Method for removing nitrate nitrogen, corresponding combination preparation, and preparation method and application thereof

A technology of nitrate nitrogen and composite preparations, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of long storage time of nano-iron, poor chemical stability, Easy to agglomerate and other problems, to achieve the effect of convenient operation, increased reaction rate constant, and low purity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The nitrate concentration in deionized water was set at 10 mg / L, and the pH was 5.5. Different formulations of composite nano-iron materials were added to carry out the nitrate degradation test. The instruments and equipment used in the test process are shown in Table 1.

[0037] Table 1 Instruments and equipment used in the test

[0038]

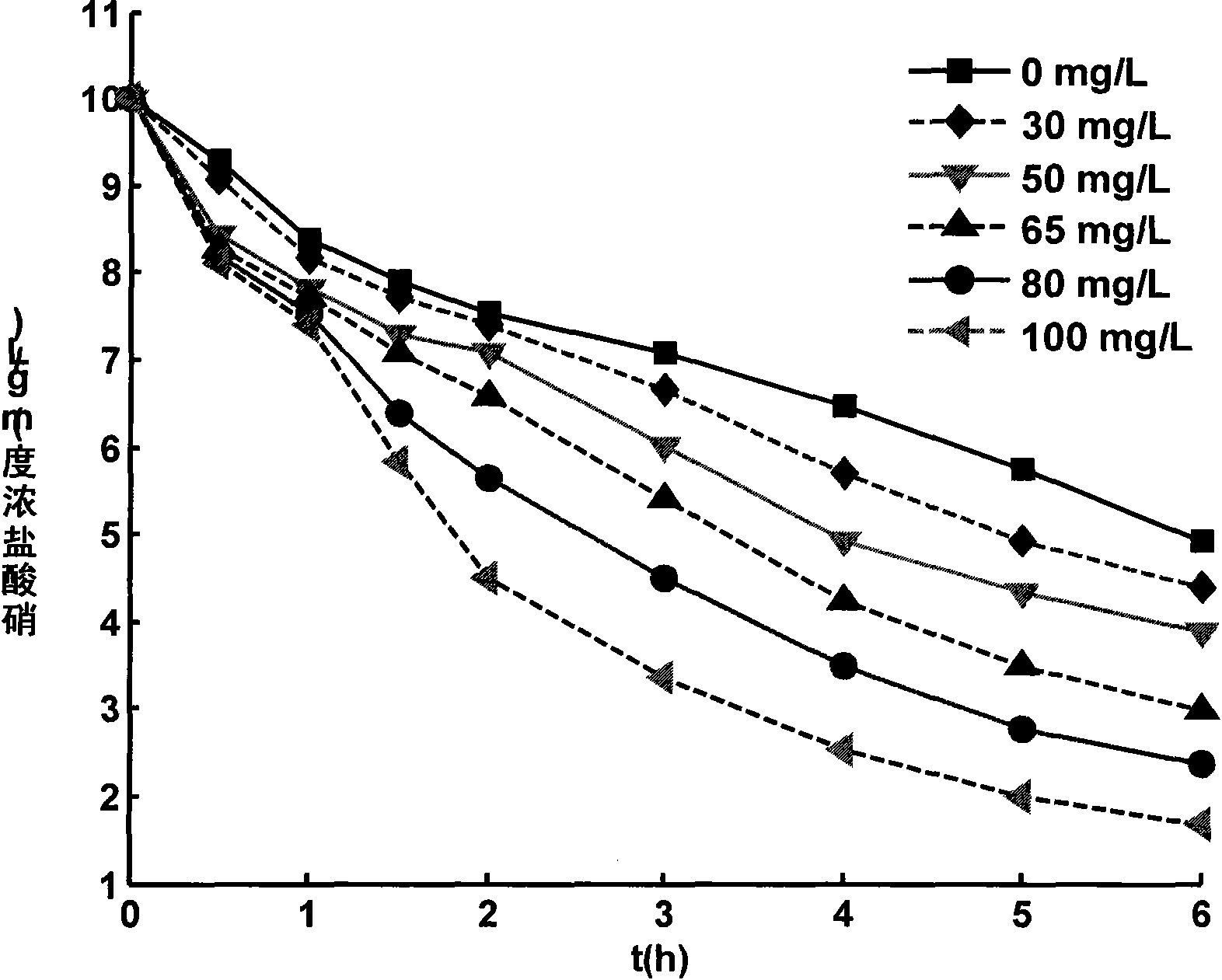

[0039] Calculated according to the concentration of substances in water, the dosage of nano-iron is 5g / L, and the dosage of aluminum sulfate is 0mg / L, 30mg / L, 50mg / L, 65mg / L, 80mg / L, 100mg / L. Below, the curve of nitric acid concentration changing with time is as follows figure 1 shown.

