Method and device for preventing thallus in fermentation tank from adhering

A fermenter and bacteria technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc., to achieve the effect of improving fermentation efficiency, convenient operation and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

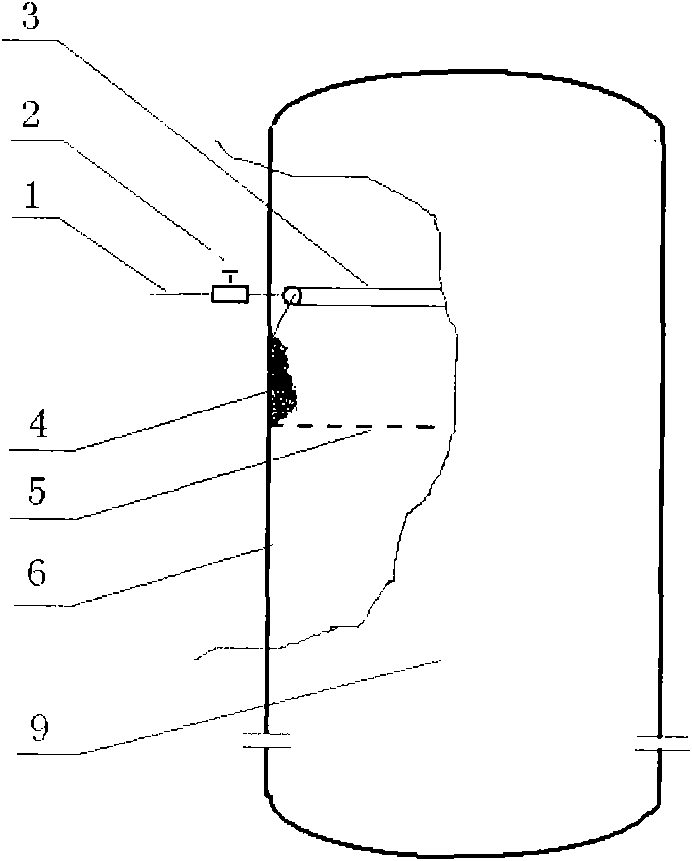

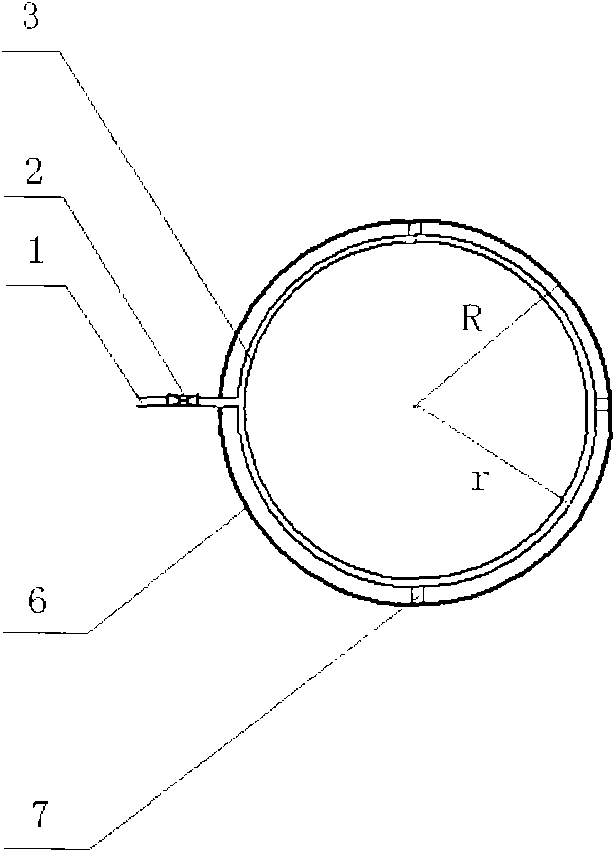

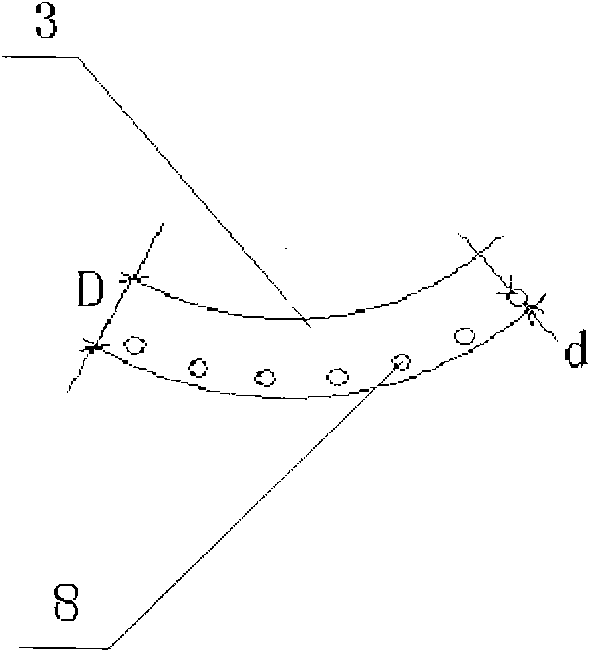

[0030] according to Figure 1-3 As shown, the device of the present invention for implementing the method for preventing the adherence of bacterial cells in the fermentor includes a pipeline 1, a flow regulating valve 2 and a ring device 3, and the ring device 3 is fixed in the fermentor 9 through a positioning bracket 7. The annular device 3 is provided with injection holes 8.

[0031] In the process of fermenting Sorangium cellulosum ATCC 15384 to produce epothilone in a fermenter, the adhesion of the bacteria to the wall is serious. The method and device of the present invention relieve the adhesion of the bacteria. For the wall adhesion problem, the relevant parameters of the invention device are as follows:

[0032] The total volume of the fermentation tank V: 500 liters; liquid filling factor λ: 75%

[0033] The inner radius of the fermentation tank R: 290mm; the bending radius of the ring tube: 270mm

[0034] Number of injection holes opening N: 100; injection hole diameter ...

Embodiment 2

[0047] In the process of fermenting Aspergillus terreus ATCC 20542 to produce lovastatin, the adhesion of the bacteria to the wall is serious. The method and device of the present invention relieve the adhesion of the bacteria to the wall. For adhesion issues, the relevant parameters of the invention device are as follows:

