Method for processing foundation through one-time pipe insertion and multi-time vacuum well point precipitation dynamic consolidation

A technology for foundation treatment and well point dewatering, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of prolonging the construction period, duplicating labor, and increasing the time interval of compaction, so as to improve the compactness and suppress the water level The rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

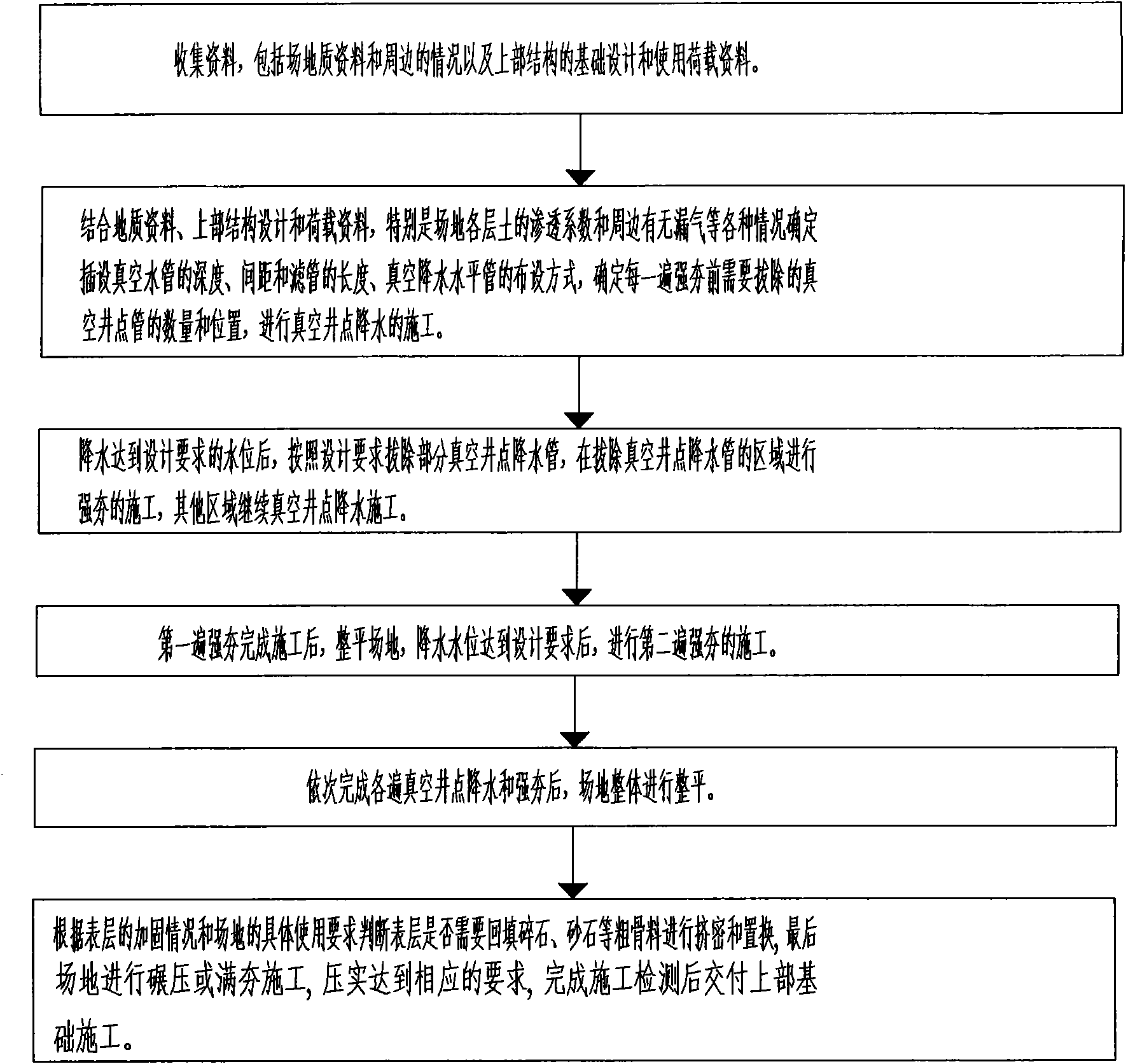

[0028] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0029] The process of the present invention combines the respective advantages of dynamic compaction, one-time intubation, and multiple vacuum well point dewatering, and utilizes one-time intubation and multiple vacuum well point dewatering to reduce the water level, accelerate soil consolidation and pore water pressure dissipation, and give full play to The advantages and effects of dynamic compaction treatment, the surface layer forms a "hard shell" with a certain thickness and strength, which has the advantage of more coordinated uneven settlement deformation.

