Organic electroluminescent display device

An electroluminescent display and display device technology, which is applied in the direction of electric solid state devices, electrical components, semiconductor devices, etc., can solve the problems of no obvious improvement in device efficiency, lower hole injection barriers, lower device threshold voltage, etc., and achieve improved Effects of luminous efficiency and luminous brightness, increasing luminous flux, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below, which is an explanation of the present invention rather than a limitation.

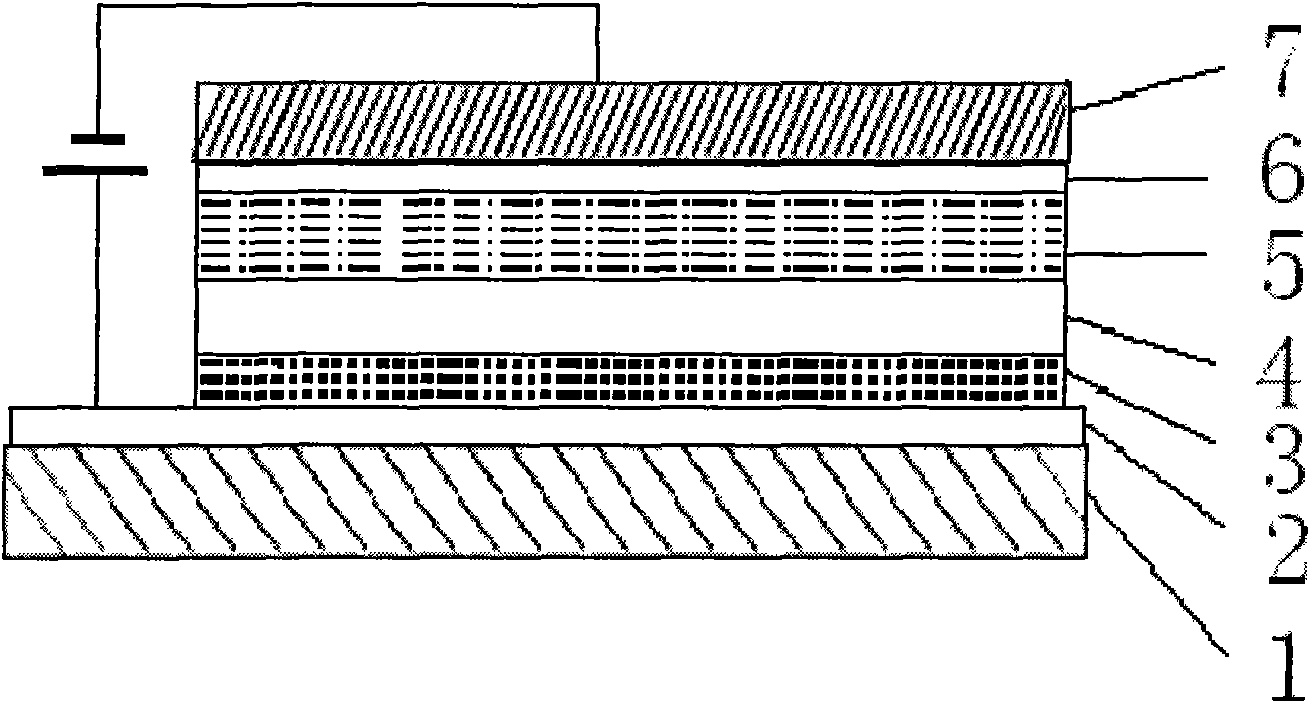

[0022] Such as figure 1 As shown, the organic electroluminescent display device provided by the present invention includes a glass substrate 1, and an ITO conductive layer 2, an anode interface modification layer 3, a hole transport layer 4, an electron Transport layer and luminescent layer 5, metal cathode Mg layer 6 and metal cathode layer 7, wherein, ITO conductive layer 2 and metal cathode Al layer 7 are respectively connected to the positive and negative electrodes of DC voltage, and the anode interface modification layer is doped with ZnO In the PEDOT:PSS layer of nanoparticles, the ZnO doped is 1%-10% of the mass of PEDOT:PSS.

[0023] The preparation of the ZnO-doped PEDOT:PSS anode interface modification layer solution is:

[0024] ZnO nanoparticles were added to a 5% PEDOT:PSS aqueous solution, and magnetically stirred at room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com