Titanium alloy for laser solid forming and laser shaping repairing

A laser forming repair and laser three-dimensional forming technology, which is applied in the coating process and coating of metal materials, can solve problems such as mismatching mechanical properties, and achieve the effect of reducing strength and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

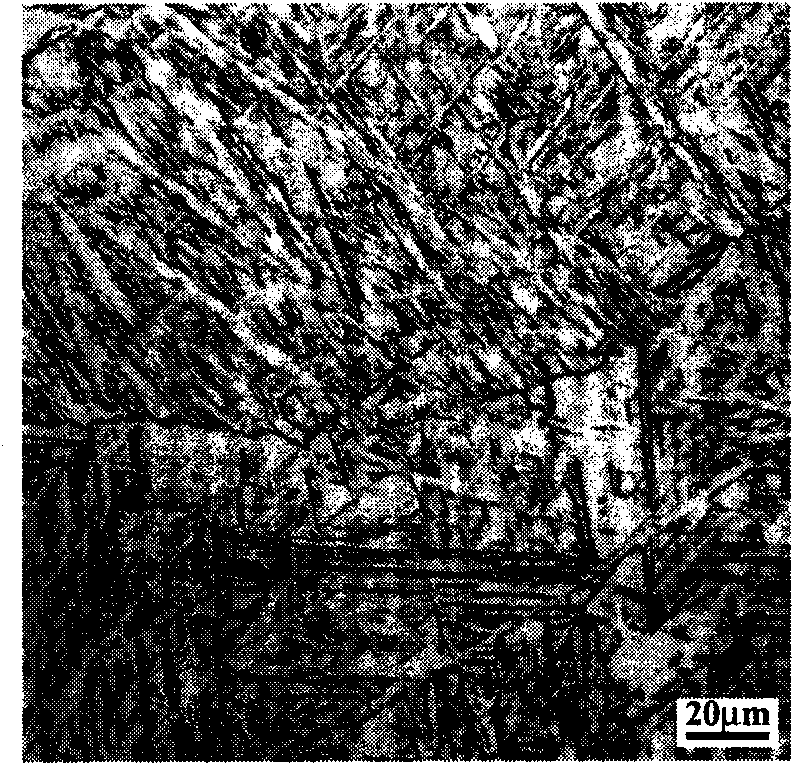

Embodiment 1

[0013] The mechanical properties at room temperature of the laser deposition state in this embodiment are: tensile strength 910 MPa, yield strength 840 MPa, elongation 17.0%, and reduction of area 50%. The present invention is a special titanium alloy for laser three-dimensional forming and repairing. The titanium alloy includes titanium, aluminum, and vanadium. In this embodiment, the ratio of each alloy component is: aluminum 3.6wt%, vanadium 2.1%, The rest is titanium, and the total amount does not exceed 100%.

