Method for preparing bismuth sulfide nanorod crystal material

A technology of crystal materials and nanorods, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., to achieve the effect of clean products, simple operation procedures, and few controllable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

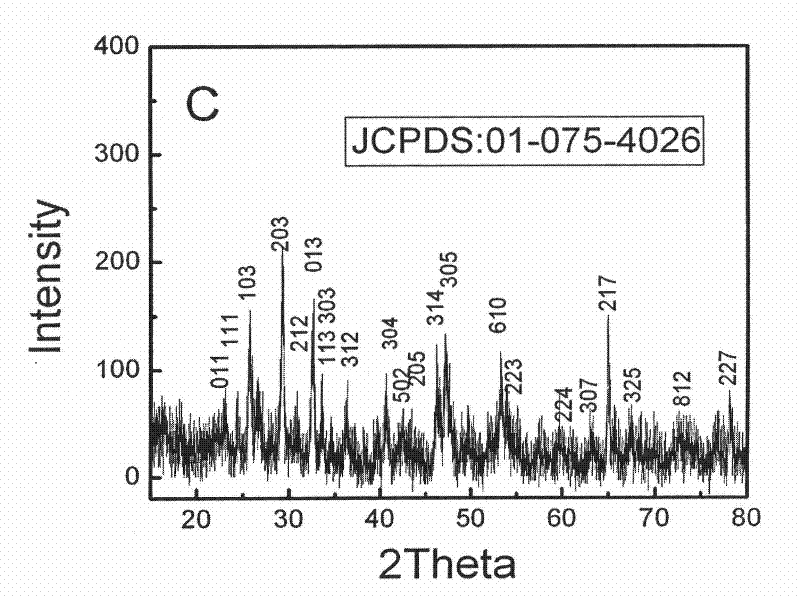

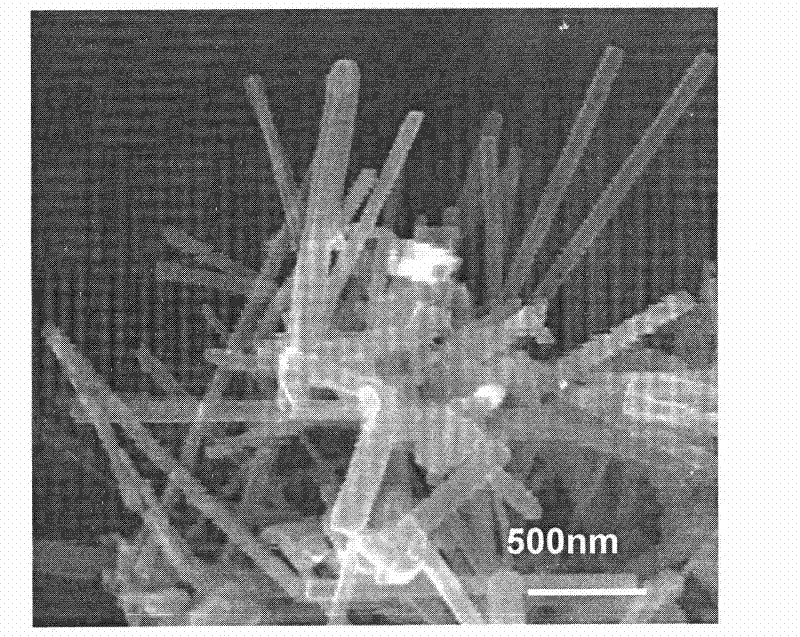

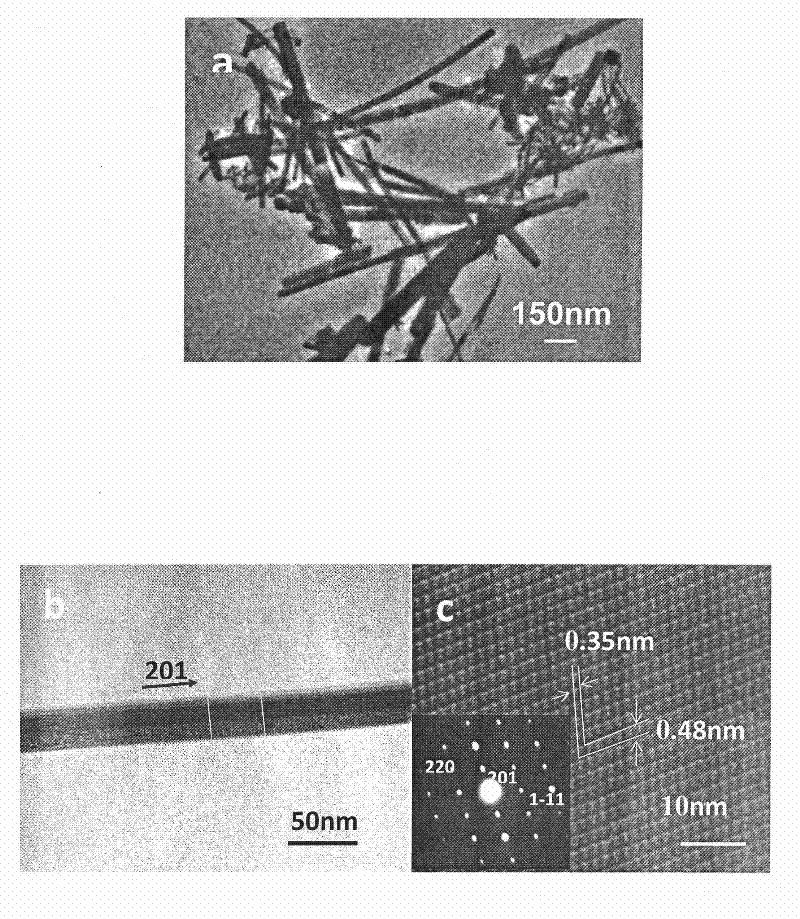

[0026] Concrete synthetic method of bismuth sulfide nanorod crystal material

[0027] The raw material for the synthesis of bismuth sulfide nanorod crystal material is LiNO 3 、KNO 3 , bismuth nitrate (Bi(NO 3 )3·5H 2 O), sodium sulfide (Na 2 S·9H 2 O), the step-by-step reaction that takes place is as follows:

[0028] Bi(NO 3 )3·5H 2 O → Bi 3+ +3NO 3- +5H 2 O,

[0029] Na 2 S·9H 2 O→2Na + +S 2- +9H 2 O,

[0030] 2 Bi 3+ +3S 2- → Bi 2 S 3 .

[0031] The specific operation steps are as follows:

[0032] Step 1, by weight percentage LiNO 3 = 42% and KNO 3 =58% weighed and mixed as a reaction solvent.

[0033] Step 2, press bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) percent by weight=57.98%, sodium sulfide (Na 2 S·9H 2 O) % by weight = 41.02% weighed as reactant. The weight percent of reactants to reactants+reaction solvent was 0.9%.

[0034] Step 3, put the reaction raw materials of the above step 2 and the reaction solvent in the above step 1 into a po...

Embodiment 2

[0039] Concrete synthetic method of bismuth sulfide nanorod crystal material

[0040] The raw material for the synthesis of bismuth sulfide nanorod crystal material is LiNO 3 、KNO 3 , bismuth nitrate (Bi(NO 3 )3·5H 2 O), sodium sulfide (Na 2 S·9H 2 O), the step-by-step reaction that takes place is as follows:

