Method and device for controlling waste heat recovery system of kiln

A waste heat recovery system and control method technology, applied in the direction of furnace control devices, furnaces, waste heat treatment, etc., can solve the problems of high operation intensity and difficulty, inflexible operation, and low control accuracy, so as to reduce the operation intensity and difficulty, Improve control accuracy and prevent misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

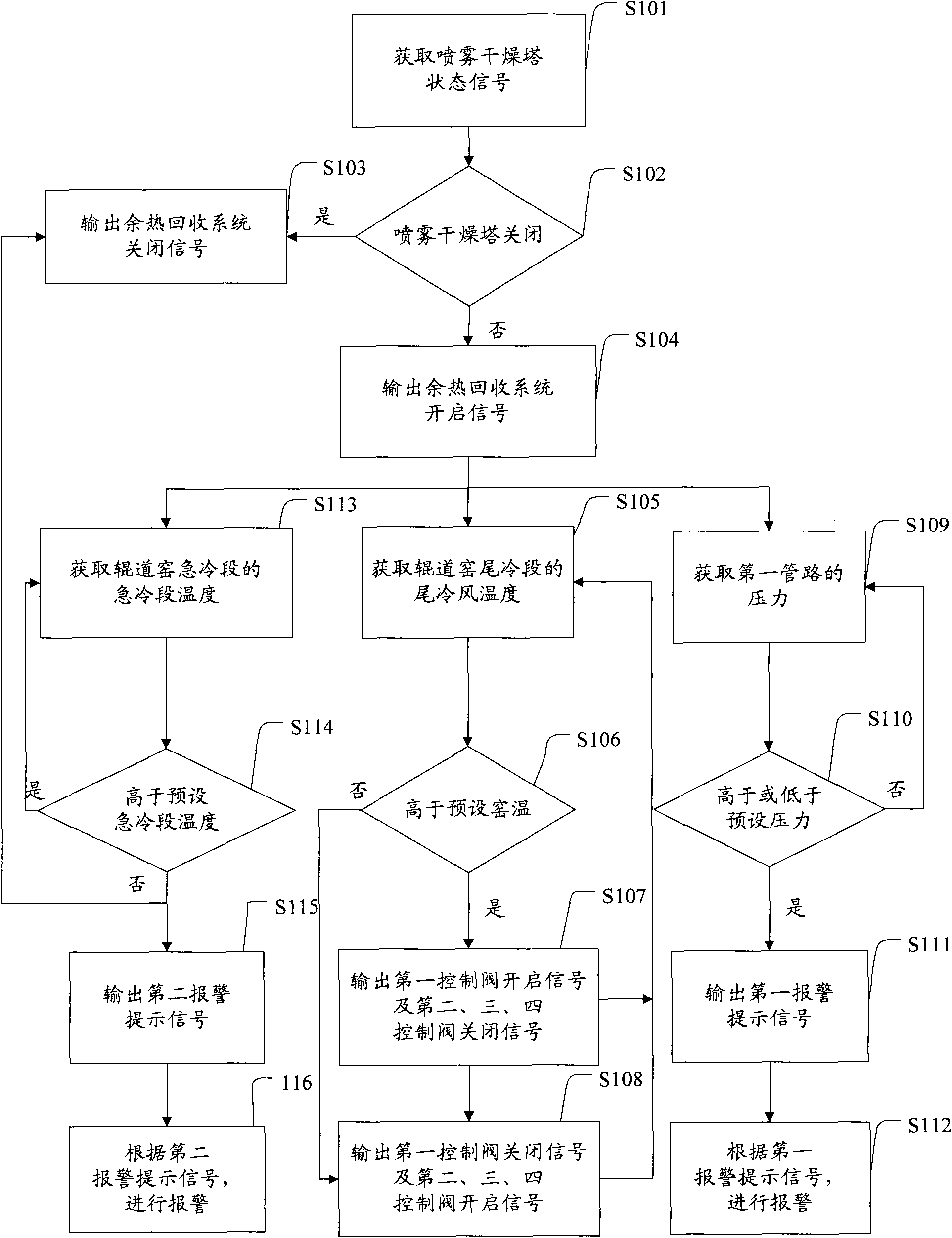

[0044] The following will be described in conjunction with the accompanying drawings and embodiments.

