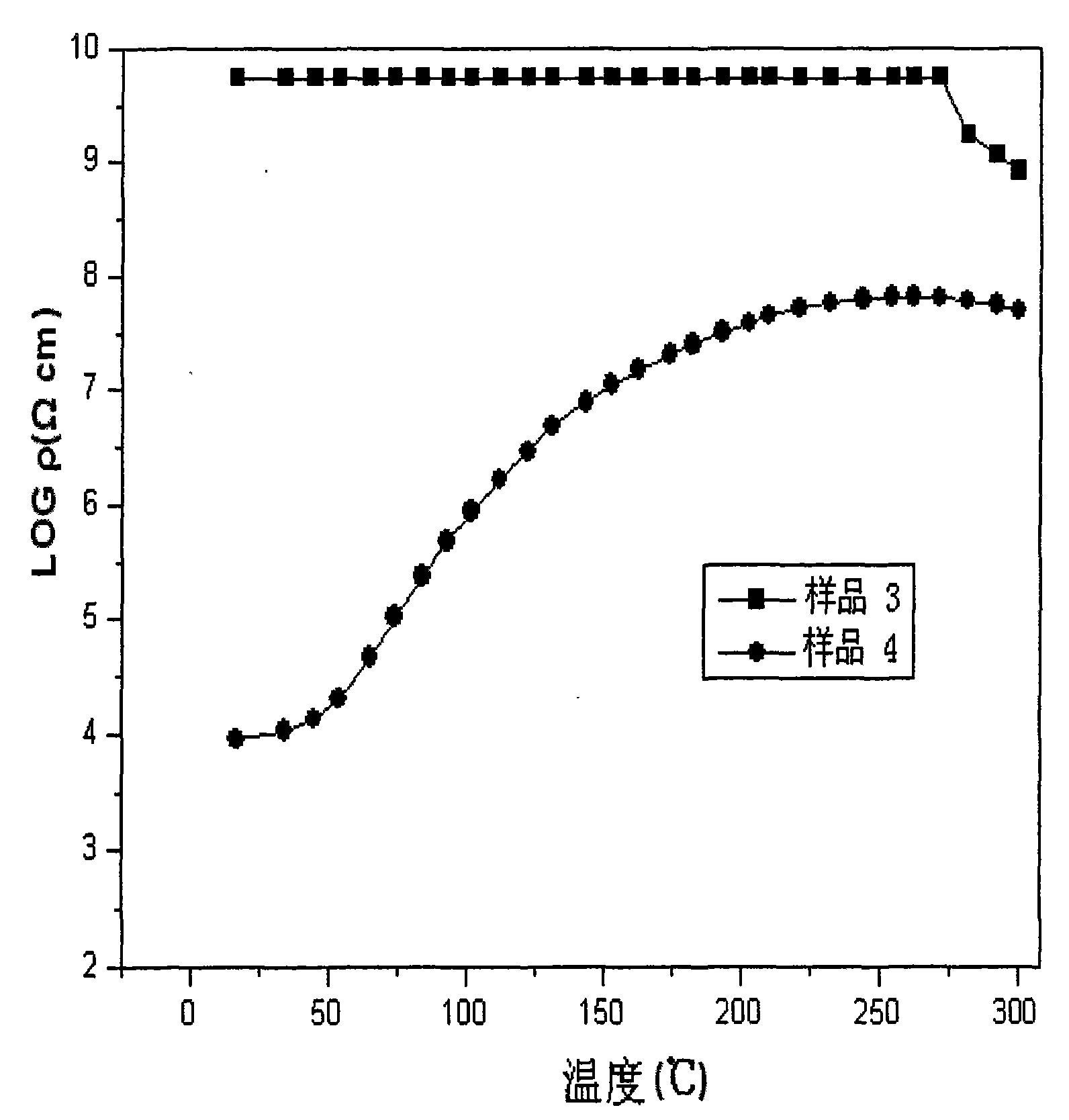

Embodiment 3

[0036] (1) Y-BaTiO 3 Powder preparation steps:

[0037] Mole ratio 1mol (Ba 0.70 Sr 0.30 ) Ti 1.01 o 3 +0.8mol%Y 2 o 3 Configuration analysis of pure BaCO 3 , SrCO 3 、TiO 2 , Y 2 o 3 The powder is ball milled with distilled water for 6 hours, dried, crushed, sieved, sintered at 1250°C, and kept for 2 hours to obtain barium strontium titanate powder;

[0038] (2) Preparation steps of glass sintering aid:

[0039] 0.5mol BaCO in molar ratio 3 +1mol H 3 BO 3 +8mol%SiO 2 , weigh BaCO 3 、H 3 BO 3 , SiO 2 Powder and Mn(NO 3 ) 2 solution, with ZrO 2 Ball mill the mixture for 6 hours, dry, pulverize, and sieve, then put the mixed powder into a corundum crucible, heat it to 1150°C at a heating rate of 5°C / min, keep it warm for 10 minutes, pour it into water to quench, and get The glass frit is then ZrO 2 Ball milling for 6 hours, drying at 100°C, crushing and sieving to obtain glass powder;

[0040] (3) Preparation steps of PTCR ceramics

[0041] Add the glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com