Method for preparing ethanol from yam raw materials

A potato and raw material technology, which is applied in the field of ethanol preparation, can solve the problems of wastewater not meeting environmental requirements, high pressure of wastewater treatment, and low ethanol yield, and achieve the effects of increasing yield, reducing COD value, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0069] (1) Peeling and crushing of cassava raw materials

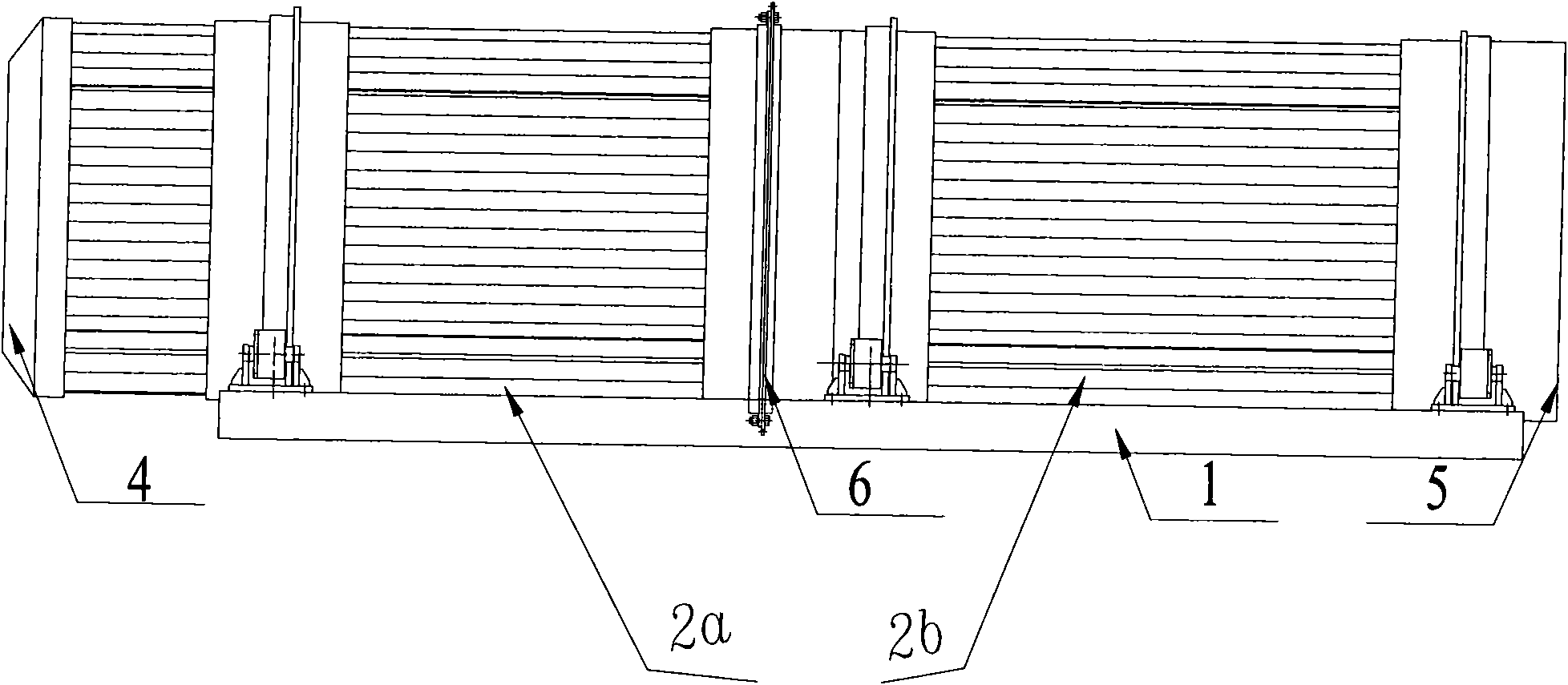

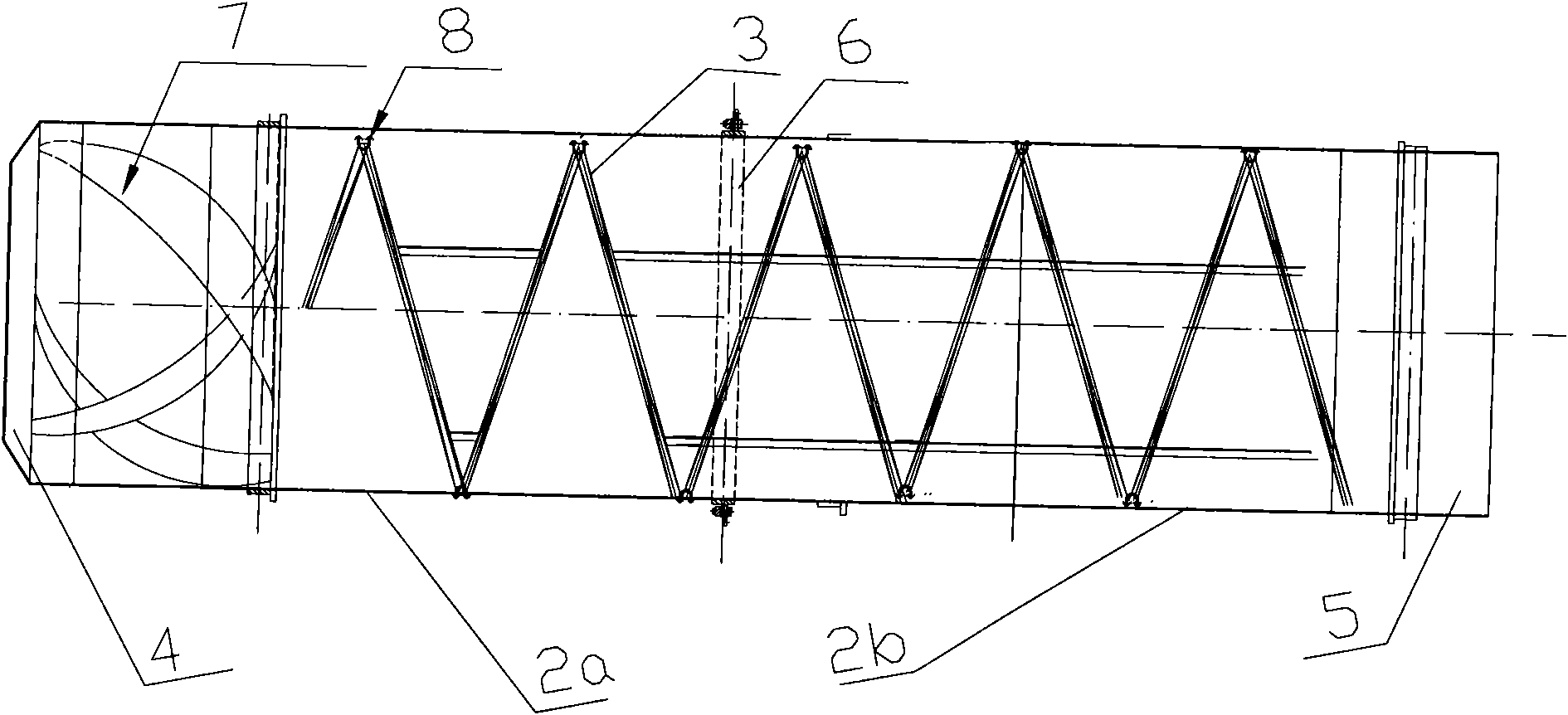

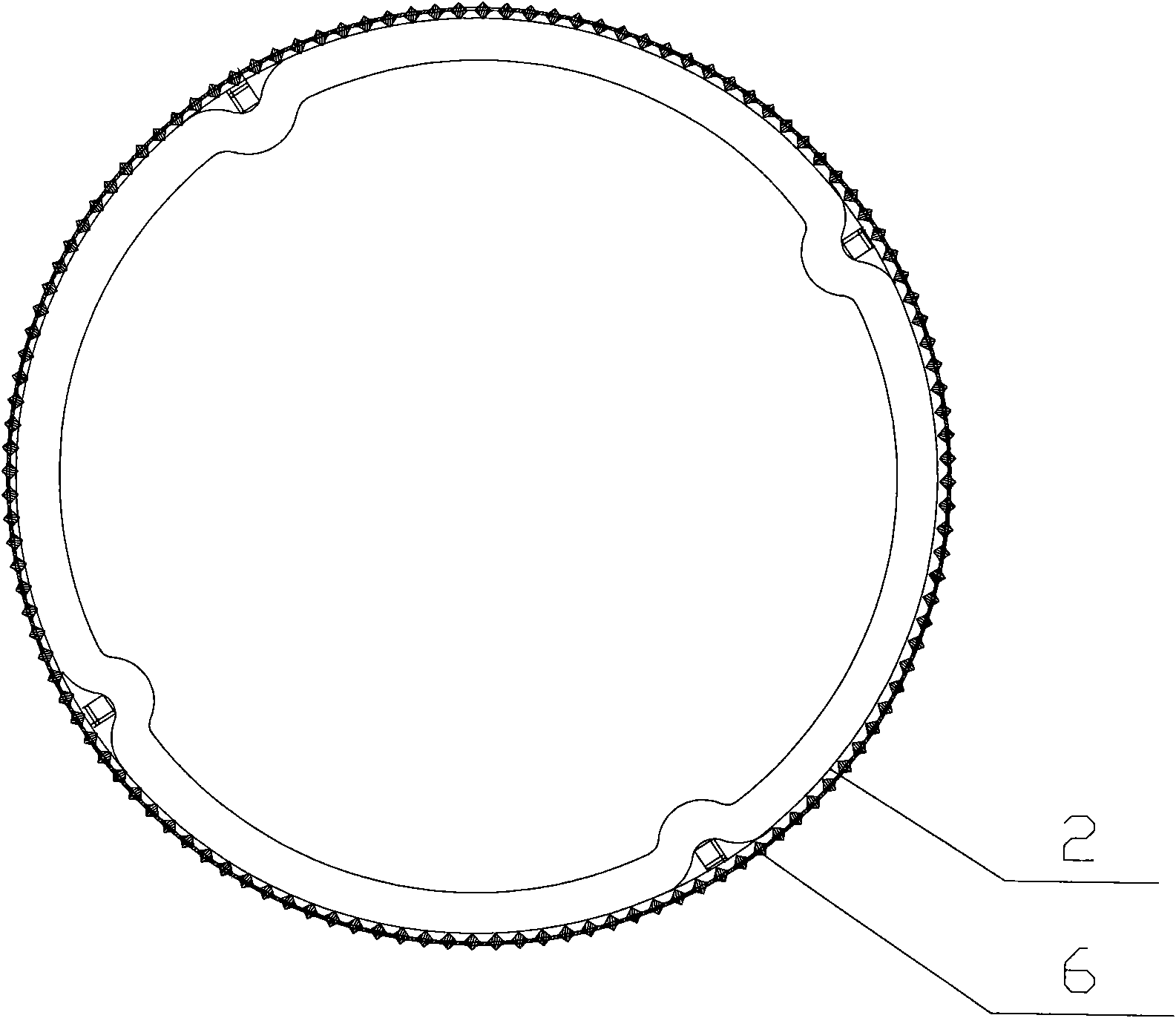

[0070] Prepared as follows figure 1 , 2 and the peeling device shown in 3.

[0071] The drum 2 includes a first segment drum 2a and a second segment drum 2b from top to bottom, the first segment drum 2a and the second segment drum 2b are connected, and the lengths of the first segment drum 2a and the second segment drum 2b are respectively 1.8 meters and 1.6 meters; the drum 2 is made of steel with an inner diameter of 1.6 meters; 40 hot-rolled ribbed steel bars with a length of 1.5 meters are fixed on the inner