Protection device for automatic ignition and brennschluss of commercial gas furnace

A technology for automatic ignition and flameout protection, applied in household stoves/stoves, applications, household cooking utensils, etc., can solve problems such as high maintenance costs, shortened thermocouple life, inconvenience, etc., to improve the level of automatic operation and reduce power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

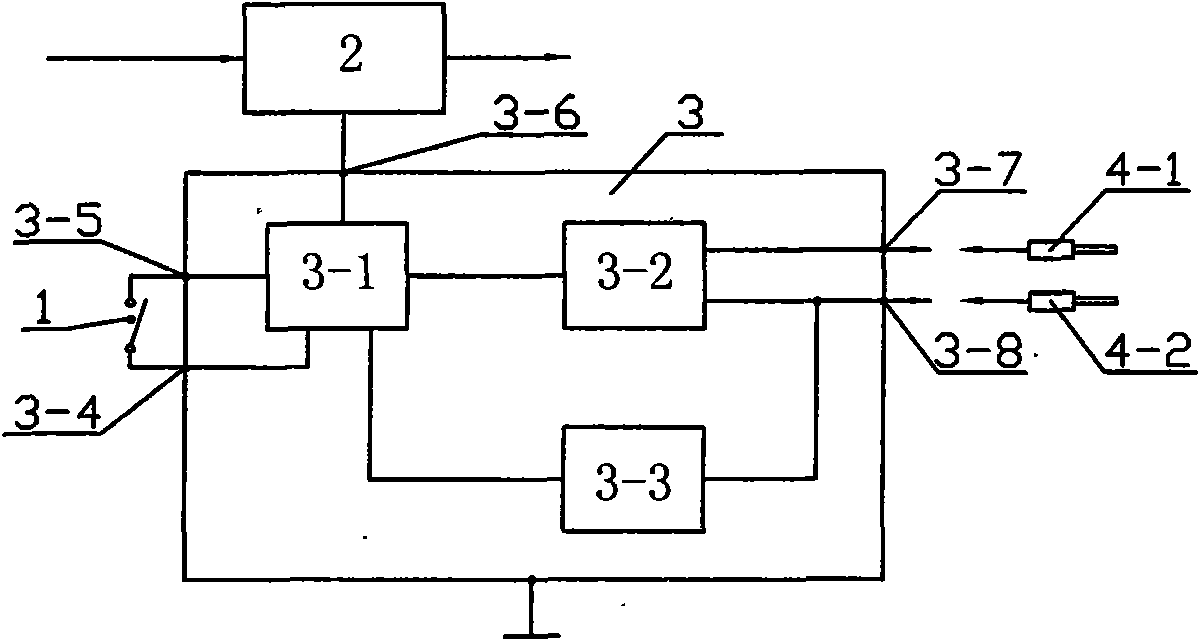

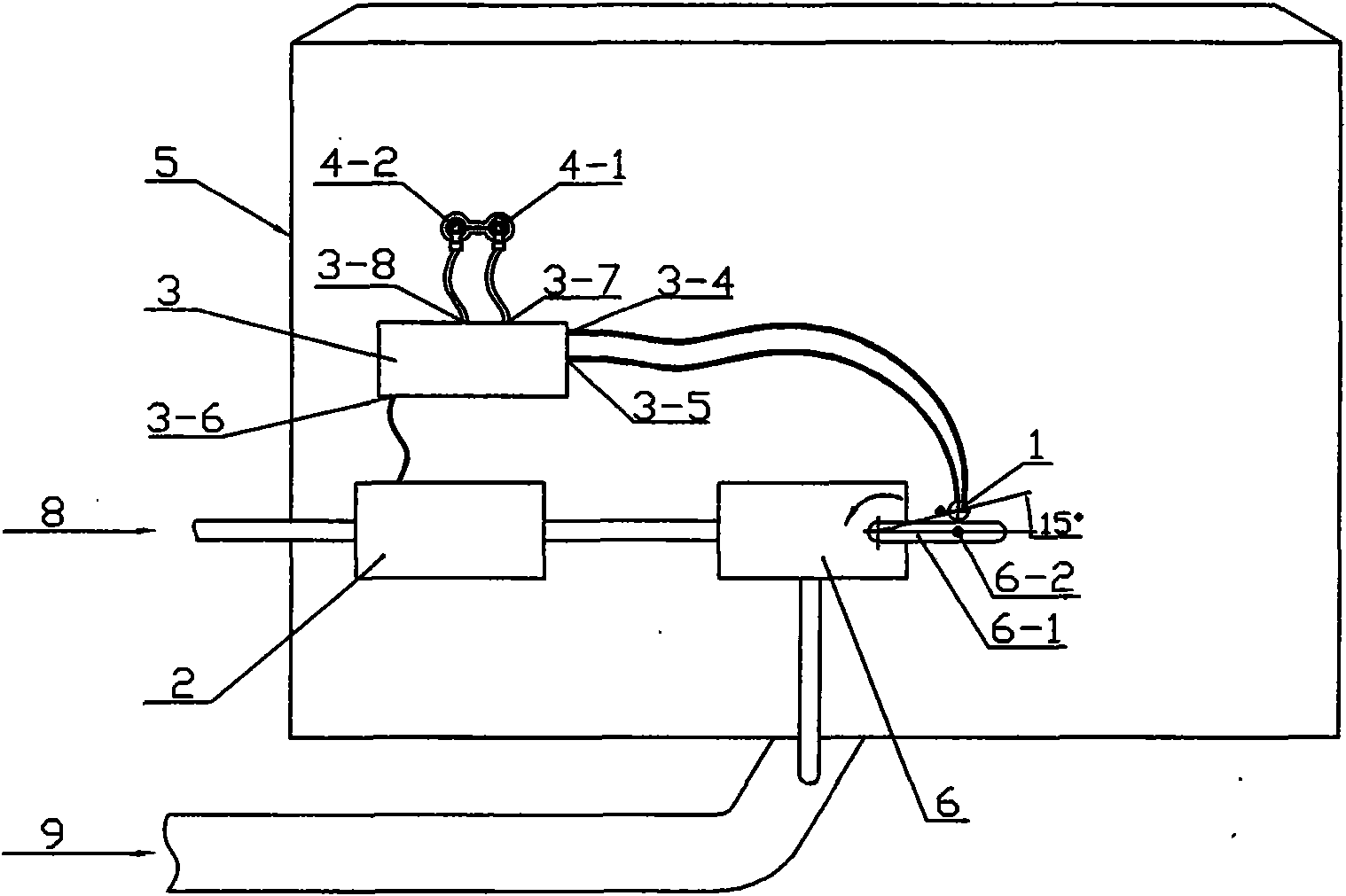

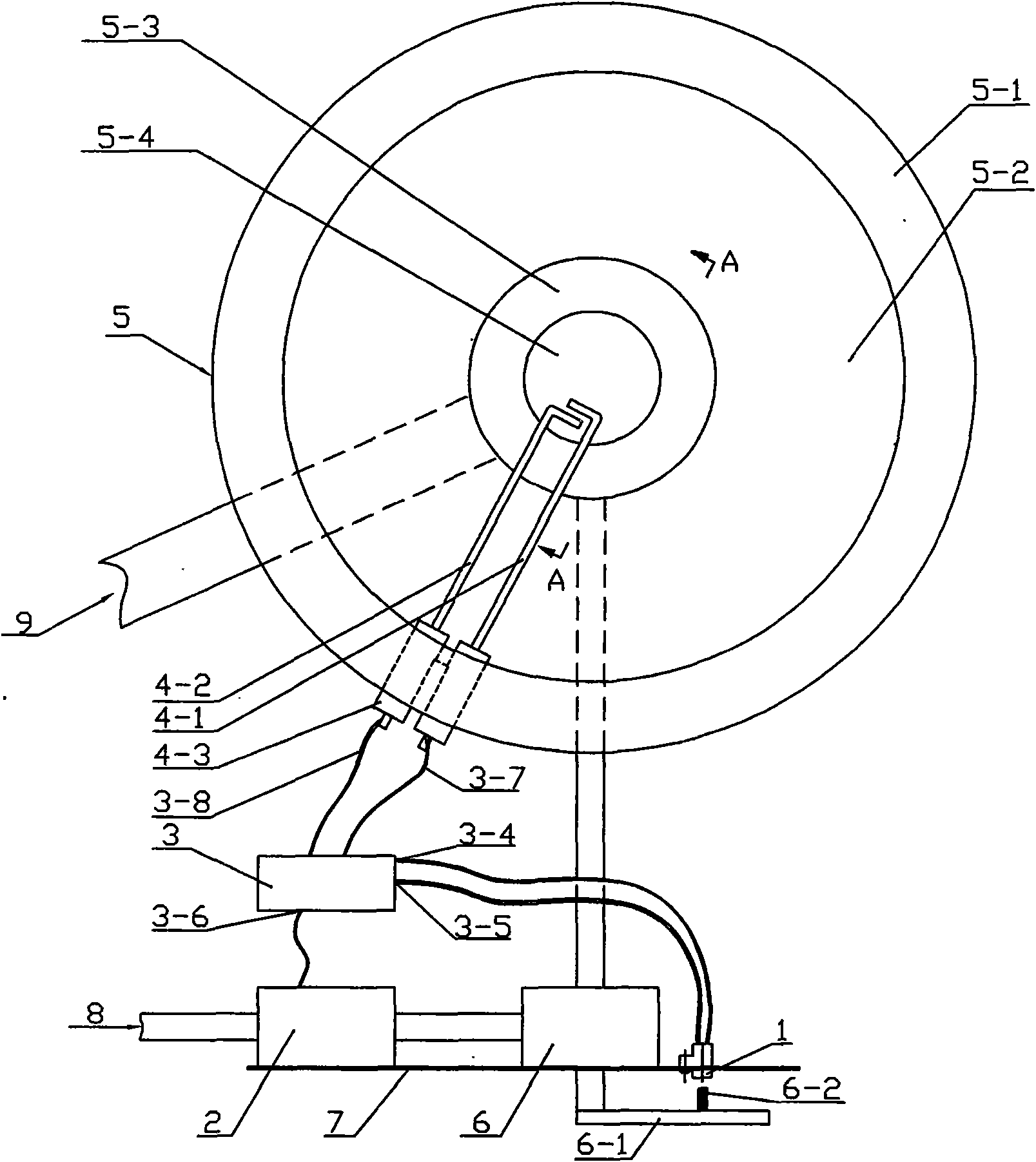

[0026] see figure 1 , figure 2 , image 3 , Figure 4 As shown, in the automatic ignition and flameout protection device for a commercial gas furnace according to an embodiment of the present invention, the commercial gas furnace includes an operation panel 7, a manual gas regulating valve 6, a burner 5-3, a furnace body 5, a refractory layer 5-1, Furnace 5-2, fire channel 5-4, commercial gas furnace automatic ignition and flameout protection device includes switch 1, gas solenoid valve 2, controller 3, the