Method for preparing (Ca, Nd) TiO3 microwave dielectric ceramic by adopting sol-gel method

A technology of microwave dielectric ceramics and gel method, which is applied in the field of material science, can solve the problems of reducing additives, etc., and achieve the effect of simple equipment, stable process and ensuring homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

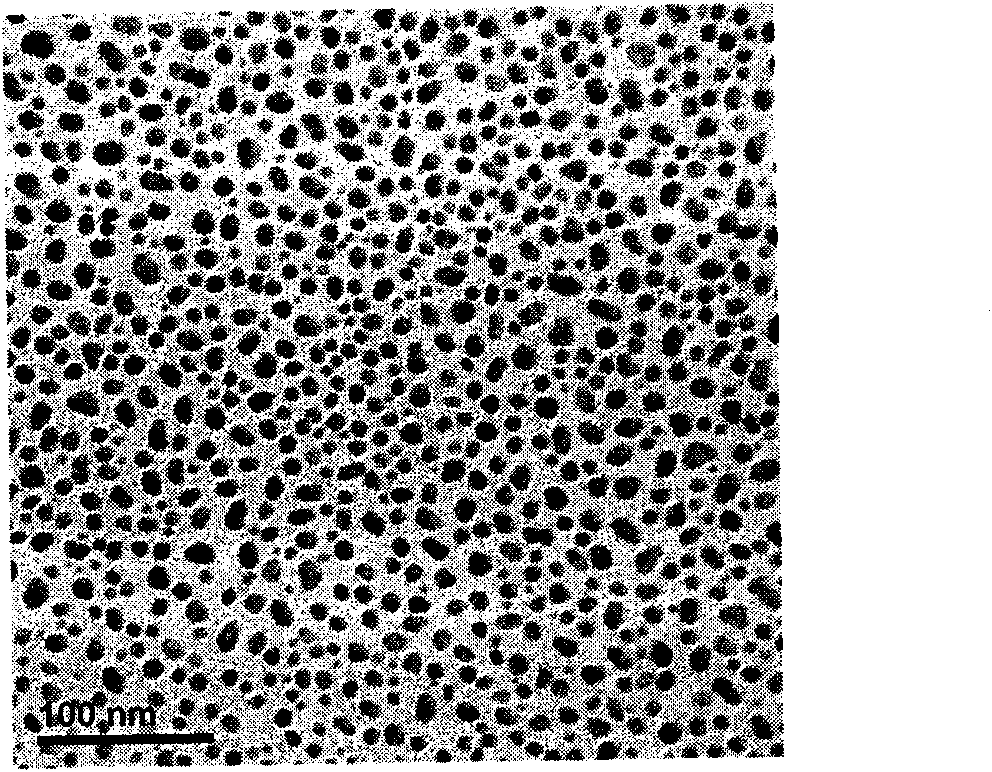

[0029] Embodiment 6, x=1.19, y=0.15, z=0.32 group point can obtain particle diameter 10~15nm, the superfine (Ca 0.61 ,Nd 0.26 )TiO 3 powder (such as figure 1 ), the powder can be sintered at 1100°C to obtain dense nanocrystals (Ca 0.61 ,Nd 0.26 )TiO 3 ceramics (such as figure 2 ), ceramics have the best microwave dielectric properties: ε r is 89.53, Q×f is 17148GHz, τ f =+239ppm / ℃, can be used in the design and production of miniature multi-layer frequency devices such as capacitors, antennas, baluns, and various filters.

[0030] Table 1.

[0031] implement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com