A method for producing low-alkali cement by utilizing high-alkali raw materials

A low-alkali cement and raw material technology, which is applied in clinker production, cement production, alkali metal chloride, etc., can solve the problems that low-alkali cement cannot meet the needs of low-alkali cement and low-alkali raw materials are insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

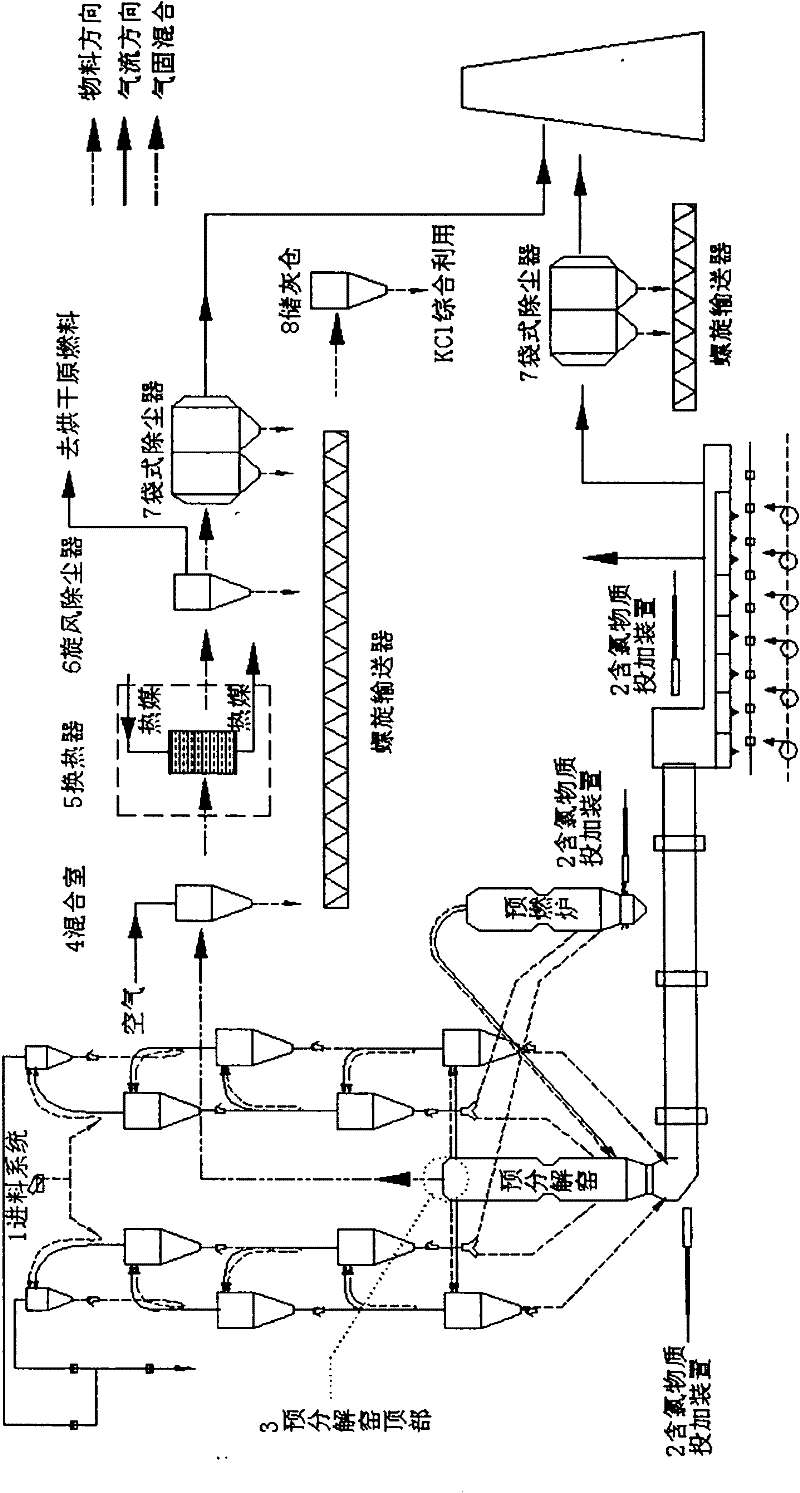

Image

Examples

Embodiment 1

[0041] The production line of a cement plant has a daily output of 3,000 tons of cement clinker (consumption of about 3,000 tons of hot raw materials and about 4,500 tons of raw materials) (using a dry-process cement rotary kiln with a suspension preheater and a precalciner kiln). See Table 1 and Table 2 below for the element content of raw materials and cement products before adding Cl element.

[0042] Table 1 The content of each element in the hot raw meal entering the kiln (%)

[0043] SiO 2

[0044] Content of each element in table 2 cement (%)

[0045] SiO 2

[0046] Under this condition, the alkali equivalent of the cement product is 0.14%+0.658×1.16%=0.90328%, which is greater than 0.60%, which does not meet the requirements of low-alkali cement.

[0047] Calculate the amount of added chlorine should be greater than 14.7 tons, less than 38.97 tons, see the following formula (4) and (5). Add 30 tons of PCB to the kiln system through the kiln he...

Embodiment 2

[0054] A cement plant production line produces 3000 tons of cement clinker per day (dry process cement rotary kiln with suspension preheater and precalciner kiln). 5.

[0055] Table 4 The content of each element in the hot raw meal entering the kiln (%)

[0056] SiO 2

[0057] Content of each element in table 5 cement (%)

[0058] SiO 2

[0059] Calculate the amount of added chlorine should be greater than 19.07 tons, less than 41.24 tons see the following formula (6) and (7). Add 7.5 tons of fly ash per hour to the kiln system through the kiln head, with a Cl content of 12%. And through the device provided by the invention, 10% of the system air volume is extracted, and the hot flue gas first passes through the mixing chamber to cool down and then enters the heat exchanger, where the heat transfer oil in the heat exchanger is heated, and the heat transfer oil provides heat for other heat-requiring equipment. The flue gas coming out of the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com