[0048] The total volume of the fermentation tank V: 50 liters; liquid filling factor λ: 70%

[0049] The inner radius of the fermentation tank R: 150mm; the bending radius of the ring tube r: 130mm

[0050] Number of injection holes opening N: 60; injection hole diameter d: 1mm

[0051] Annular tube opening area A: 47.1mm 2 ; Annular tube diameter D: 8mm

[0052] Fluid type: sterile liquid; diameter of sterile air delivery pipe Φ: 15mm

[0053] Aseptic air pressure P: 0.2MPa; pressure in the fermentation tank p: 0.03MPa

[0054] The distance between the annular device and the fermentation liquid surface T: 30mm; the angle between the spray direction and the inne...

Embodiment 3

[0063] In the process of fermenting Sorangium cellulosum ATCC 15384 to produce epothilone in a fermenter, the adhesion of the bacteria to the wall is serious. The method and device of the present invention relieve the adhesion of the bacteria. For the wall adhesion problem, the relevant parameters of the invention device are as follows:

[0064] The total volume of the fermentation tank V: 500 liters; liquid filling factor λ: 75%

[0065] The inner radius of the fermentation tank R: 290mm; the bending radius of the ring tube: 270mm

[0066] Number of injection holes opening N: 40; injection hole diameter d: 0.2mm

[0067] Ring tube opening area A: 1.26mm 2 ; Annular tube diameter D: 6mm

[0068] Fluid type: sterile air; diameter of sterile air delivery pipe Φ: 20mm

[0069] Aseptic air pressure P: 0.15MPa; Pressure in the fermentation tank p: 0.03MPa

[0070] The distance between the ring device and the fermentation liquid surface T: 55mm; the angle between the spray direction and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com