Method for preparing polymeric microspheres

A polymer and microsphere technology, applied in the field of polymer synthesis and technical processing, can solve the problem of high production cost, achieve the effects of low energy consumption, suitable for large-scale preparation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, preparation polymer microsphere

[0016] Use a 1.7MHz ultrasonic atomizing humidifier to atomize the secondary water into water droplets with a diameter of less than 5um, and use a catheter to guide the atomized airflow (flow rate of 1m / s) to the ethyl 2-cyanoacrylate spread on the glass surface On the surface of the liquid film, OH- in water initiates a polymerization reaction. After a few seconds, the liquid film appears white. After one minute, the reaction is complete. Remove the atomized water flow and dry at room temperature.

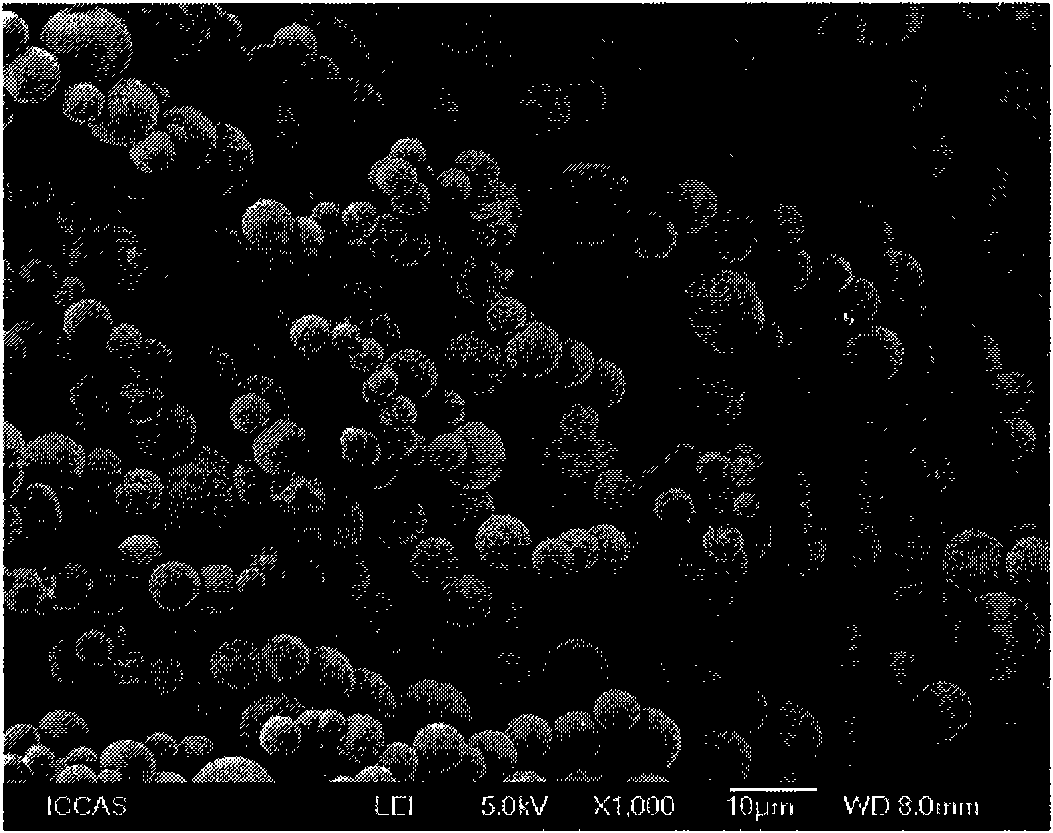

[0017] Observed under the electron microscope, there are polymer beads with a diameter of 1-10 microns, such as figure 1 shown.