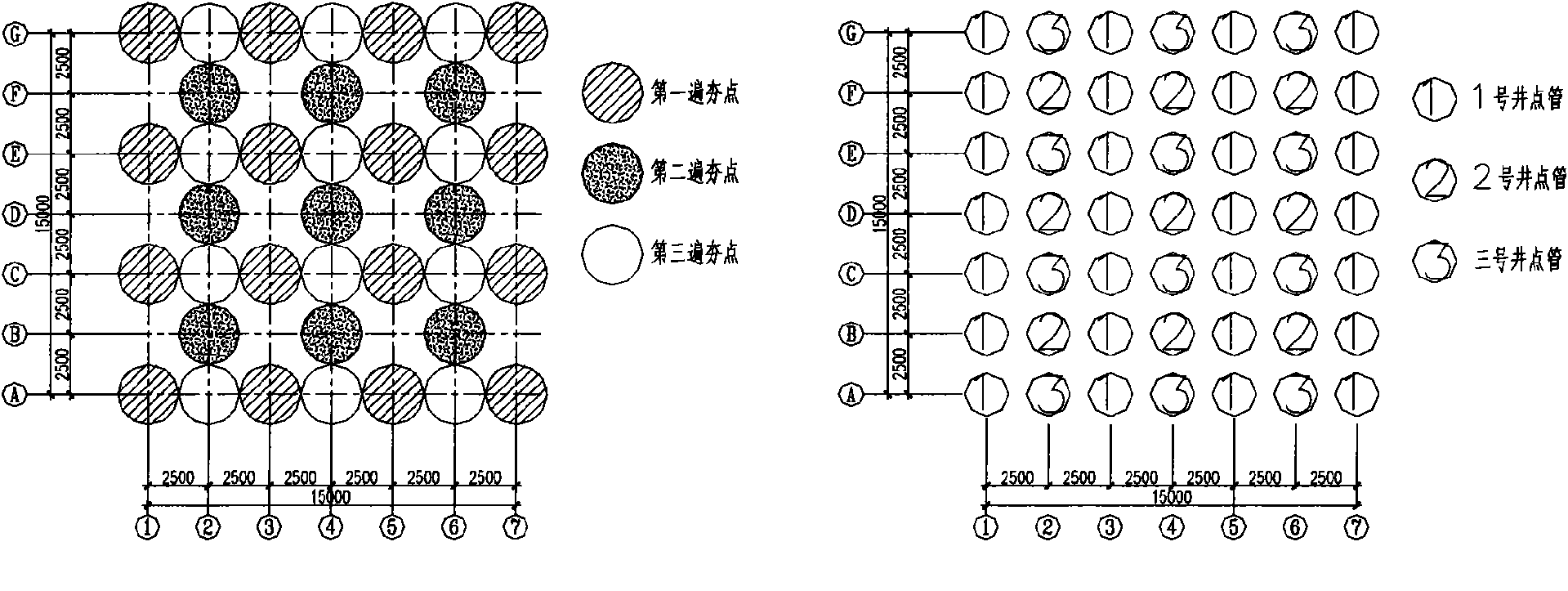

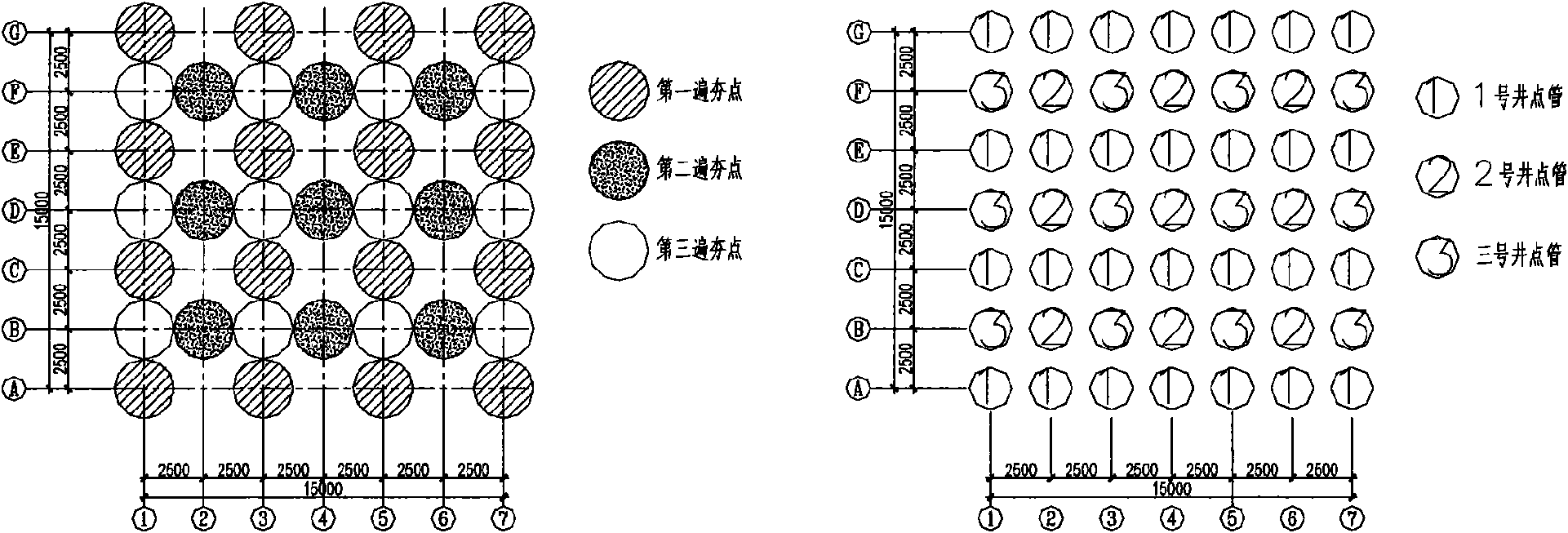

[0030] Figure 2 ~ Figure 3 It is a relative schematic diagram of two different vacuum well point water pipes and dynamic compaction points of the present invention. In the specific implementation, according to the layout spacing and method of vacuum well point water pipes, differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com