Excimer lamp

A technology of excimer lamps and particles, applied in the field of excimer lamps, can solve the problems of changes in processing capacity of excimer lamps and reduction of illuminance maintenance rate, and achieve the effect of maintaining illuminance and suppressing the degree of illuminance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

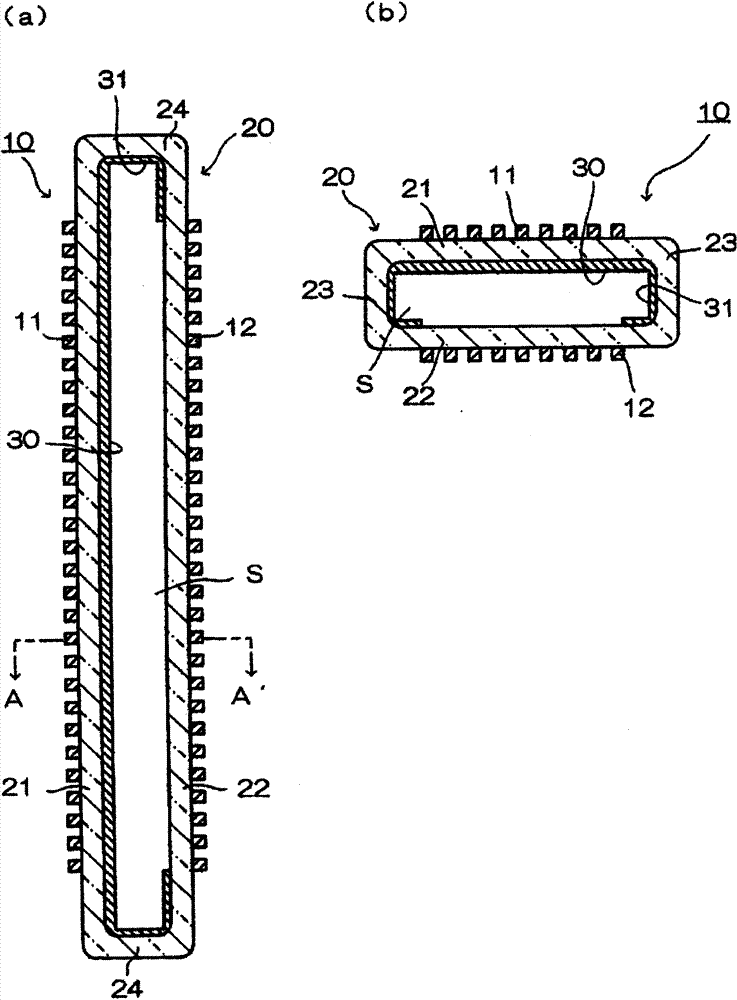

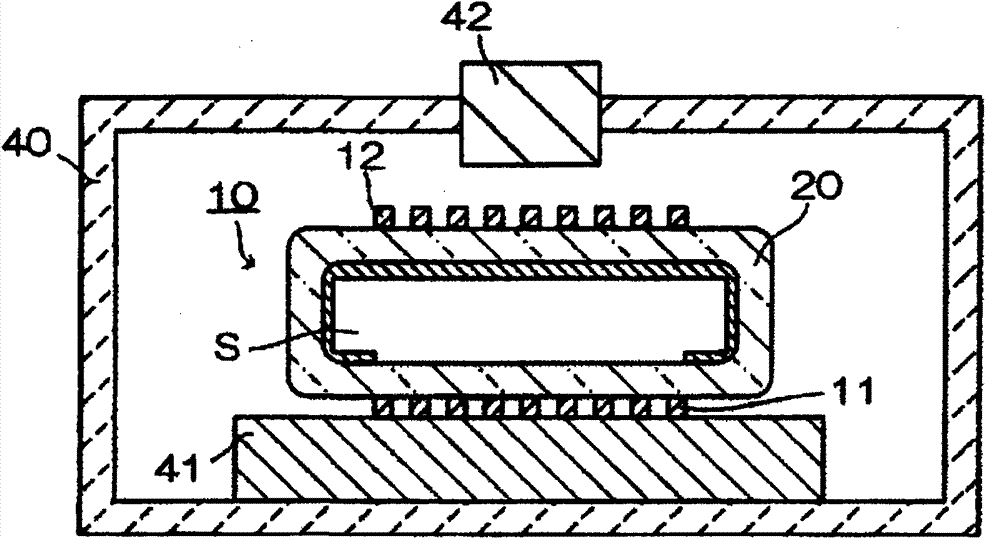

[0052] according to figure 1 With the configuration shown in (a) and (b), an excimer lamp provided with an ultraviolet reflection layer was produced.

[0053] [Basic configuration of an excimer lamp]

[0054] The material of the discharge vessel is silica glass, the size is 15mm×43mm×350mm, and the thickness is 2.5mm.

[0055] The size of the high voltage supply electrode and the ground electrode is 30mm×300mm.

