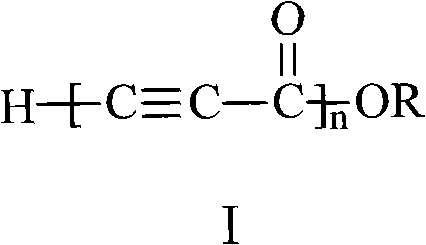

Alkynyl-containing conjugated polymers and synthetic method thereof

A technology of conjugated polymers and synthetic methods, applied in the field of alkyne-containing conjugated polymers and their synthesis, can solve the problems of low reaction yield, low monomer conversion rate, wide product molecular weight distribution, etc., and achieve solubility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

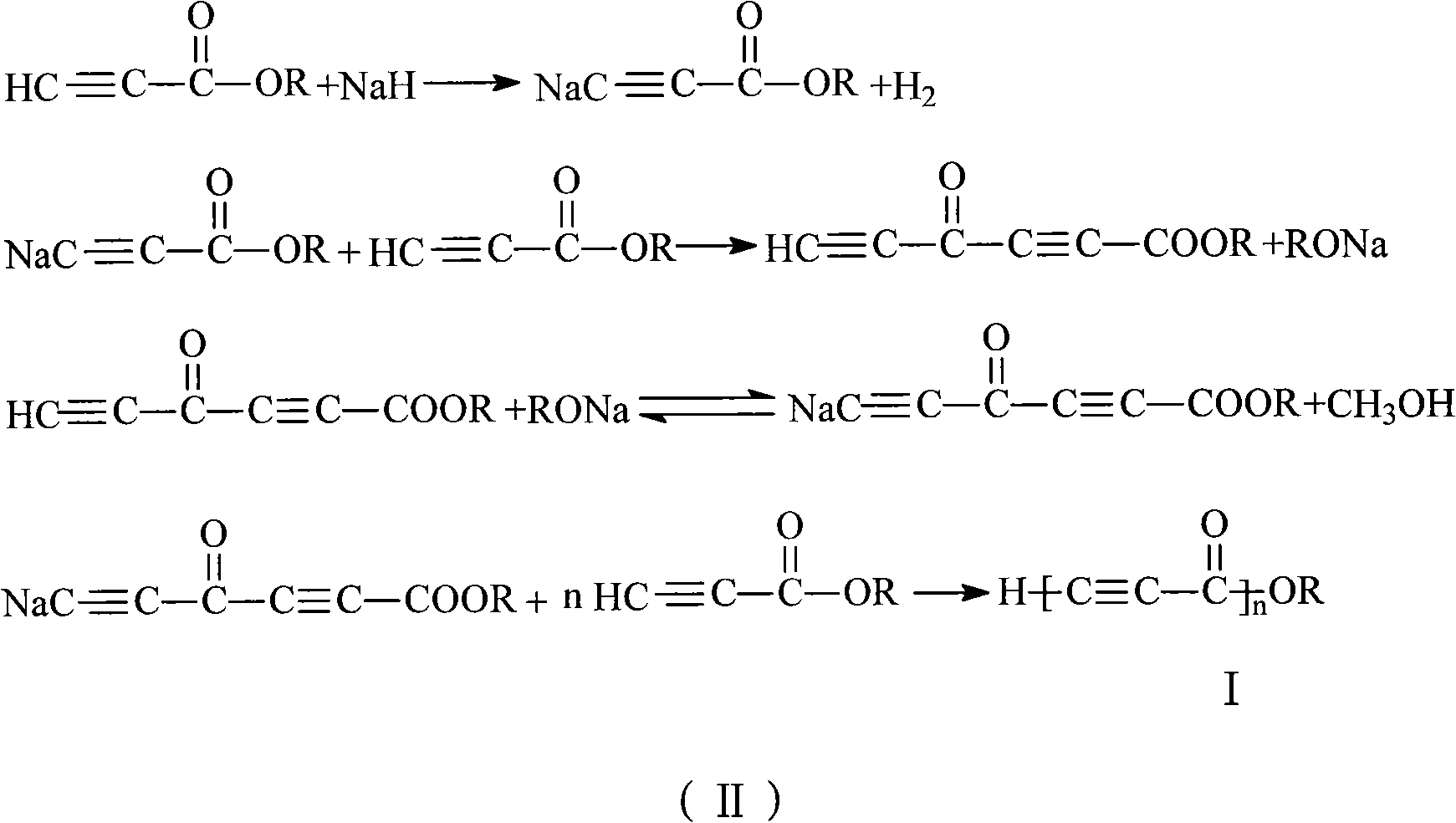

Method used

Image

Examples

Embodiment 1

[0023] Add 1ml of monomeric methyl propiolate into the two horn tubes with a 1ml syringe, then put the two horn tubes into the atmosphere at -20°C, and add 139.5 mg of initiator sodium hydride (the ratio of the amount of the monomer to the initiator substance 2:1), reacted for 24 hours to obtain a black solid; washed the black solid with dilute hydrochloric acid with a mass concentration of 25% for 0.5 hours, separated to obtain a solid product, and dried it in a vacuum oven at 50°C to obtain a conjugated compound containing an alkyne group polymer. The conversion rate of monomer was 44.3%.

Embodiment 2

[0025] Add 1ml of monomeric methyl propiolate into the two horn tubes with a 1ml syringe, then put the two horn tubes into the atmosphere at -20°C, and add 2.8 mg of initiator sodium hydride (the ratio of the amount of the monomer to the initiator substance 100:1), reacted for 24 hours to obtain a black solid; the black solid was washed with dilute hydrochloric acid with a mass concentration of 25% for 0.5 hours, and the solid product was isolated, and dried in a vacuum oven at 50°C to obtain a conjugated alkyne group polymer. The conversion rate of monomer was 39.2%.

Embodiment 3

[0027] Add 1ml of monomeric methyl propiolate into two mouths of horn tubes with a 1ml syringe, then put the two mouths of horn tubes into an atmosphere of 30°C, and add 9.3 mg of initiator sodium hydride (the molar ratio of the monomer and the initiator substance is 30:1), reacted for 6 hours to obtain a black solid; washed the black solid with dilute hydrochloric acid with a mass concentration of 25% for 0.5 hours, separated to obtain a solid product, and dried it in a vacuum oven at 50°C to obtain things. The conversion rate of monomer was 78.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com