Refiner of aluminium and aluminium alloy with high efficiency and low cost and preparation method thereof

An aluminum alloy and refiner technology, which is applied in the field of high-efficiency and low-cost aluminum and aluminum alloy refiners and their preparation, can solve the problems of high process equipment requirements, poor product performance, complicated and complicated processes, etc., and achieves a simple process. , Refinement effect is good, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

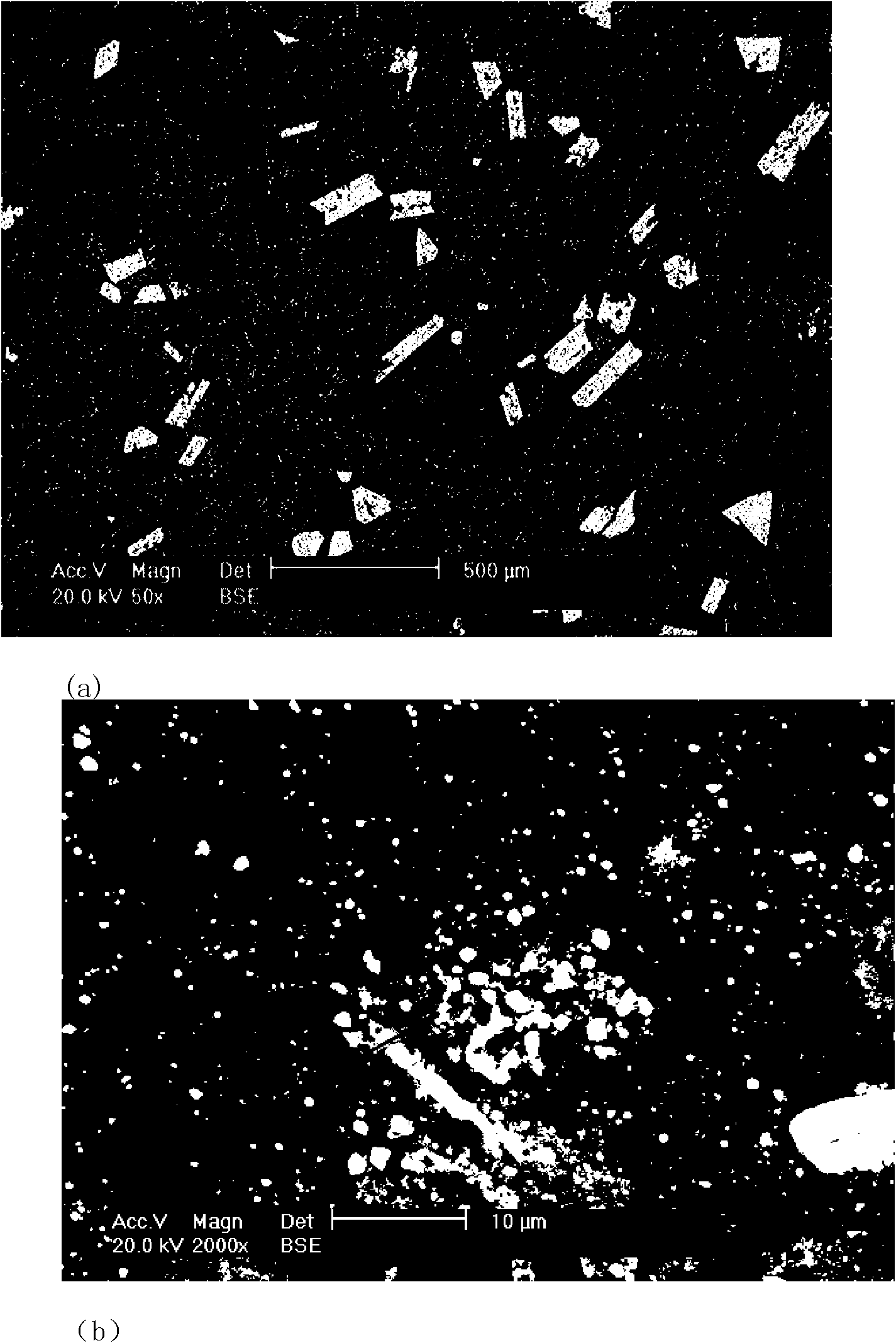

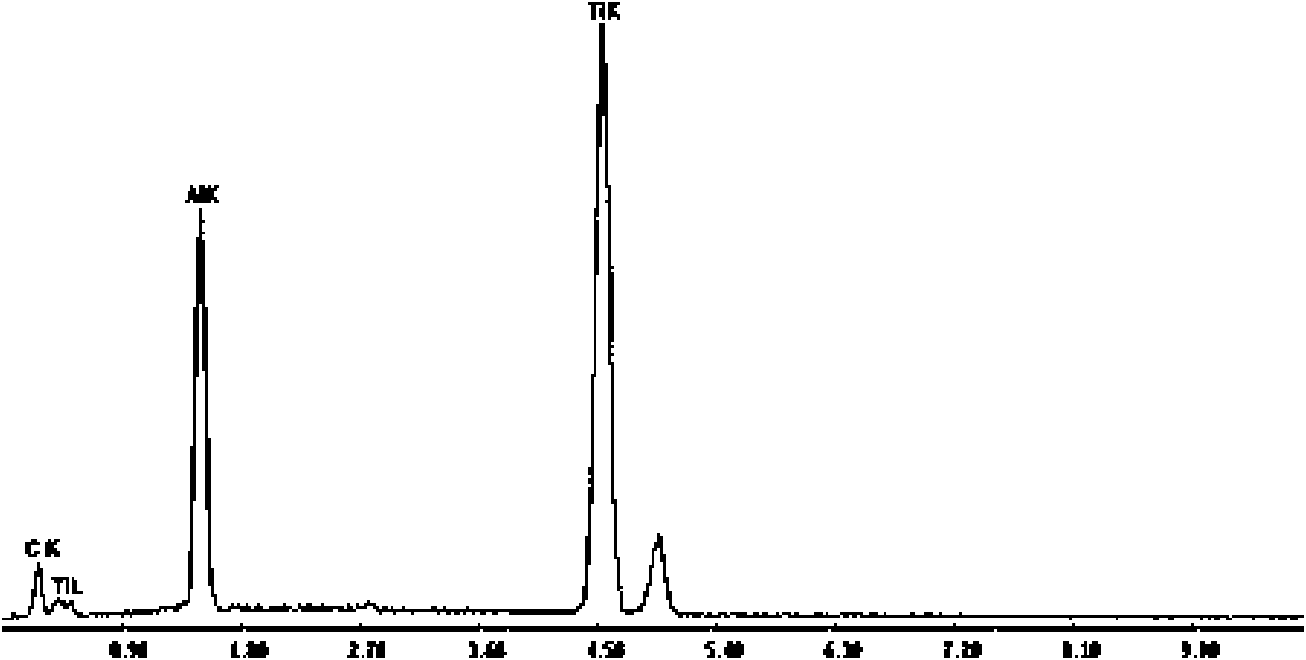

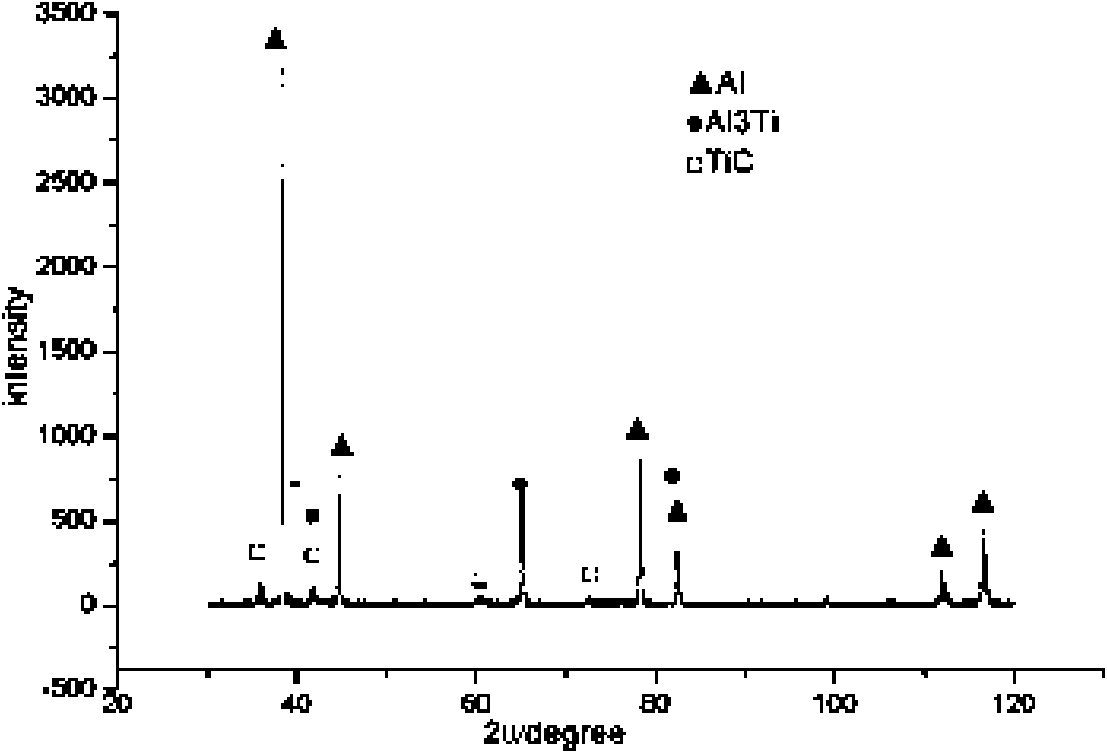

[0041] The specific embodiment of the present invention is described below in conjunction with the best example of the present invention, and cooperates accompanying drawing to fully illustrate the beneficial effects of the present invention, but the present invention is not limited thereto:

[0042] 1. Graphite powder is preheated in a crucible resistance furnace at 300-600°C for 0.52 hours, K 2 TiF 6 Preheat in a drying oven at 150°C for 0.1-2 hours.

[0043] 2. Mix graphite powder, K 2 TiF 6 Powder and rare earth compound are prepared in proportion, (the proportioning of this example: K 2 TiF 6 : graphite powder: weight percentage of rare earth compound=5:1:1) and mix evenly, then wrap with aluminum foil.

[0044] 3. Use a resistance crucible furnace or an induction furnace to melt pure aluminum, first sprinkle the flux for aluminum alloy on the bottom of the crucible, and then add aluminum ingots for melting, which can produce flux filtering effect.

[0045] 4. Super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com