Positive pole of lithium manganese battery

A lithium-manganese battery and positive electrode technology, applied in the field of electrochemistry, can solve the problems of uneven discharge voltage curve, affecting wide application, low battery capacity and high current output performance, and achieve the effect of increased capacity and stable discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

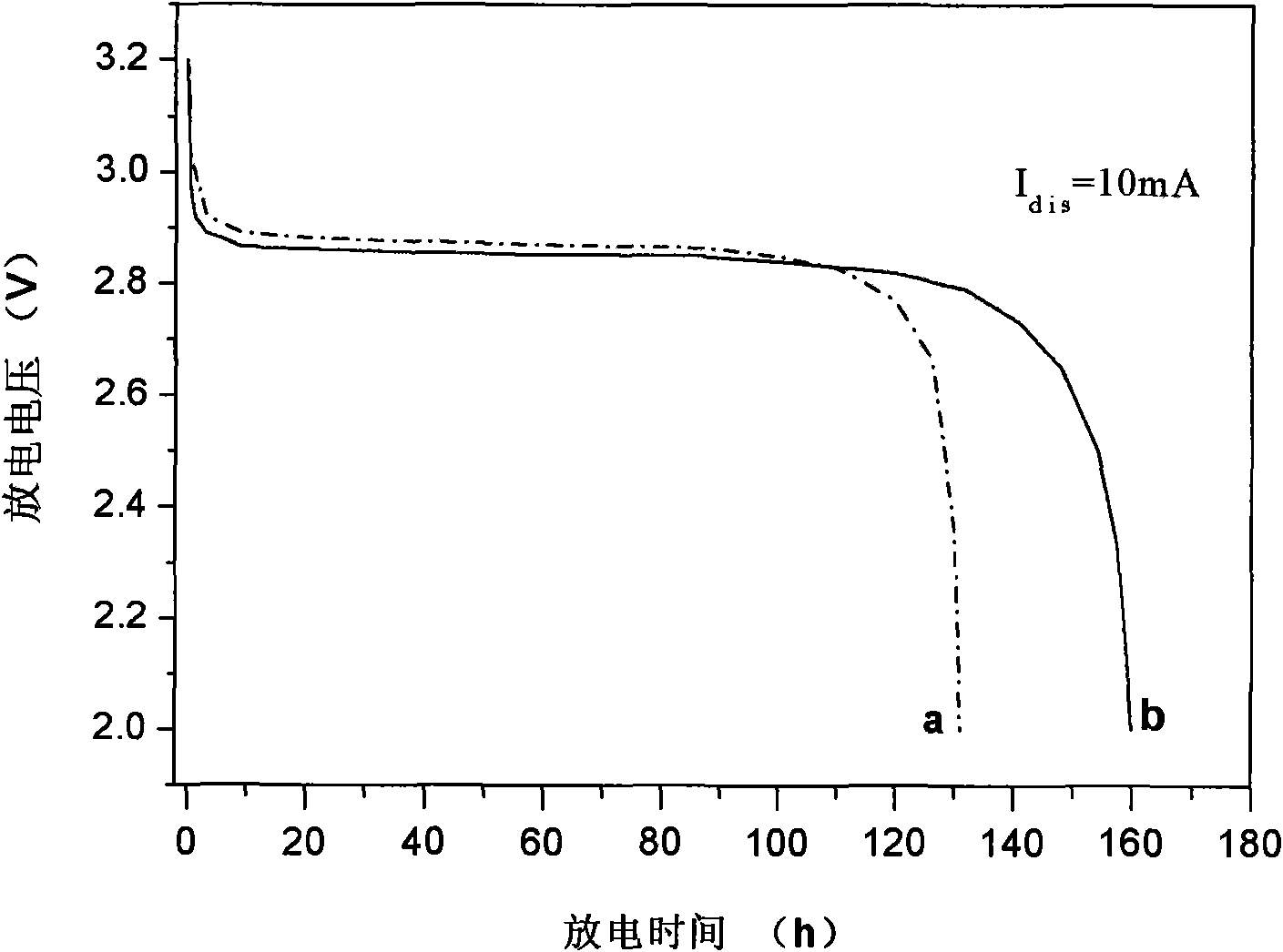

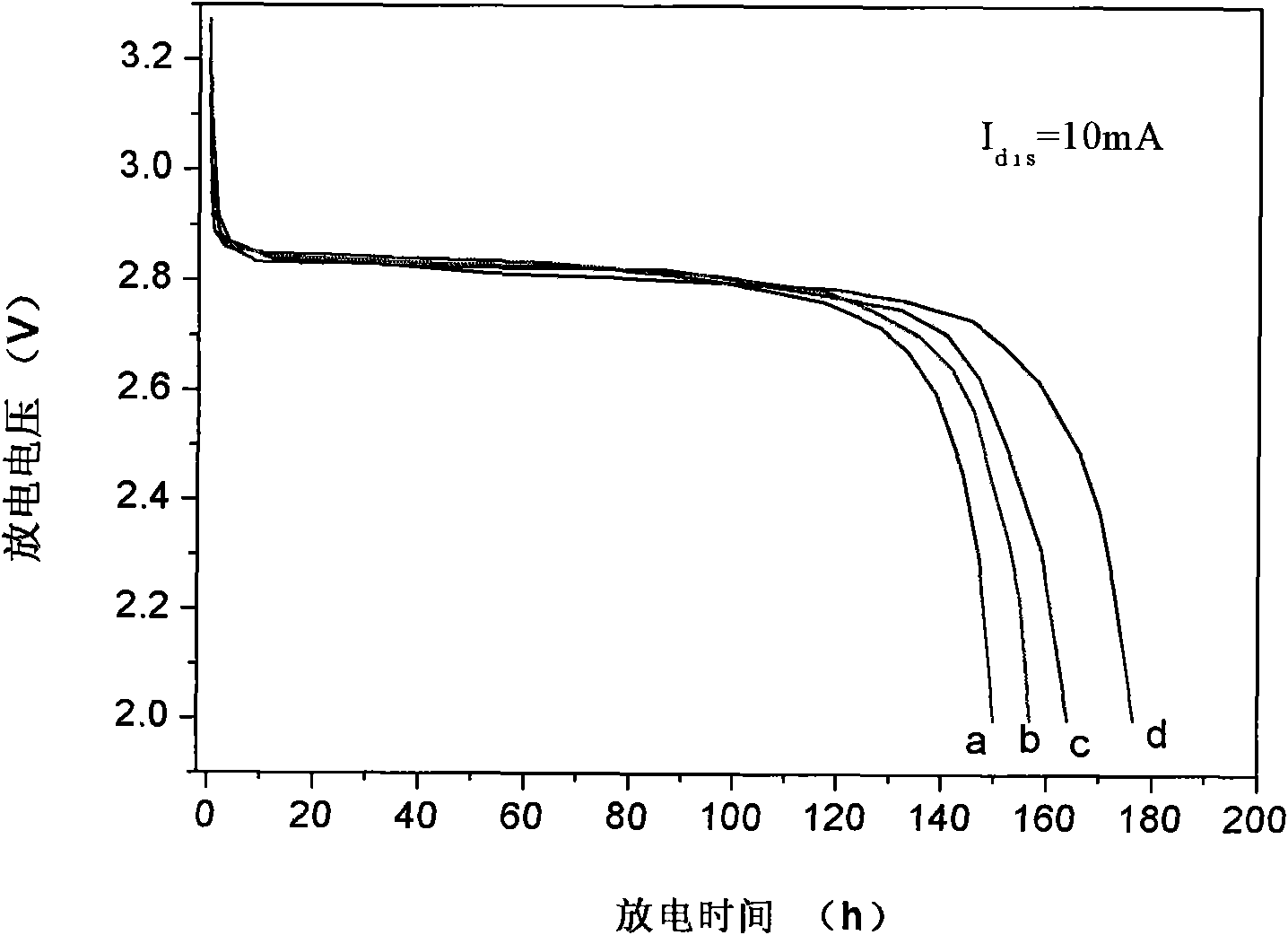

[0017] Example 1: Manganese dioxide: graphite: polytetrafluoroethylene: fluorinated carbon fiber (the mass content of fluorine is 40%)=1: 0.06: 0.05: 0.01 is fully mixed, granulated, rolled, and prepared as positive electrode. With lithium metal as the negative electrode, the separator is Celgard 2300, 1mol / L lithium perchlorate (LiClO 4 ) / propylene carbonate (PC)+ethylene glycol dimethyl ether (DEC) (volume ratio 1:1) as the electrolyte, and assembled into a CR123A lithium battery in an argon glove box. The battery adopts constant current discharge, the discharge cut-off voltage is 2.0V, and the discharge performance test is performed in an environment of 23±2°C. Discharge curve such as Figure 3 song line a.

example 2

