Method for producing biomass solid shaping fuel by catalytic mild carbonization method

A technology of solidification molding and molding fuel, which is applied in the direction of biofuel, solid fuel, waste fuel, etc., can solve the problems of complex operation, difficult maintenance of molding equipment, high production cost, etc., achieve simple operation, improve curing molding performance and heat density, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

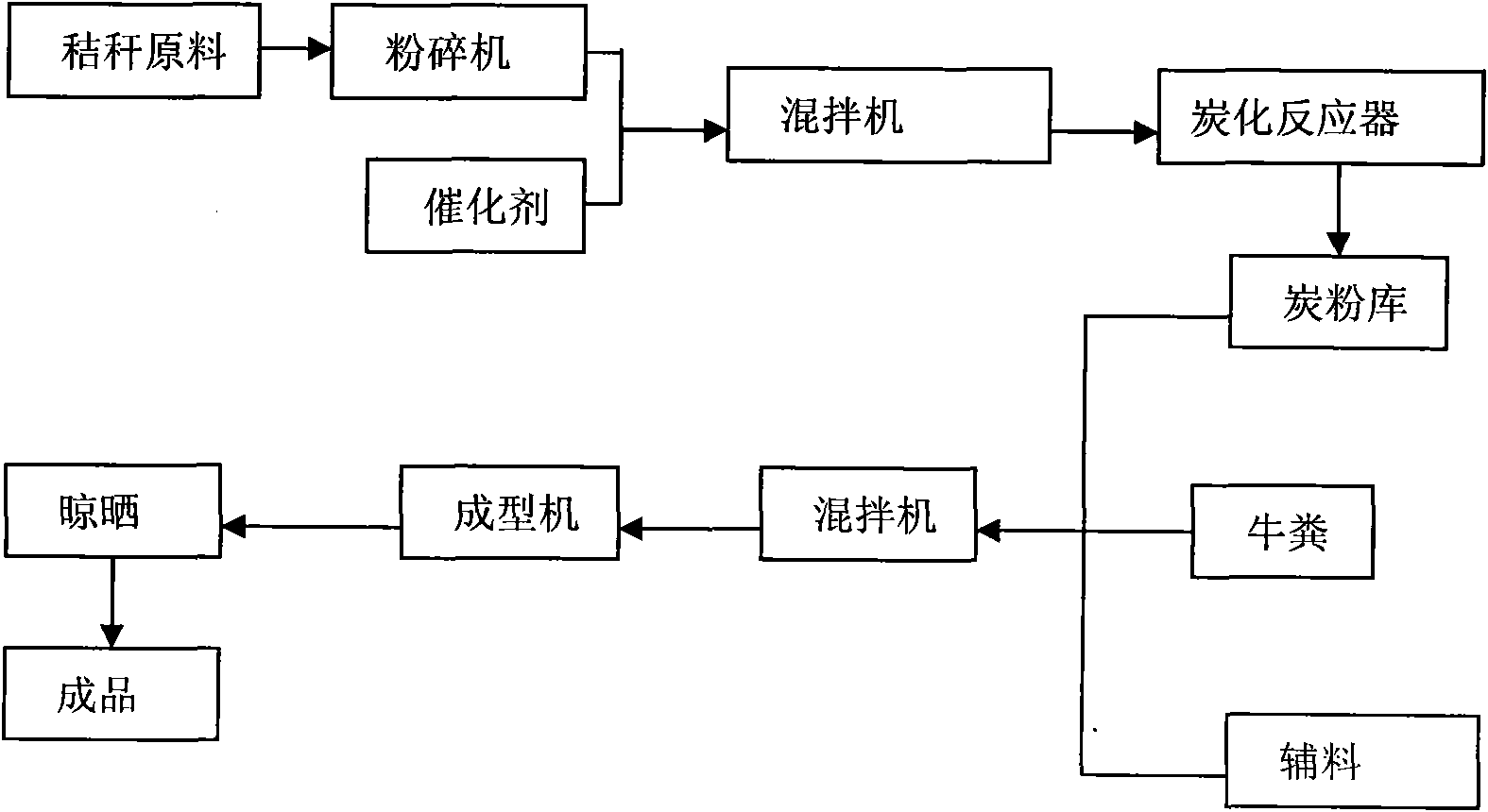

[0010] Specific Embodiment 1: In this embodiment, the method for producing biomass solidified briquette fuel by catalytic light carbonization method is carried out according to the following steps: 1. Crush the straw into straw powder with a particle size of 0.5-3 mm, and then mix the straw powder and catalyst according to The mass ratio is 10:0.6~1, and then placed in a carbonization reactor at a temperature of 120~220°C for 30~90 minutes to obtain straw charcoal powder; 2. Mix 4~10 parts of straw Charcoal powder, 0.8-1.2 parts of auxiliary materials, 0-6 parts of cow dung with a moisture content of 0.5-50% and 0-6 parts of biogas residue with a moisture content of 0.5-50% are mixed, and then placed in a molding machine for molding , the forming pressure is 3×10 7 ~4×10 7 Pa; 3. The briquette fuel obtained in step 2 is dried naturally until the moisture content of the briquette fuel reaches 0.5% to 15%, that is, the biomass solidified briquette fuel is obtained.

[0011] Th...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the catalyst in step 1 is H with a mass concentration of 30% to 98%. 2 SO 4 solution or NaOH solution with a mass concentration of 20% to 35%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the catalyst in step one is 30% to 98% H with a mass concentration of 2 to 4 parts by weight. 2 SO 4 The solution is composed of 1 to 2 parts of HCl solution with a mass concentration of 20% to 36%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com