[0040] From figure 1 It can be clearly seen that as the content of aluminum sulfate in the composite nano-iron material increases, the removal rate and removal rate of nitrate increase significantly. Corresponding to different composite nano-iron materials, the removal rates of nitrate reached 51%, 57%, 61%, 70%, 76% and 83% after 6 hours of re...

Embodiment 2

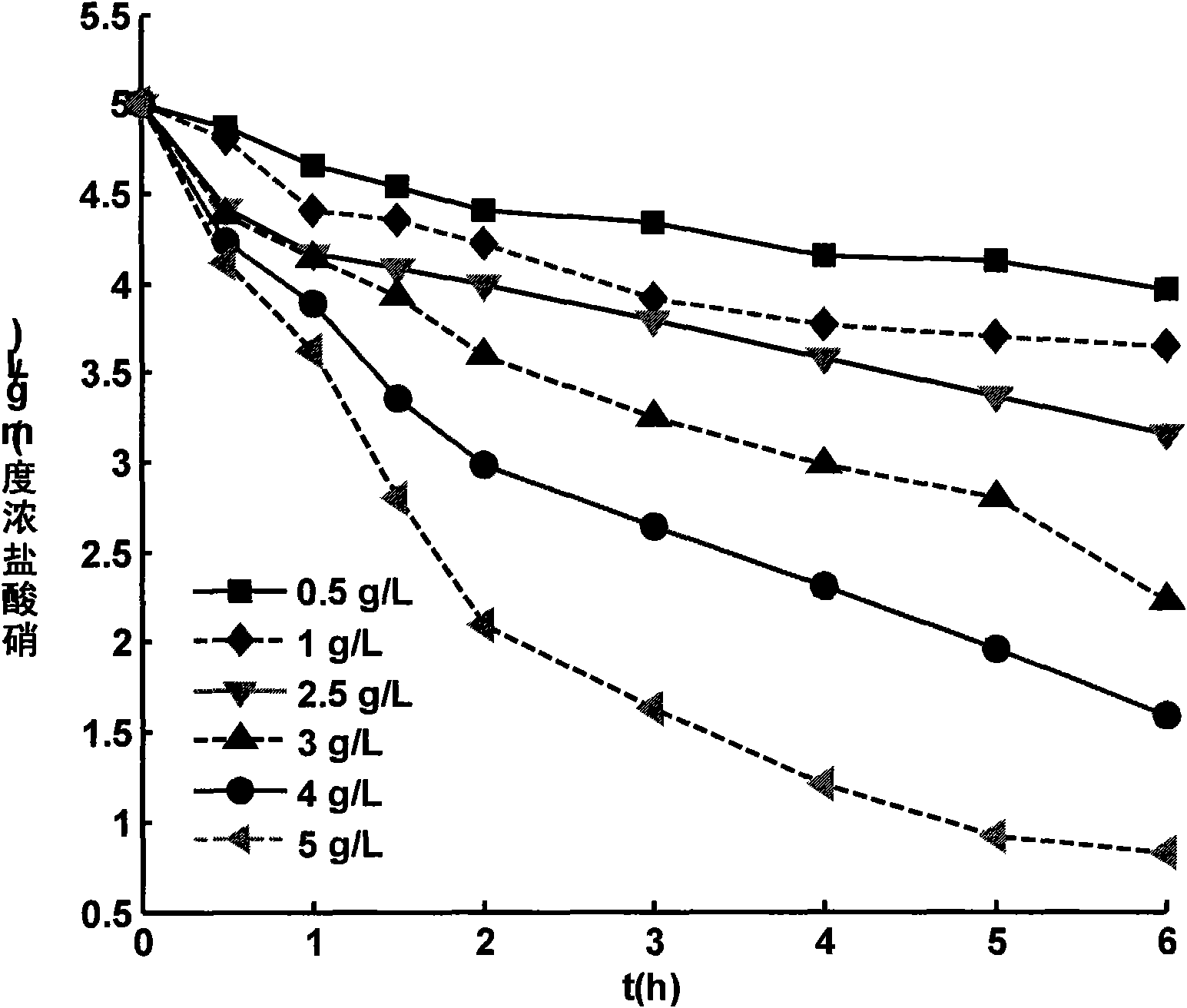

[0041] Example 2: The equipment used in the test is shown in Table 1. When the initial concentration of nitrate is 5mg / L, pH is 5.5 and under normal temperature conditions, after 6 hours of reaction, the composite nano-iron (the material ratio in the composite nano-iron is: nano-iron 98%, aluminum sulfate 2%) dosage The nitrate removal rates were 22%, 29%, 38%, 54%, 61%, and 83% when they were 0.5g / L, 1g / L, 2.5g / L, 3g / L, 4g / L, and 5g / L, respectively. %, 88%, see figure 2 . On the one hand, the increase in the dosage of composite nano-iron increases the concentration of substrate reactants and increases the driving force of the reaction; Under the joint action of the two, the rate of reduction reaction and the removal rate of nitrate are effectively improved.