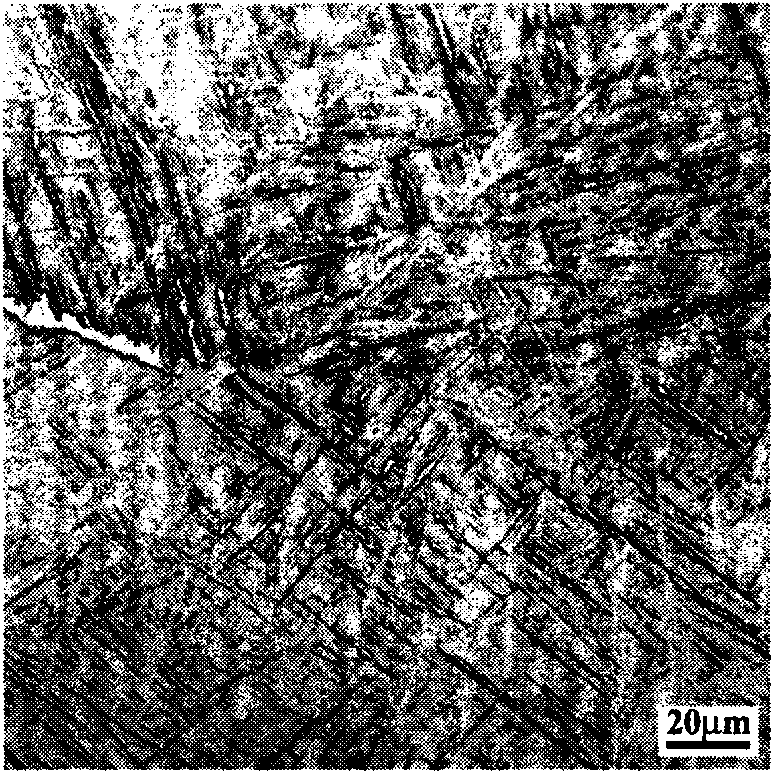

Embodiment 2

[0015] The mechanical properties at room temperature of the laser deposition state in this embodiment are: tensile strength 935 MPa, yield strength 870 MPa, elongation 15.0%, and reduction of area 46%. The present invention is a special titanium alloy for laser three-dimensional forming and repairing. The titanium alloy includes titanium, aluminum, and vanadium. In this embodiment, the ratio of each alloy component is: aluminum 3.9wt%, vanadium 2.8%, The rest is titanium, and the total amount does not exceed 100%.

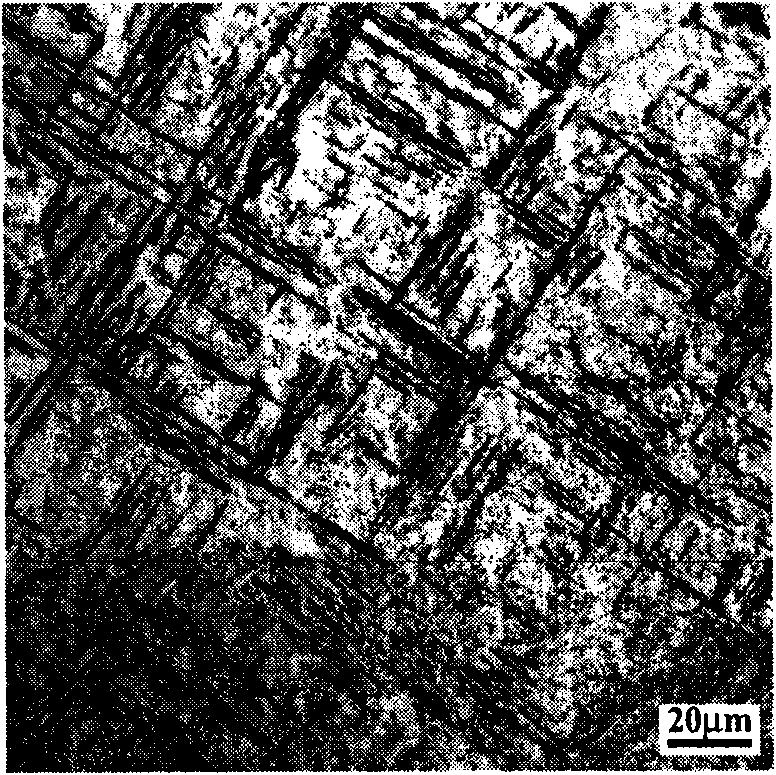

Embodiment 3

[0017] The room temperature mechanical properties of the laser deposition state in this embodiment are: tensile strength 980 MPa, yield strength 915 MPa, elongation 13.0%, and reduction of area 39%. The present invention is a special titanium alloy for laser three-dimensional forming and repairing. The titanium alloy includes titanium, aluminum, and vanadium. In this embodiment, the proportion of each alloy component is: aluminum 5.0wt%, vanadium 3.4%, The rest is titanium, and the total amount does not exceed 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com