Embodiment 2

[0018] Embodiment 2, preparation polymer microsphere

[0019] Use a 1.7MHz ultrasonic atomizing humidifier to atomize the secondary water into micro-water droplets with a diameter of less than 5um, and use a catheter to guide the atomized airflow (flow rate of 5m / s) to the 2-cyanoacrylic acid n-butylene spread on the glass surface On the surface of the ester liquid film, OH- in water initiates a polymerization reaction, and the liquid film appears white after a few seconds, and the reaction is complete after one minute, remove the atomized water flow, and dry at room temperature.

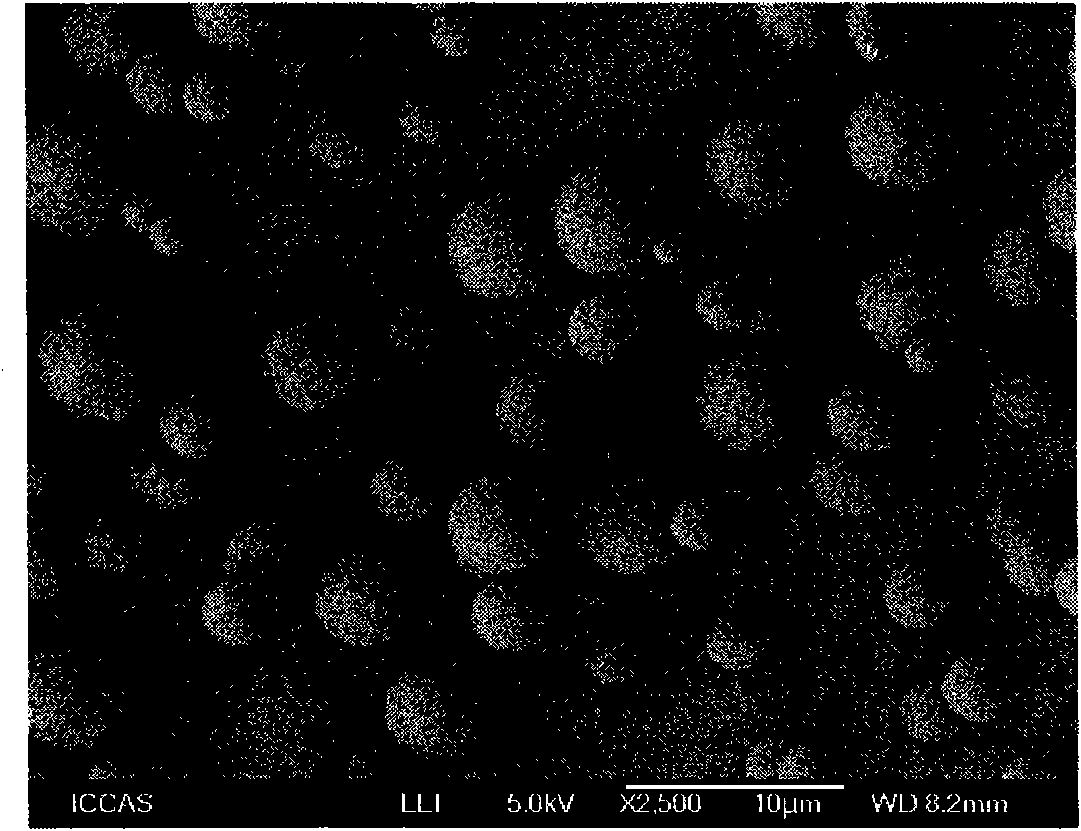

[0020] Observed under the electron microscope, there are polymer beads with a diameter of 1-10 microns, such as figure 2 shown.

Embodiment 3

[0021] Embodiment 3, preparation polymer microsphere

[0022] Use a 1.7MHz ultrasonic atomizing humidifier to atomize the secondary water into droplets with a diameter of less than 5um, and use a catheter to guide the atomized airflow (flow rate of 5m / s) to the isobutyl cyanoacrylate spread on the glass surface On the surface of the ester liquid film, OH- in water initiates a polymerization reaction, and the liquid film appears white after a few seconds, and the reaction is complete after one minute, remove the atomized water flow, and dry at room temperature.

[0023] Observed under an electron microscope, there are polymer balls with a diameter of 1-10 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com