Method for preparing cyclopentadiene by thermaldepolymerization of dicyclopentadiene

A technology for producing cyclopentadiene and dicyclopentadiene from dicyclopentadiene, which is applied in the field of organic matter preparation to achieve the effects of increasing CPD yield, reducing energy consumption, and reducing the chance of collision and dimerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

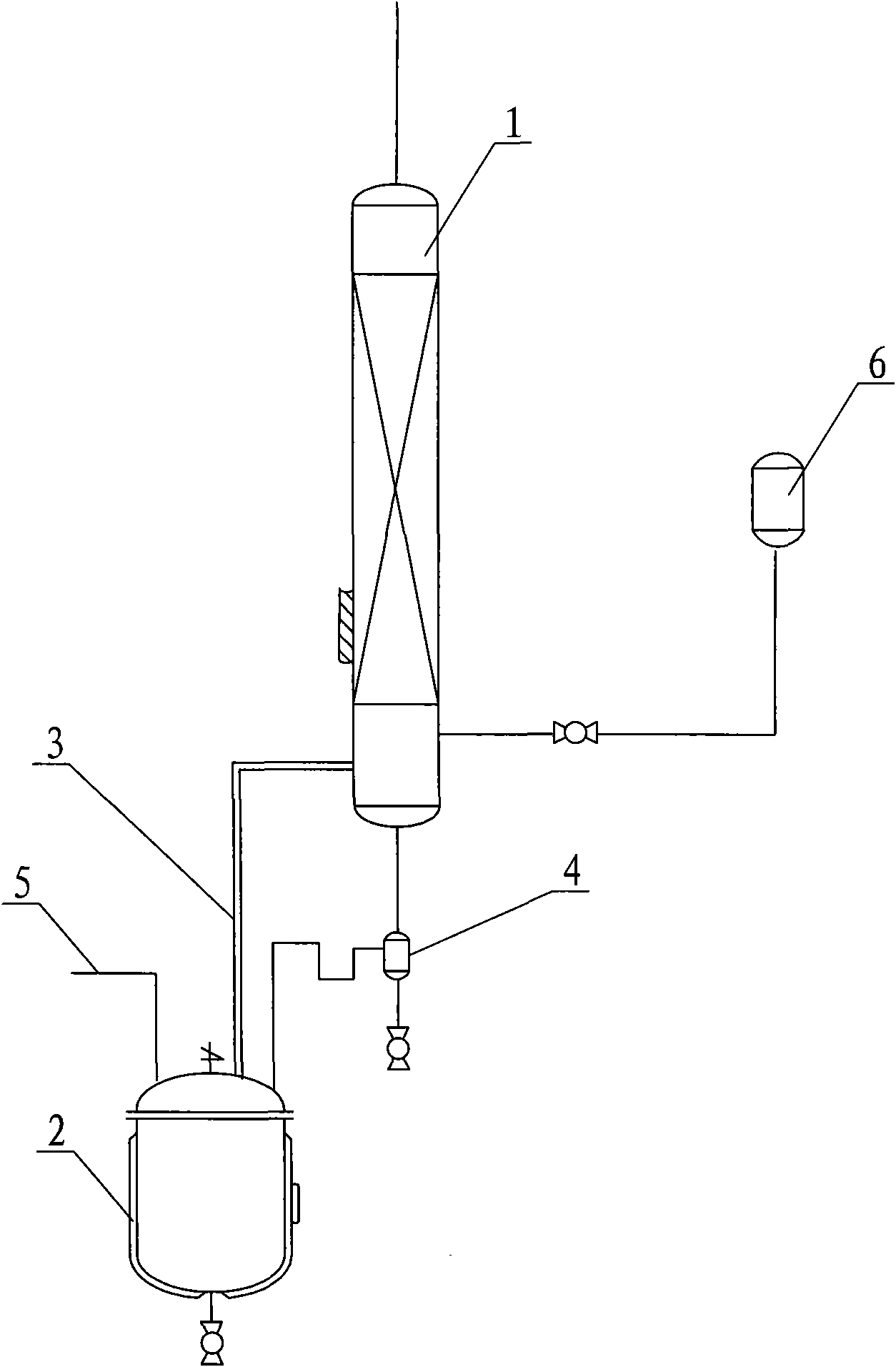

Image

Examples

Embodiment 1

[0026]160.5 g of dicyclopentadiene (content 97%) was put into a 250 ml three-neck flask equipped with a thermometer and a stirring rotor. A rectification tower is used to separate the products, the material is stainless steel, and the top of the tower is condensed with ethanol at -10°C. The flask and the bottom of the tower are connected by a volatilization tube, and a micro water pump outlet is located at the bottom of the tower. An oil-water separator is added at the bottom of the tower, and the flask is heated by an electric heating mantle. When the temperature of the kettle is about 170°C, water is sprayed to the bottom of the tower through a micro-water pump. 45°C, the flow rate of the water pump is adjusted according to the value displayed by the thermometer at the bottom of the tower. The temperature at the top of the tower is 41-42°C and remains stable. Receive the distillate, observe the stratification of the oil-water separator, and separate the water layer at regul...

Embodiment 2

[0028] 167.6 g of dicyclopentadiene (content 97%) was put into a 250 ml three-neck flask equipped with a thermometer and a stirring rotor. A rectification tower is used to separate the products, the material is stainless steel, and the top of the tower is condensed with ethanol at -10°C. The flask and the bottom of the tower are connected by a volatilization tube, and a micropump outlet is located at the bottom of the tower. The pump feed tube was inserted into the 99% cyclopentane (boiling point 46°C, temperature 17°C at this time) container. The flask is heated by an electric heating jacket. When the temperature of the kettle is about 170°C, spray cyclopentane liquid to the bottom of the tower through a micro-metering pump. The temperature displayed by the bottom thermometer is always lower than 60°C and higher than 50°C. The flow rate of the metering pump is based on the value displayed by the bottom thermometer. Adjustment. The temperature at the top of the tower is 41-4...

Embodiment 3

[0030] 169.6 g of dicyclopentadiene (content 97%) was put into a 250 ml three-neck flask equipped with a thermometer and a stirring rotor. A rectification tower is used to separate the products, the material is stainless steel, and the top of the tower is condensed with ethanol at -10°C. The flask and the bottom of the tower are connected by a volatilization tube, and a micropump outlet is located at the bottom of the tower. The feed pipe of the pump was inserted into the container of chloroform (boiling point 61° C. under normal pressure). The flask is heated by an electric heating jacket. When the temperature of the kettle is about 170°C, the chloroform liquid is sprayed to the bottom of the tower through a micrometering pump. The temperature displayed by the bottom thermometer is always lower than 60°C and higher than 45°C. The flow rate of the metering pump is based on the value displayed by the bottom thermometer. Adjustment. The temperature at the top of the tower is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com