Preparing method of non-metal doped dye sensitization TiO2 nano-crystal thin film photoelectrode

A technology of dye-sensitized and thin-film electrodes, which is applied in the field of preparation of dye-sensitized TiO2 nanocrystalline thin-film photoelectrodes doped with non-metals, to achieve great cost advantages, easy operation, and improved photoelectric conversion efficiency

Inactive Publication Date: 2011-01-05

BEIJING UNIV OF CHEM TECH +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The non-metallic doping reported in the current literature is widely used in the field of photocatalysis, but no one has applied it to the field of solar cells

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

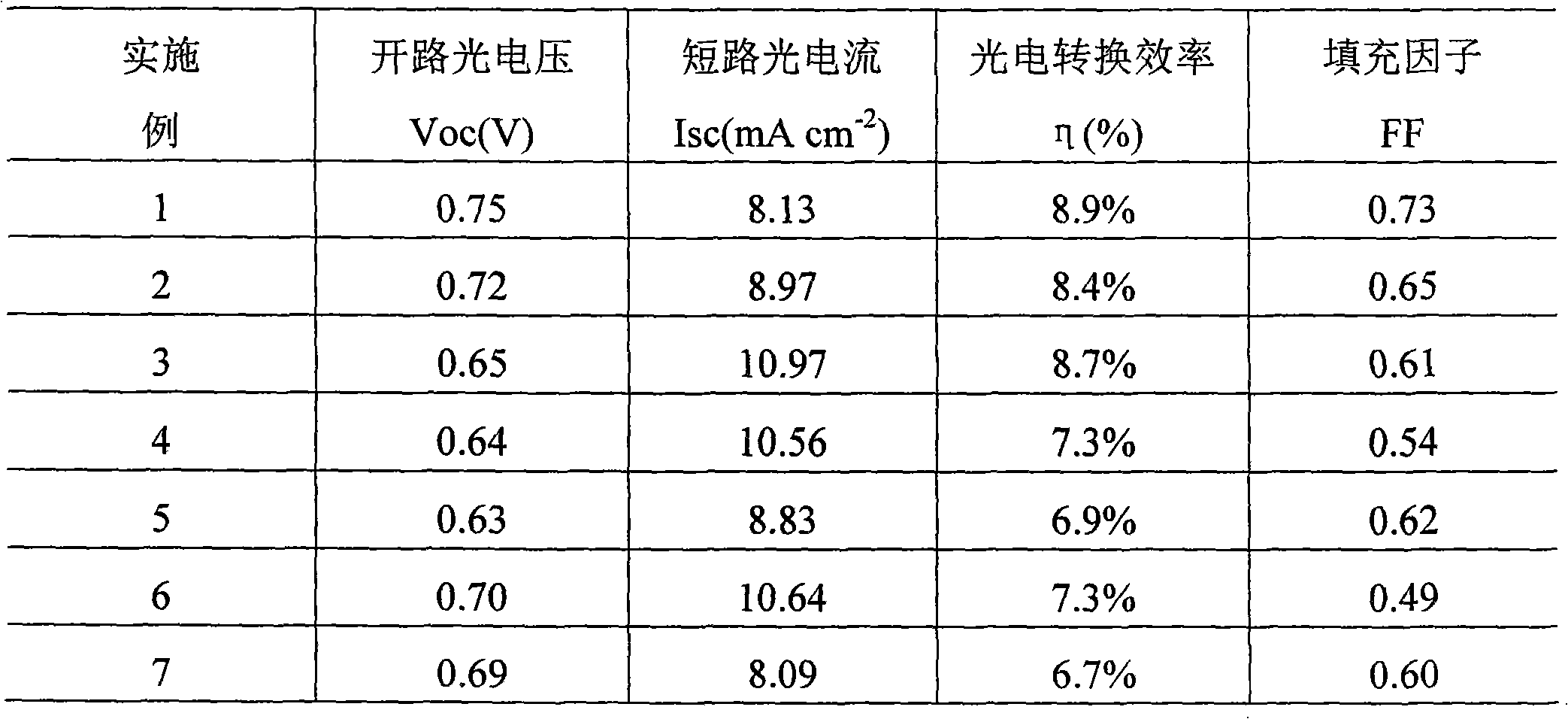

Login to View More Abstract

The invention belongs to the preparing field of TiO2 nano-crystal thin film photoelectrode of dye sensitization solar cell, especially relates to a preparing method of non-metal doped dye sensitization TiO2 nano-crystal thin film photoelectrode which is prepared by colloids containing non-metal doped large granule TiO2 nano-crystal and non-metal doped TiO2 nano-crystal granule. The photoelectrodeprepared by the invention is prepared by rotary coating the non-metal doped TiO2 colloidal sols and non-metal doped TiO2 power body slurry in order on a conductive substrate; after naturally drying, performing heat-treatment to obtain a nano-crystal thin film photoelectrode with porous structure. On one hand, the non-metal doped TiO2 nano-crystal granule changes the performance of the semiconductor, and is used as almsgiver to provide more carriers to improve the electric conductivity; on the other hand, the non-metal doped TiO2 nano-crystal granule changes the position of TiO2 energy band toimprove the photovoltage and the photo absorption efficiencies. The preparing method of the invention is simple and is easy to operate, is suitable for the industrial production preparation of the dyesensitization TiO2 nano-crystal thin film photoelectrode, and also is suitable for the fields of photochemical catalysis electrode and self-cleaning glass and so on.

Description

Preparation method of dye-sensitized TiO2 nanocrystalline thin film photoelectrode doped with non-metal technical field The invention belongs to the technical field of preparation of TiO2 nanocrystal thin film photoelectrodes of dye-sensitized solar cells, in particular to the preparation of colloids containing nonmetal-doped large-particle TiO2 nanocrystals and nonmetal-doped TiO2 nanocrystal particles. A method for metal dye-sensitized TiO2 nanocrystalline thin film photoelectrodes. Background technique The utilization technology of solar cells as the most ideal energy source has been valued and utilized by more and more countries in recent years. However, they have not been widely used. Comparable; silicon solar cell manufacturing itself is a huge energy-consuming industry. In recent years, a dye-sensitized solar cell has attracted the attention of researchers due to its simple manufacturing process, extremely low cost control, and many advantages such as conversion ef...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01G9/042H01M14/00H01L51/48

CPCY02E10/50Y02E10/549Y02P70/50

Inventor 张敬畅李启云杨秀英曹维良李海平

Owner BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com