Method for concentrating at low temperature and pretreating concentrated solution

A pretreatment, low temperature technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of difficult separation of trimethylolpropane, affecting product purity and color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

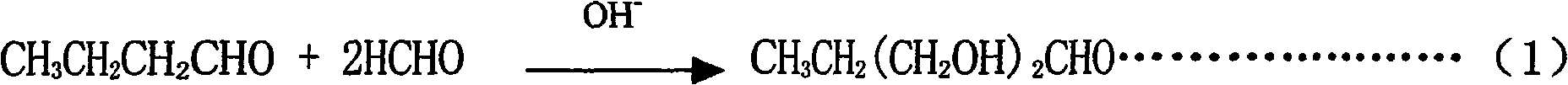

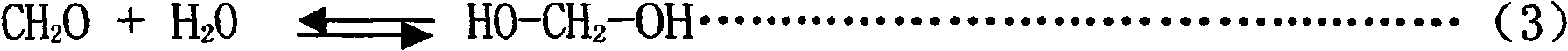

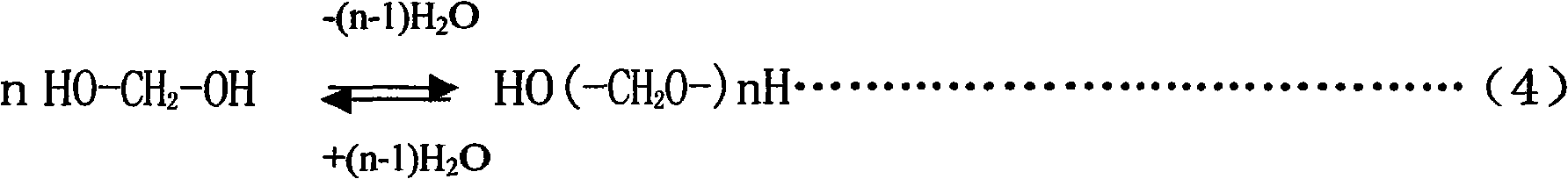

Method used

Image

Examples

Embodiment

[0040] Pump 1250kg of formaldehyde solution with a mass fraction of 37% into the batching kettle, add 2050kg of remixed water obtained from the dealdehyde / dealcoholization process for dilution, and make up the rest with deionized water to obtain 6000kg of dilute formaldehyde solution with a mass fraction of 8% ;

[0041] Turn on the freezer, turn on the stirring, freeze the formaldehyde solution used in the above reaction to 10°C, and then add the frozen dilute formaldehyde solution to the condensation kettle;

[0042] 339kg of n-butyraldehyde and 723kg of mass fraction of 32% liquid caustic soda are divided into two parts, the first part of n-butyraldehyde is 3 / 4 of the calculated mass of n-butyraldehyde, i.e. 254kg, and the remainder is the second part, liquid caustic soda The first part is 1 / 3 of the calculated mass of liquid caustic soda, i.e. 241kg, and the remainder is the second part. Add the first part of n-butyraldehyde and liquid caustic soda at a uniform speed of 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com