Method for synthesizing bisphenol A ethoxy compound

A technology for ethoxylates and synthesis methods, applied in chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, chemical/physical processes, etc., can solve the problem of increased production costs, recovery of solvent consumption and energy consumption Increase and other problems to achieve the effect of simple and easy steps and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of bisphenol A polyoxyethylene ether with a degree of polymerization of 4, BPA-4EO.

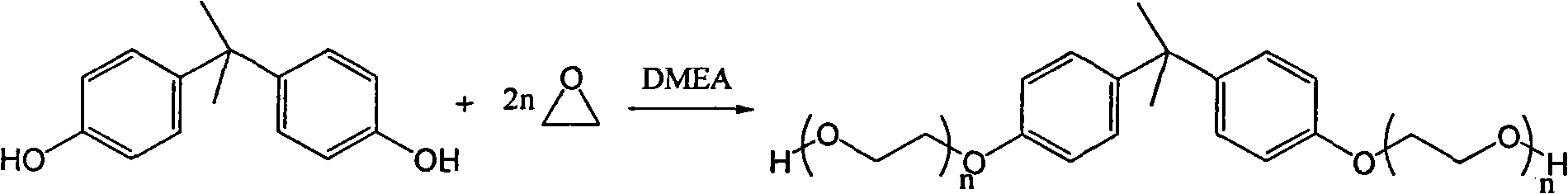

[0020] The reaction formula is as follows:

[0021]

[0022] This example is a typical bisphenol A polyoxyethylene ether, named BPA-4EO, this product is produced after acrylated bisphenol A polyoxyethylene ether diacrylate, the English abbreviation is 4EOBPDA, and the ratio of BPA-4EO is the number of moles BPA: EO = 1: 4, the hydroxyl value requirement is 280±10mgKOH / g.

[0023] First add 1000 grams of bisphenol A and 2 grams of dimethylaminoethanol into the reaction kettle, under the protection of nitrogen, then set the frequency modulation motor speed to 50 rpm, heat up with steam to 120 ° C to add EO, and then put in 190 grams After EO, gradually increase the stirring speed to 180 rpm. Until the completion of adding EO to 763 grams, ensure that the temperature does not exceed 120°C; the pressure does not exceed 0.35Mpa, and react for 4.5 hours to obtai...

Embodiment 2

[0024] Example 2: Preparation of bisphenol A polyoxyethylene ether with a degree of polymerization of 6, BPA-6EO.

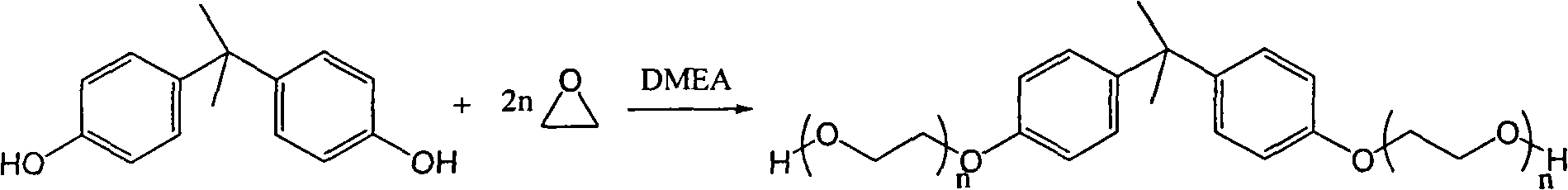

[0025] The reaction formula is as follows:

[0026]

[0027] This example is a typical bisphenol A polyoxyethylene ether, named BPA-6EO. This product is produced after acrylated bisphenol A polyoxyethylene ether diacrylate, the English abbreviation is 6EOBPDA, and the ratio of BPA-6EO is the number of moles BPA:EO=1:6, the hydroxyl value requirement is 230±10mgKOH / g.

[0028] First add 800 grams of bisphenol A and 2.6 grams of dimethylaminoethanol into the reaction kettle, under the protection of nitrogen, then set the frequency modulation motor speed to 50 rpm, heat the temperature with steam to 120 ° C to add EO, and then put in 154 grams After EO, gradually increase the stirring speed to 180 rpm. Until the completion of adding EO to 926 grams, ensure that the temperature does not exceed 120°C; the pressure does not exceed 0.35Mpa, and react for 6 hours ...

Embodiment 3

[0029] Example 3: Preparation of bisphenol A polyoxyethylene ether with a degree of polymerization of 10, BPA-10EO.

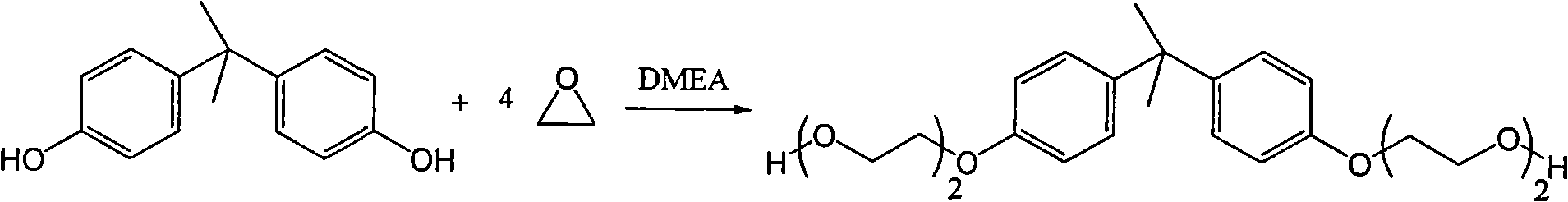

[0030] The reaction formula is as follows:

[0031]

[0032] This example is a product of 10 moles of bisphenol A polyoxyethylene ether, named BPA-10EO. This product is acrylated to produce bisphenol A polyoxyethylene ether diacrylate, the English abbreviation is 10EOBPDA, and the proportion is the number of moles of BPA: EO=1:10, the hydroxyl value requires 170±10mgKOH / g.

[0033] First add 600 grams of bisphenol A and 5.3 grams of dimethylaminoethanol into the reaction kettle, under the protection of nitrogen, then set the frequency modulation motor speed to 50 rpm, use steam to heat up the temperature to 115°C to add EO, and then put in 110 grams After EO, gradually increase the stirring speed to 180 rpm. Until the completion of adding EO to 1158 grams, ensure that the temperature does not exceed 120°C; the pressure does not exceed 0.35Mpa, and react ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com