Component analyzer for laser probe micro-area

A component analysis, laser probe technology, applied in material excitation analysis, material analysis by optical means, material analysis, etc., can solve the problem of inability to complete the component analysis, analysis, and neglect of large-size samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in more detail below by means of examples, but the following examples are only illustrative, and the protection scope of the present invention is not limited by these examples.

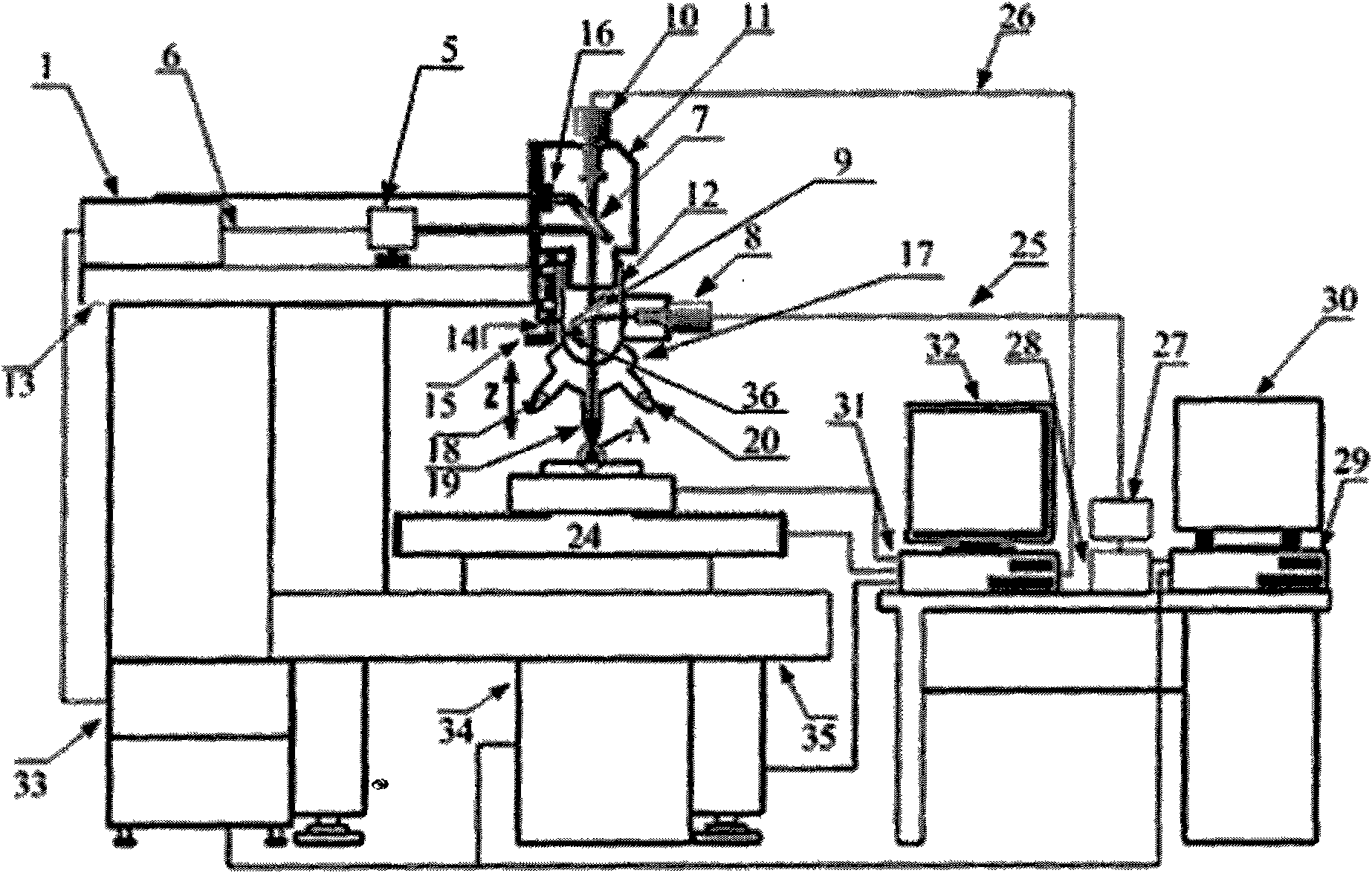

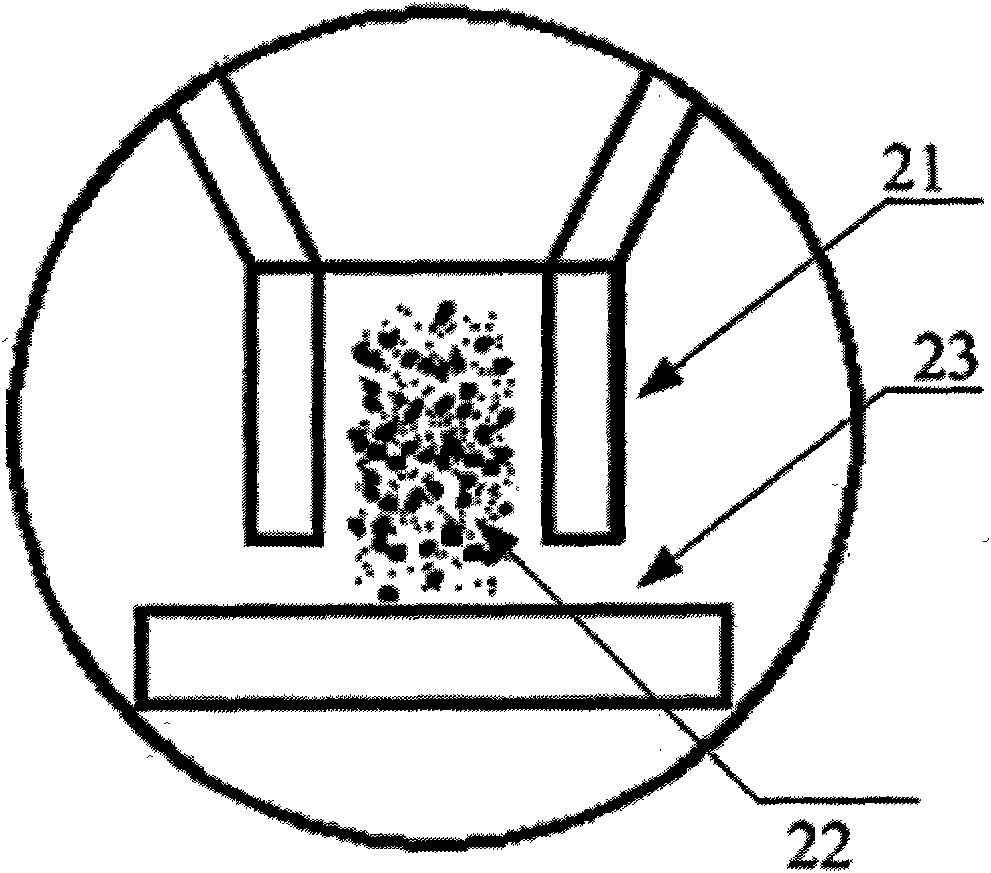

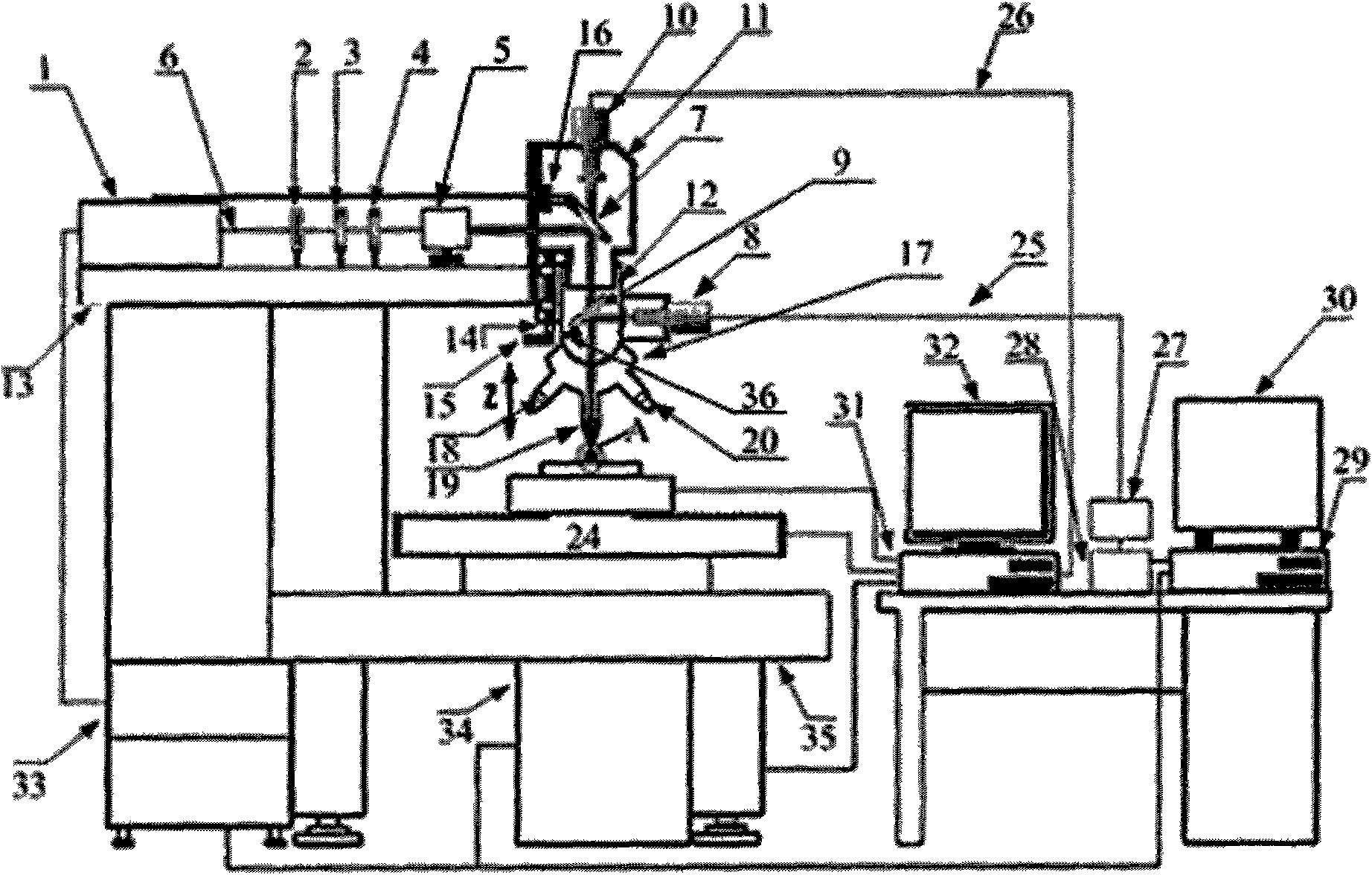

[0033] Such as figure 1 As shown, the laser probe micro-area component analyzer of the present invention includes a component analysis system (LIBS system), a sample optical observation system, a three-dimensional workbench, and a laser probe integrated control system. figure 2 for figure 1 Schematic diagram of zooming in at A.

[0034] The component analysis system includes a laser 1, a laser beam shaping light guide component, and a spectrum acquisition and analysis component.

[0035] Laser 1 usually adopts a tunable laser, and its wavelength range is continuously adjustable within the range of 215nm-2550nm; in the case of qualitative detection of some specific elements, a fixed wavelength laser can be used. The laser 1 is a laser with a small hole diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com