controller 3 includes main controller 3-1, continuous high-frequency high-voltage Igniter 3-2, flame ion detector 3-3, switch interface 3-4, 3-5, ignition and flame detection interface 3-7, 3-8, gas solenoid valve interface 3-6, two ignition rods 4 -1, 4-2 and the ceramic insulator 4-3 for fixing and electrical insulation at the root, the main controller 3-1 in the controller 3 is respectively connected with the continuous high-frequency high-voltage igniter 3-2 and the...

Embodiment 2

[0029] This embodiment is based on the embodiment 1, and the gas solenoid valve 2 and the controller 3 are assembled into a whole. In this embodiment, the gas solenoid valve 2 is a gas flow regulating valve. When ignited, the gas flow regulating valve 2 adjusts the gas flow by controlling the coil current to change the opening of the valve opening. The opening of the gas flow regulating valve 2 is controlled Its gas flow is about 50%-80% of the maximum value. The gas mixture is passed through the refractory layer 5-1, the furnace 5-2 and the burner 5-3 in the fire channel 5-4 of the burner 5-3 and then extends into the ignition rod 4- in the fire channel 5-4. 1, 4-2 The ionized flame generated by the metal tip is ignited. After the flame ion detector 3-3 in the controller 3 detects the ion current sent back by the ignition rod 4-2, the current provided by the main controller 3-1 makes the valve opening of the gas flow regulating valve 2 open to At the maximum, the handle 6-1...

Embodiment 3

[0031] This embodiment is a specific implementation in which the ignition rods 4-1, 4-2 are extended from the bottom of the burner 5-3 into the fire channel 5-4.

[0032] see Figure 5 As shown, the ignition rods 4-1, 4-2 pass through the inner wall of the bottom of the burner 5-3 through the ceramic insulator 4-3 and are fixed, and the ignition rods 4-1, 4-2 are about 20mm away from the tip end of the metal body They are respectively bent into 90°, and the gap between the extreme ends is 4-6mm, and they are located in the fire path 5-4.

[0033] Except for the above, the rest of this embodiment is the same as Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com