[0056] The ultraviolet reflective layer is composed of a mixture of silica particles with a central particle diameter of 1.5 μm in a composition ratio of 90% by weight and alumina particles with a central particle diameter of 1.5 μm in a composition ratio of 10% by weight, which are formed separately by a flow-down method and calcined. The temperature is 1000°C.

[0057] As a discharge gas, xenon was sealed in the discharge vessel at 40 kPa.

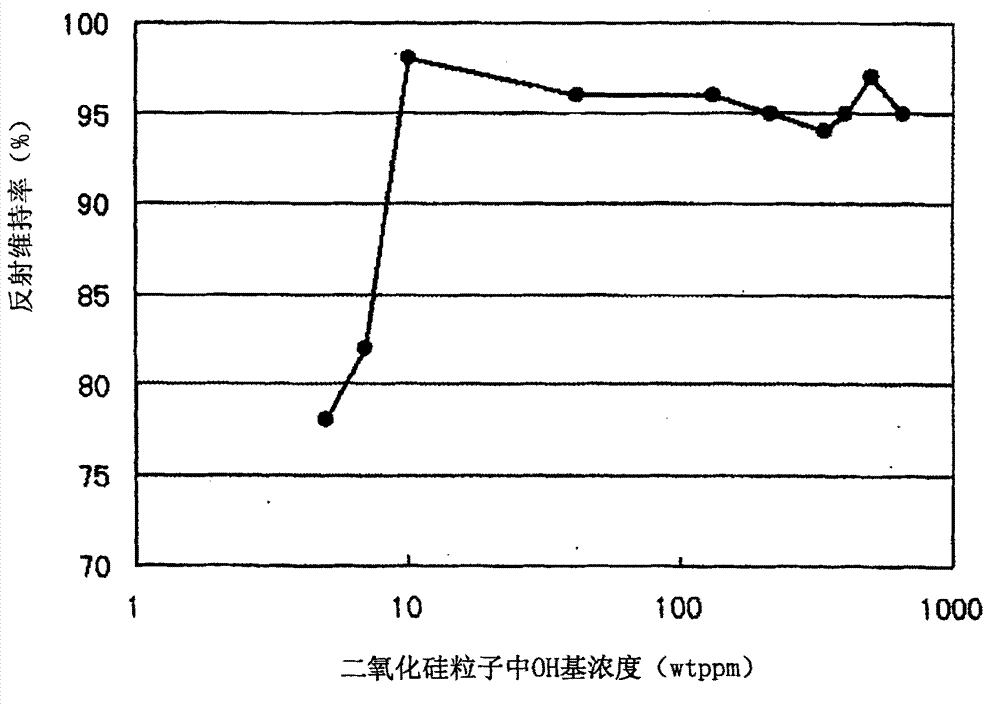

[0058] Ten types of excimer lamps having the above-mentioned configurations, namely, lamps 1 to 10 having different heati...

experiment example 2

[0081] The same measurement as in Experimental Example 1 was performed on an excimer lamp in which the central particle diameter and composition ratio of silica particles and alumina particles, which are constituent materials of the ultraviolet reflection layer, were changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com