wall of the first section drum 2a (the brand is HRB335, and the nominal diameter is 12 mm ), each hot-rolled ribbed steel bar is parallel to the central axis of the drum, each hot-rolled ribbed steel bar is distributed at equal intervals along the circumference of the inner wall o...

Embodiment 2

[0097] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0098] Prepare ethanol according to the method for Example 1, the difference is that in step (4), 5 tons of waste liquid with a water content of 93.5% by weight is added to a membrane filter press (Jingjin Filter Press Group Co., Ltd., X M A ZG600 / 1500×2000U B K ) to filter, the number of common filter plates in the diaphragm filter press is 60, the number of diaphragm filter plates is 60, and the common filter plates are arranged at intervals with the diaphragm filter plates; the conditions of the filtration include the pressure of filtration is 0.4 MPa, and the time of filtration is 8 hours to obtain a filter cake; fill the squeeze medium air in the diaphragm filter plate, and squeeze the filtered filter cake, the pressure of the squeeze is 25 MPa, and the time of squeezing is 25 MPa. After 0.2 hours, waste water A2 after solid-liquid separatio...

Embodiment 3

[0113] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0114] Prepare ethanol according to the method for embodiment 1, difference is, when adopting the peeling equipment of embodiment 1 to carry out peeling, after starting motor, make cylinder 2 and screw feeder 3 rotate around the central axis of cylinder (rotating speed is 12 rev / min); 100 kilograms of fresh cassava (thick 4-8 centimeters, long 20-30 centimeters, water content 65 weight %) that harvested 100 kilograms of surface cleanings are continuously added in the drum 2 through the feed port 4, and the cassava is in the drum Discharge from discharge port 5 after staying on average for 1.2 minutes, and collect and obtain 96.5 kilograms of peeled cassava raw materials.

[0115] The pulverized method comprises mixing 96.5 kilograms of peeled cassava chips with 48.5 kilograms of water, and using the SFSP series hammer mill to pulverize the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap