Resin composition, resin-coated copper foil produced by same and copper-clad plate produced by utilizing resin-coated copper foil

A resin composition and resin coating technology, applied in the direction of improving the metal adhesion of insulating substrates, layered products, metal layered products, etc., can solve the problems of large thickness of prepreg, exposed cloth lines, and difficulties in producing thin copper clad laminates, etc. problem, to achieve the effect of good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

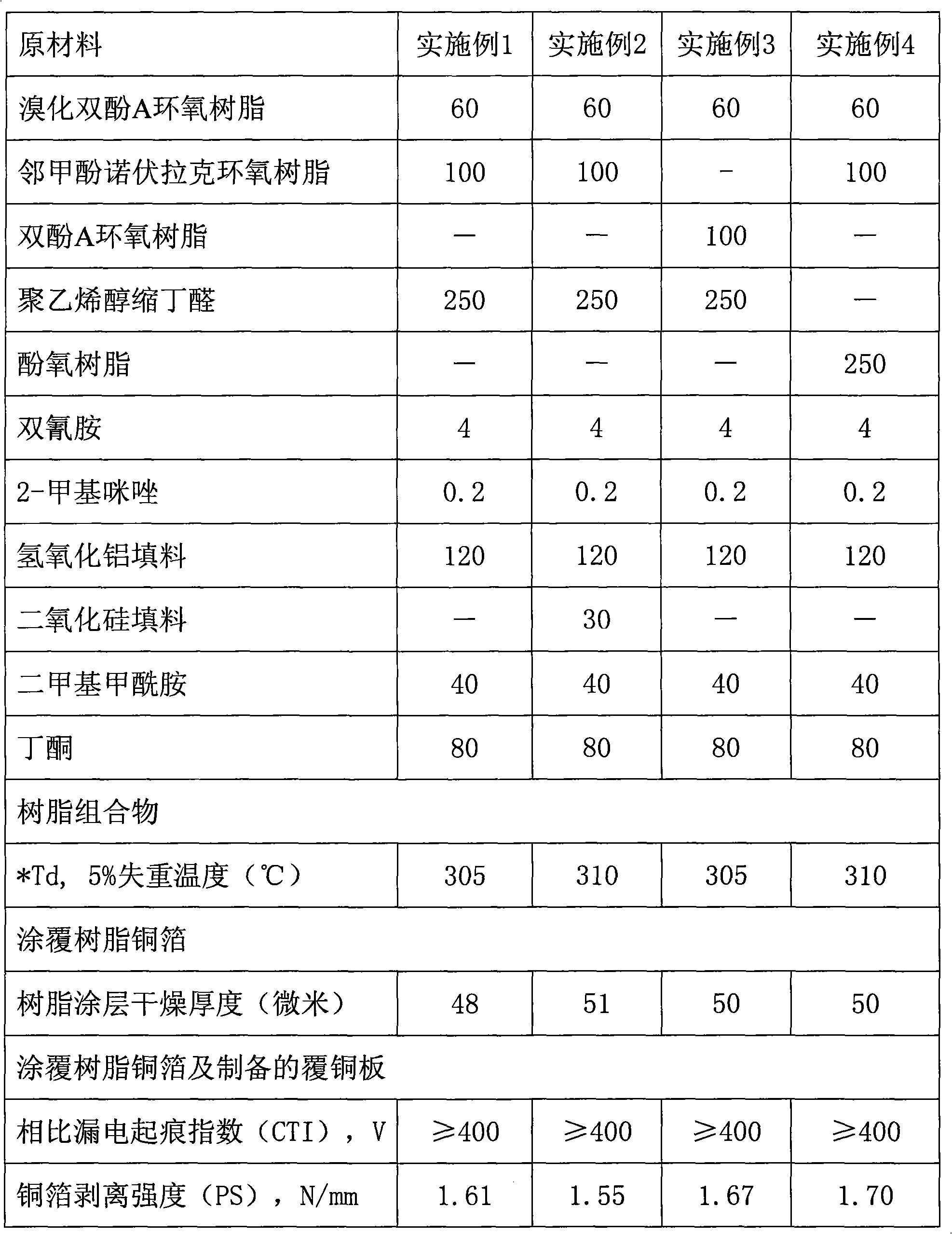

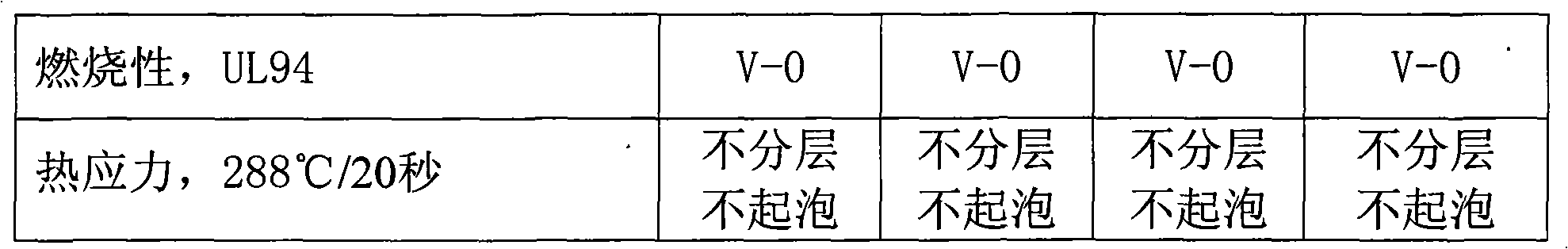

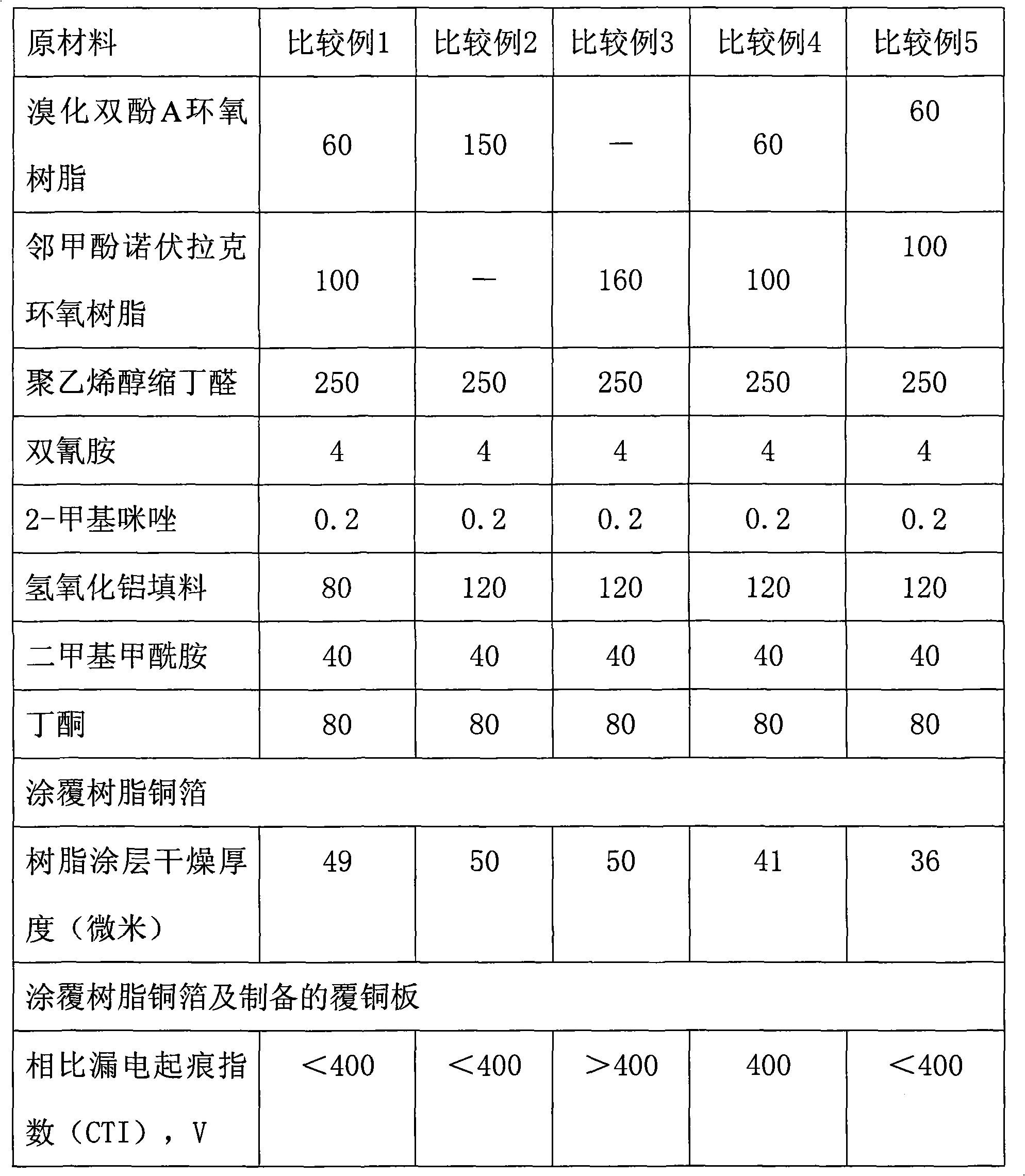

Embodiment 1

[0046] (1) Preparation of resin composition

[0047]Add 4 grams of dicyandiamide (DICY) to a clean and dry 750 ml beaker equipped with a stirrer, then add 40 grams of dimethylformamide (DMF) solvent, stir for 10 minutes to completely dissolve DICY, then add 0.200 grams of 2 -Methylimidazole, after dissolving completely, then add 80 grams of methyl ethyl ketone (MEK) to the solution, and stir and mix for 20 minutes. Then start to add 120 grams of aluminum hydroxide (the product of Martin Company in Germany, the trade name is OL-104WE) to the solution, add while stirring, slowly add all the aluminum hydroxide gradually in 2 to 3 minutes, and avoid oxidizing all the hydroxide. Pour the aluminum into the beaker at one time; after adding the aluminum hydroxide, stir and mix at high speed for 30 minutes to disperse the filler evenly. Under the condition of keeping stirring, add 60 grams of brominated bisphenol A epoxy resin (Huntsman company product, brand name Aroldite LZ8008 A80)...

Embodiment 2

[0053] (1) Preparation of resin composition

[0054] Add 4 grams of dicyandiamide (DICY) to a clean and dry 750 ml beaker equipped with a stirrer, then add 40 grams of dimethylformamide (DMF) solvent, stir for 10 minutes to completely dissolve DICY, then add 0.200 grams of 2 -Methylimidazole, after dissolving completely, then add 80 grams of methyl ethyl ketone (MEK) to the solution, and stir and mix for 20 minutes. Then start to add 120 grams of aluminum hydroxide (the product of Martin Company in Germany, the trade name is OL-104WE) to the solution, add while stirring, slowly add all the aluminum hydroxide gradually in 2 to 3 minutes, and avoid oxidizing all the hydroxide. Pour the aluminum into the beaker at one time; after adding the aluminum hydroxide, stir and mix at high speed for 30 minutes to disperse the filler evenly. While keeping stirring, continue to add 30 grams of silicon micropowder (Zhengzhou Jinyuan Micropowder Material Co., Ltd., brand JYEG-11), and stir e...

Embodiment 3

[0058] (1) Preparation of resin composition

[0059] Add 4 grams of dicyandiamide (DICY) to a clean and dry 750 ml beaker equipped with a stirrer, then add 40 grams of dimethylformamide (DMF) solvent, stir for 10 minutes to completely dissolve DICY, then add 0.200 grams of 2 -Methylimidazole, after dissolving completely, then add 80 grams of methyl ethyl ketone (MEK) to the solution, and stir and mix for 20 minutes. Then start to add 120 grams of aluminum hydroxide (the product of Martin Company in Germany, the trade name is OL-104WE) to the solution, add while stirring, slowly add all the aluminum hydroxide gradually in 2 to 3 minutes, and avoid oxidizing all the hydroxide. Pour the aluminum into the beaker at one time; after adding the aluminum hydroxide, stir and mix at high speed for 30 minutes to disperse the filler evenly. Then, add 60 gram of brominated bisphenol A epoxy resins (Huntsman company product, brand name ArolditeLZ8008 A80), 100 gram of bisphenol A type epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com