[0041] Bi(NO 3 )3·5H 2 O → Bi 3+ +3NO 3- +5H 2 O,

[0042] Na 2 S·9H 2 O→2Na + +S 2- +9H 2 O,

[0043] 2 Bi 3+ +3S 2- → Bi 2 S 3 .

[0044] The specific operation steps are as follows:

[0045] Step 1, by weight percentage LiNO 3 = 10% and KNO 3 =90% Weighed and mixed as a reaction solvent.

[0046] Step 2, press bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) percent by weight=10%, sodium sulfide (Na 2 S·9H 2 O) or weight percent of sulfur = 90% is weighed as reactant. The weight percentage of reactant to reactant+reaction solvent is 0.5%.

[0047] Step 3, put the reaction raw materials in the above step 2 and the reaction solvent in the above ste...

Embodiment 3

[0051] Concrete synthetic method of bismuth sulfide nanorod crystal material

[0052] The raw material for the synthesis of bismuth sulfide nanorod crystal material is LiNO 3 、KNO 3 , bismuth nitrate (Bi(NO 3 )3·5H 2 O), sodium sulfide (Na 2 S·9H 2 O), the step-by-step reaction that takes place is as follows:

[0053] Bi(NO 3 )3·5H 2 O → Bi 3+ +3NO 3- +5H 2 O,

[0054] Na 2 S·9H 2 O→2Na + +S 2- +9H 2 O,

[0055] 2 Bi 3+ +3S 2- → Bi 2 S 3 .

[0056] The specific operation steps are as follows:

[0057] Step 1, by weight percentage LiNO 3 = 90% and KNO 3 = 10% weighed and mixed as a reaction solvent.

[0058] Step 2, press bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) weight percent=90%, sodium sulfide (Na 2 S·9H 2 O) or weight percent of sulfur = 10% weighed as reactant. The weight percentage of reactant to reactant+reaction solvent is 50%.

[0059] Step 3, put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com