[0018] Example 2: Manganese dioxide: graphite: polytetrafluoroethylene: graphite fluoride (the mass content of fluorine is 65%)=1: 0.07: 0.07: 0.05 is fully mixed, granulated, rolled, and prepared as positive electrode. Use metal lithium as the negative electrode, the separator is Celgard 2300, 1mol / L LiClO 4 / PC+DMC (volume ratio 1:1) was used as the electrolyte, and a CR123A lithium battery was assembled in an argon glove box. The battery adopts constant current discharge, the discharge cut-off voltage is 2.0V, and the discharge performance test is performed in an environment of 23±2°C. Discharge curve such as Figure 3 song line b

example 3

[0019] Example 3: Manganese dioxide: graphite: polytetrafluoroethylene: fluorinated carbon nanotubes (the mass content of fluorine is 35%)=1: 0.08: 0.06: 0.15 is fully mixed, granulated, rolled, and prepared as Positive electrode, lithium metal as negative electrode, Celgard 2300 separator, 1mol / L LiClO 4 / PC+DMC (volume ratio 1:1) was used as the electrolyte, and a CR123A lithium battery was assembled in an argon glove box. The battery adopts constant current discharge, the discharge cut-off voltage is 2.0V, and the discharge performance test is performed in an environment of 23±2°C. Discharge curve such as Figure 3 song line c

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com