Embodiment 3

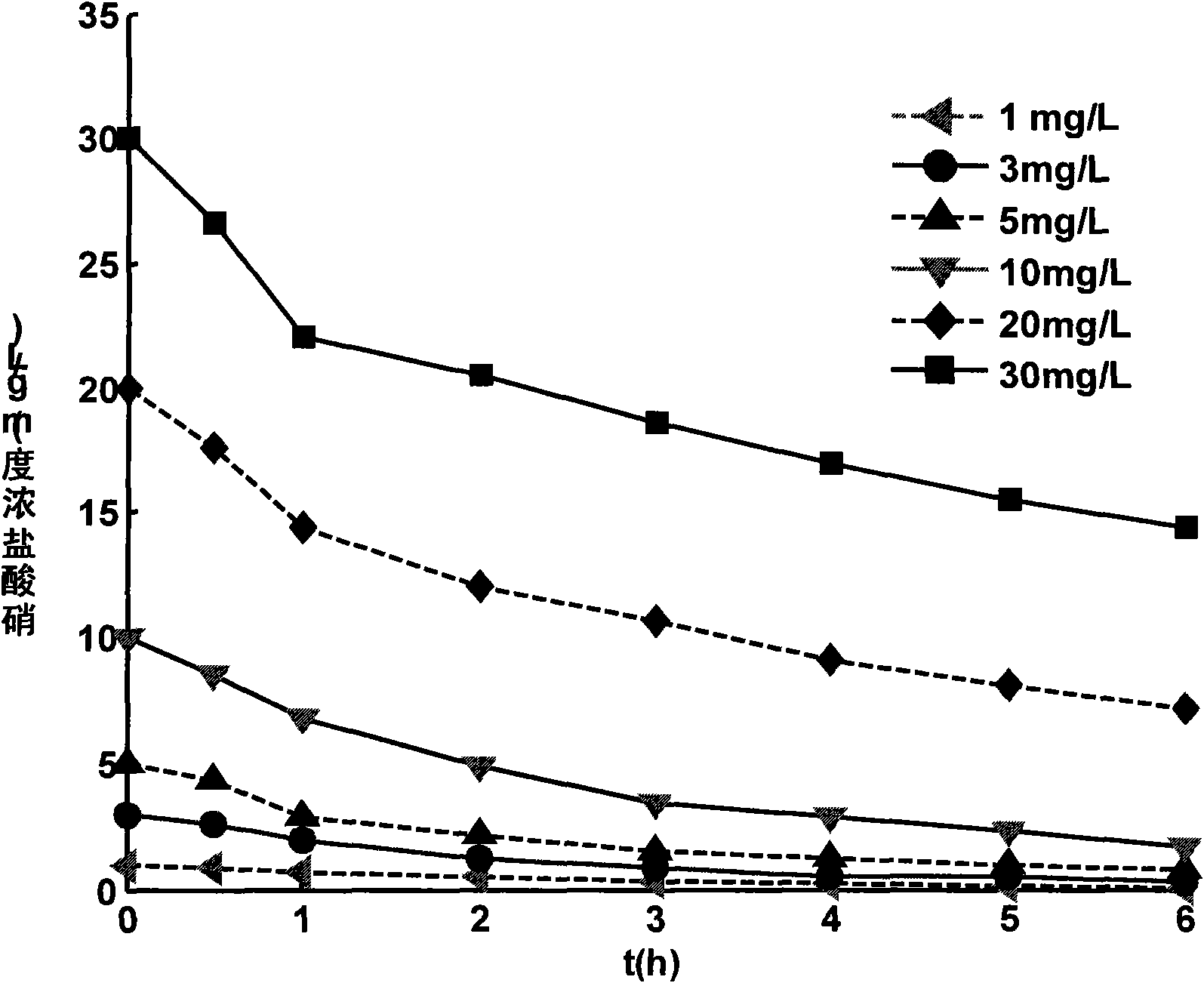

[0042] Example 3: The equipment used in the test is shown in Table 1. The dosage of composite nano-iron is 5g / L (nano-iron 98%, aluminum sulfate 2%), when the pH is 5.5, the initial concentration of nitrate nitrogen is 1, 3, 5, 10, 20, 30, 50mg / L respectively , the removal rate of nitrate after 6h at normal temperature is 92%, 89%, 85%, 83%, 68%, 53%, 44%, the results are detailed in image 3 . It can be seen that this technical method has a good removal effect for different initial concentrations of nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com