Tapered bushing for line and bar rolling mill

A tapered bushing and rolling mill technology, which is applied in the field of wire rod and bar rolling, can solve the problems of piled steel accidents, permanent poor contact, small effective contact area, etc., and achieve the effect of increasing the service life and improving the contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

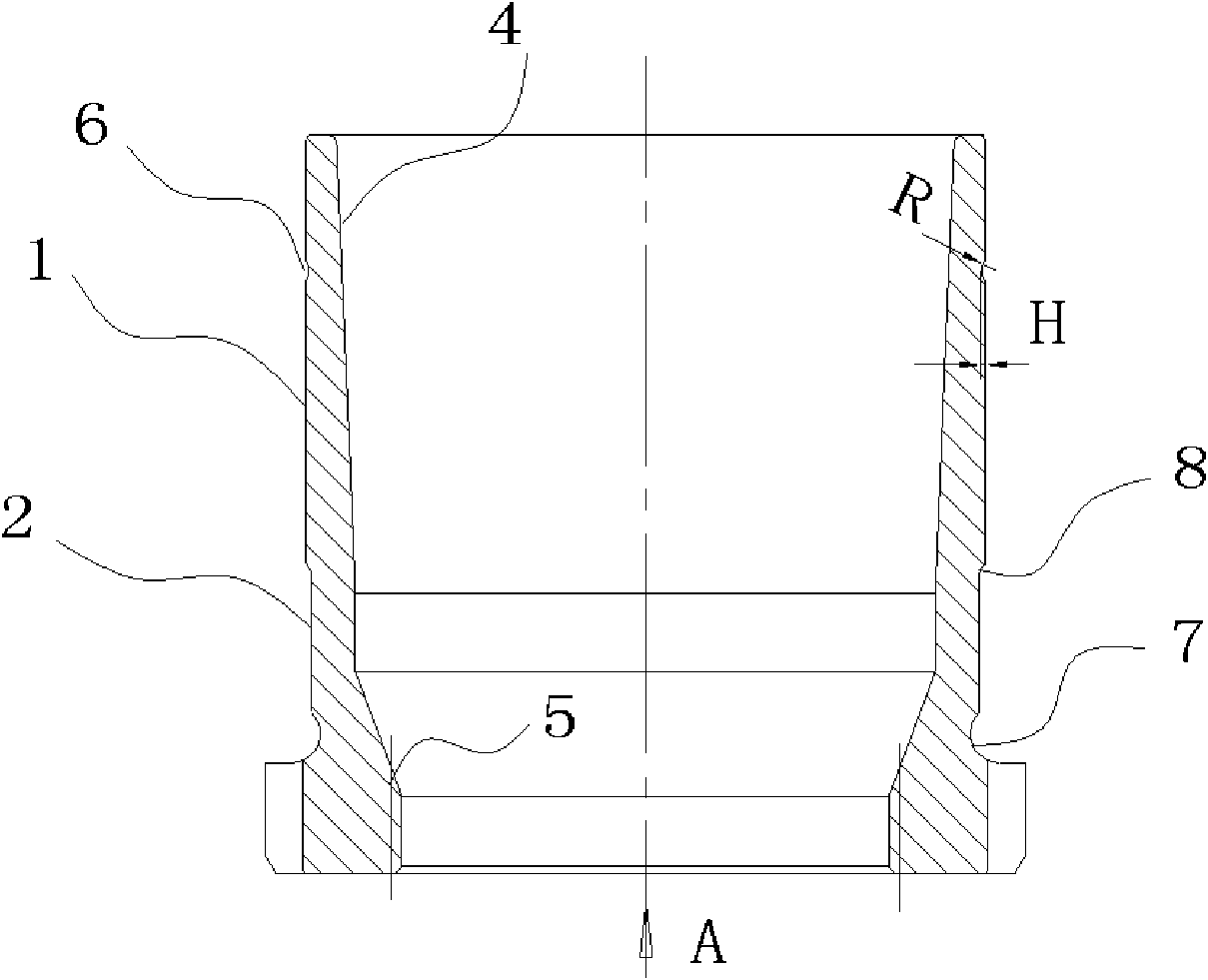

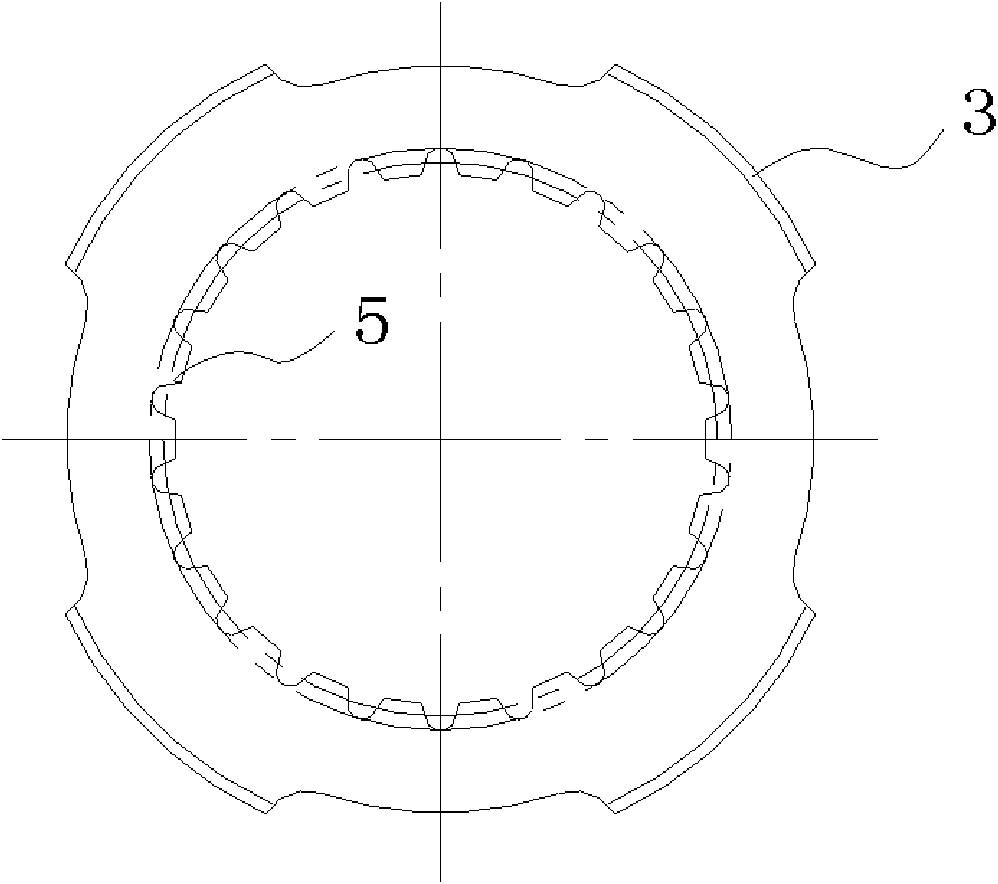

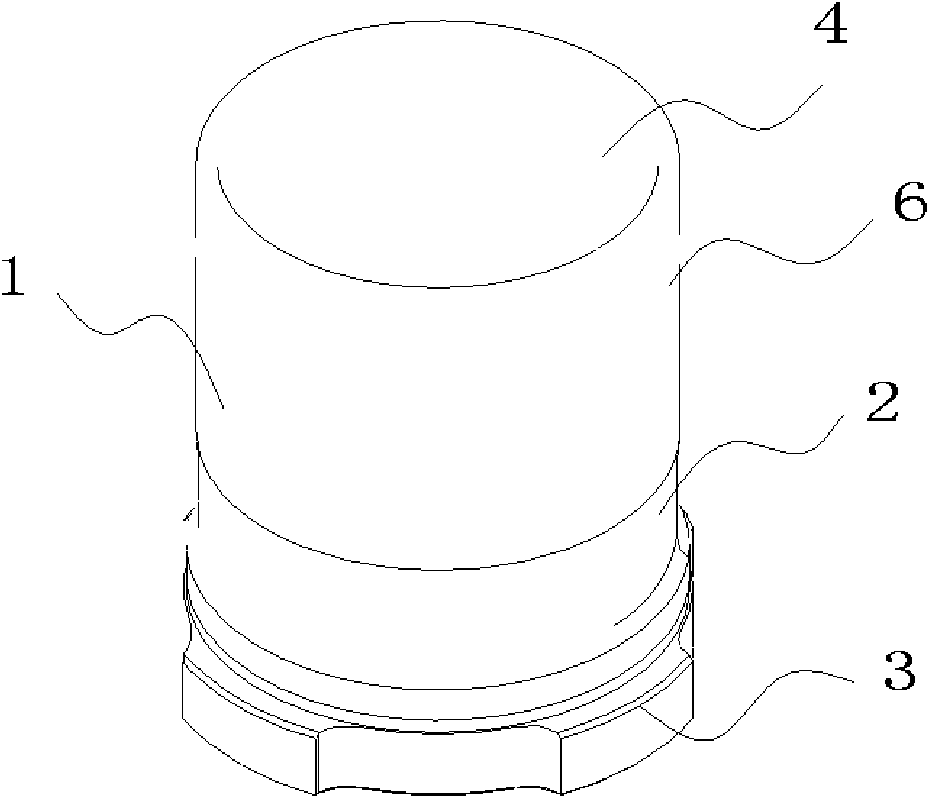

[0032] In the following, the technical solutions of the present invention will be further described in detail through the embodiments and in conjunction with the drawings.

[0033] The tapered bushing for the wire and rod rolling mill of this embodiment includes a cylinder with an inner conical surface 4 of the tapered sleeve. The material of the cylinder is heat-resistant martensitic stainless steel 0Cr17Ni4Cu4Nb.

[0034] 0Cr17Ni4CmNb steel is a kind of martensitic precipitation hardening stainless steel made by adding Cu, Nb and other strengthening elements on the basis of Cr17 stainless steel. Its strength is achieved through precipitation hardening by martensitic transformation and aging in the temperature range of 400-650℃, precipitation hardening phases such as rCu, NbC, M23C6 and other carbides.

[0035] This steel has low carbon, high chromium, and contains copper, nickel, and niobium. Its corrosion resistance is better than that of martensitic steels such as Cr13 and Cr2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com