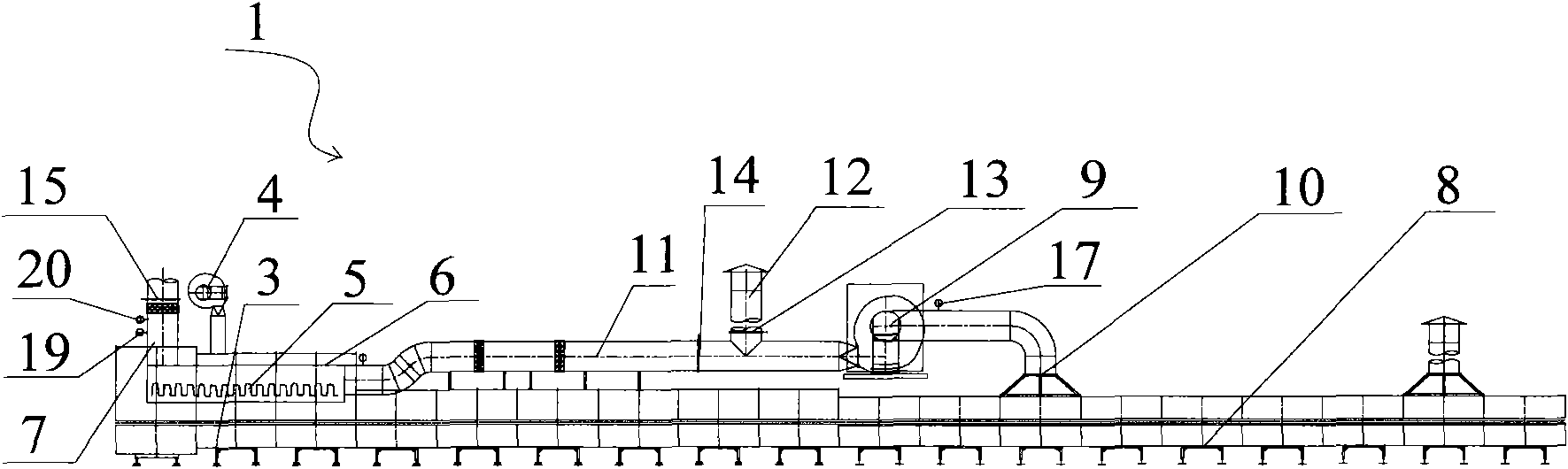

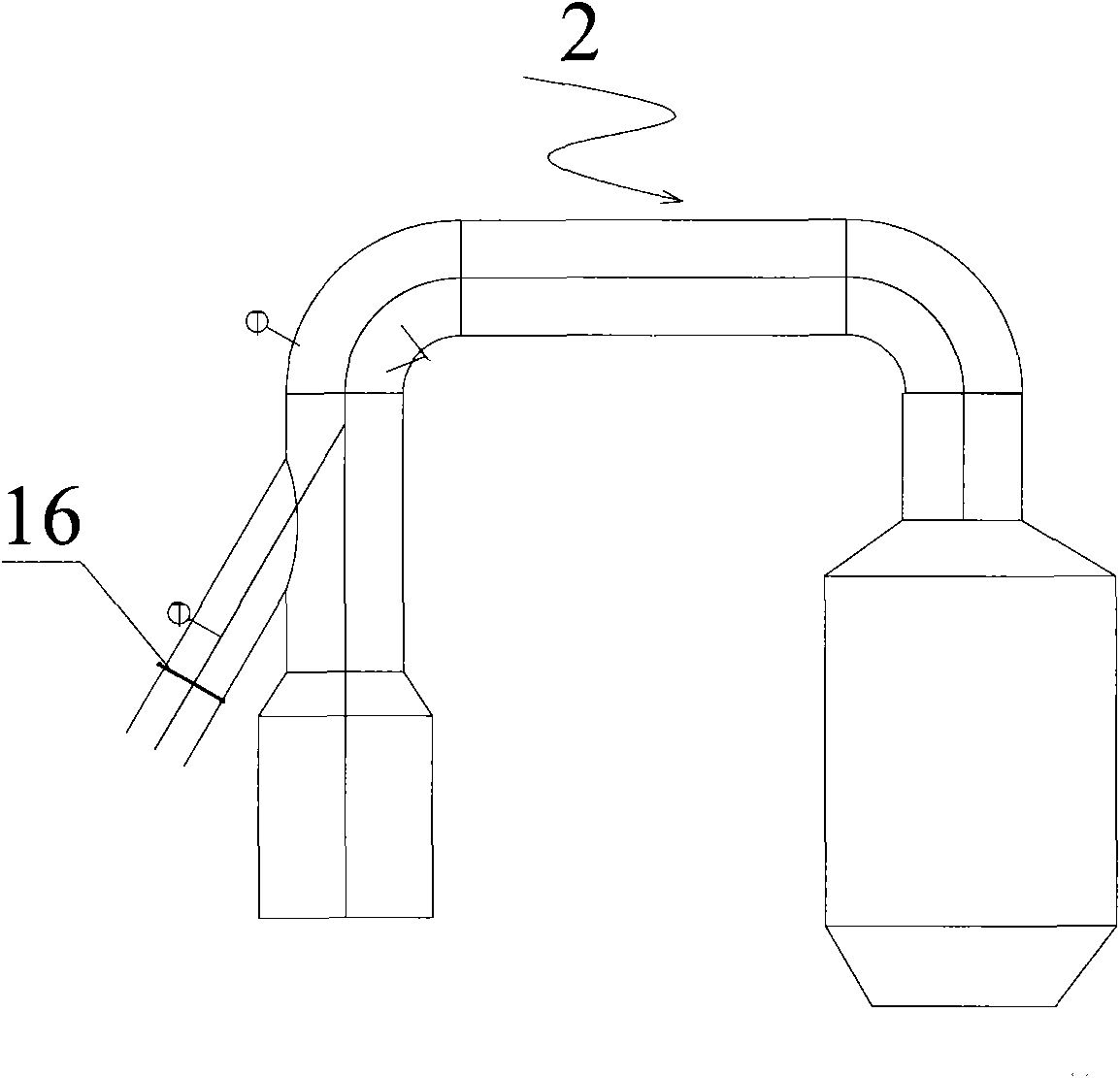

[0045] See figure 1 , figure 2 ,in: figure 1 It is a schematic diagram of the roller kiln in the kiln waste heat recovery system of the present invention; figure 2 It is a schematic diagram of the spray drying tower in the kiln waste heat recovery system of the present invention. The control method of the kiln waste heat recovery system of the present invention is specifically adapted to figure 1 , figure 2 The shown kiln waste heat recovery system includes a roller kiln 1 and a spray drying tower 2; the quenching section 3 of the roller kiln 1 is provided with a quenching fan 4 and a heat exchange box 6 with a heat exchanger 5 inside. Body 6 communicates with spray drying tower 2 through first pipeline 7, and is cut off from the quenching channel of roller kiln 1; end cooling section 8 of roller kiln 1 is provided with waste heat fan 9 and exhaust hood 10, and this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com