Multi-beam long-rail interferometer for detecting grazing tubular off-axis aspheric mirror

An off-axis aspheric, multi-beam technology, applied in the field of optical detection, can solve the problems of difficult positioning, affecting measurement accuracy, insufficient sharpness of interference fringes, etc., and achieves the effects of easy fabrication, accurate measurement results, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

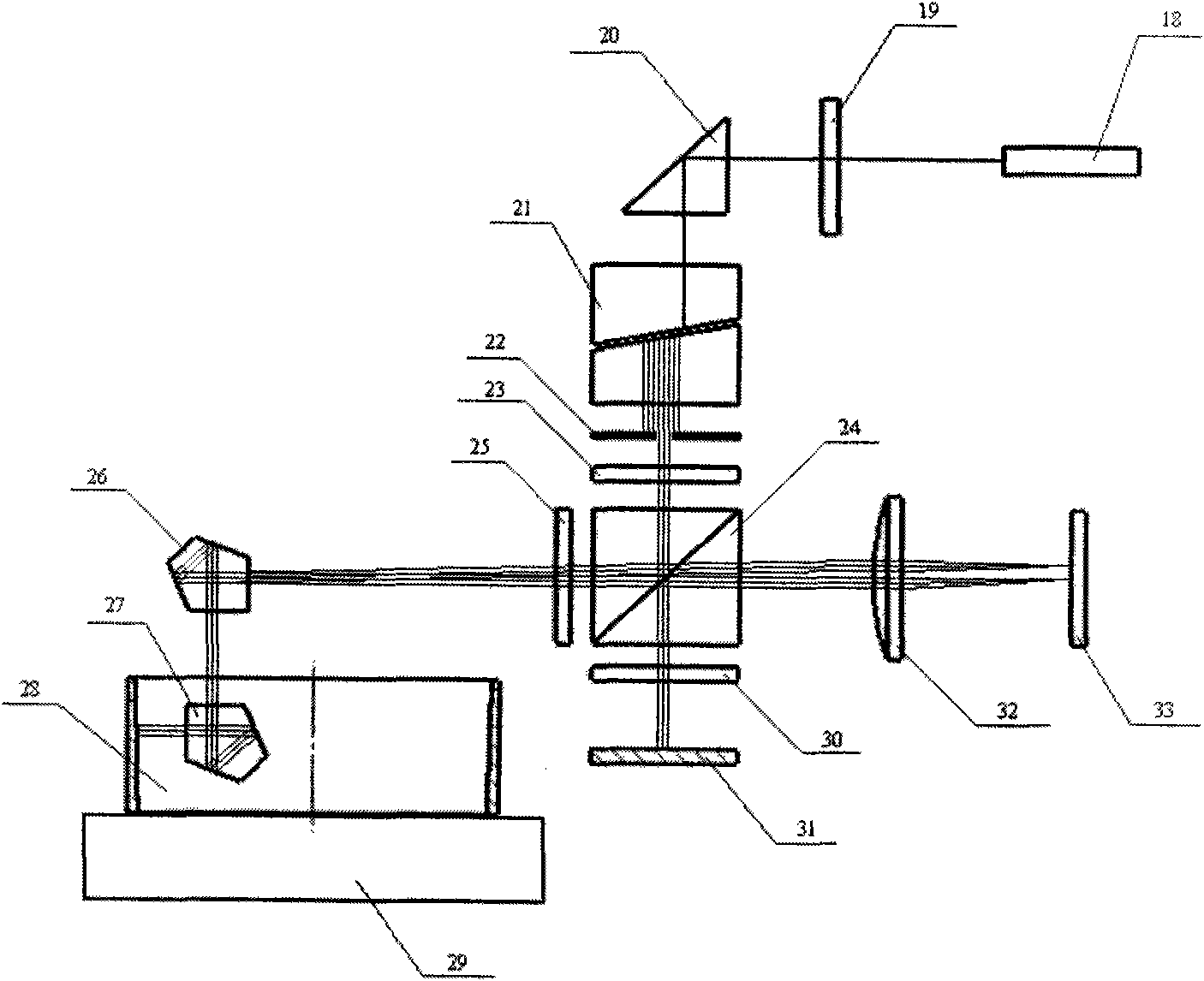

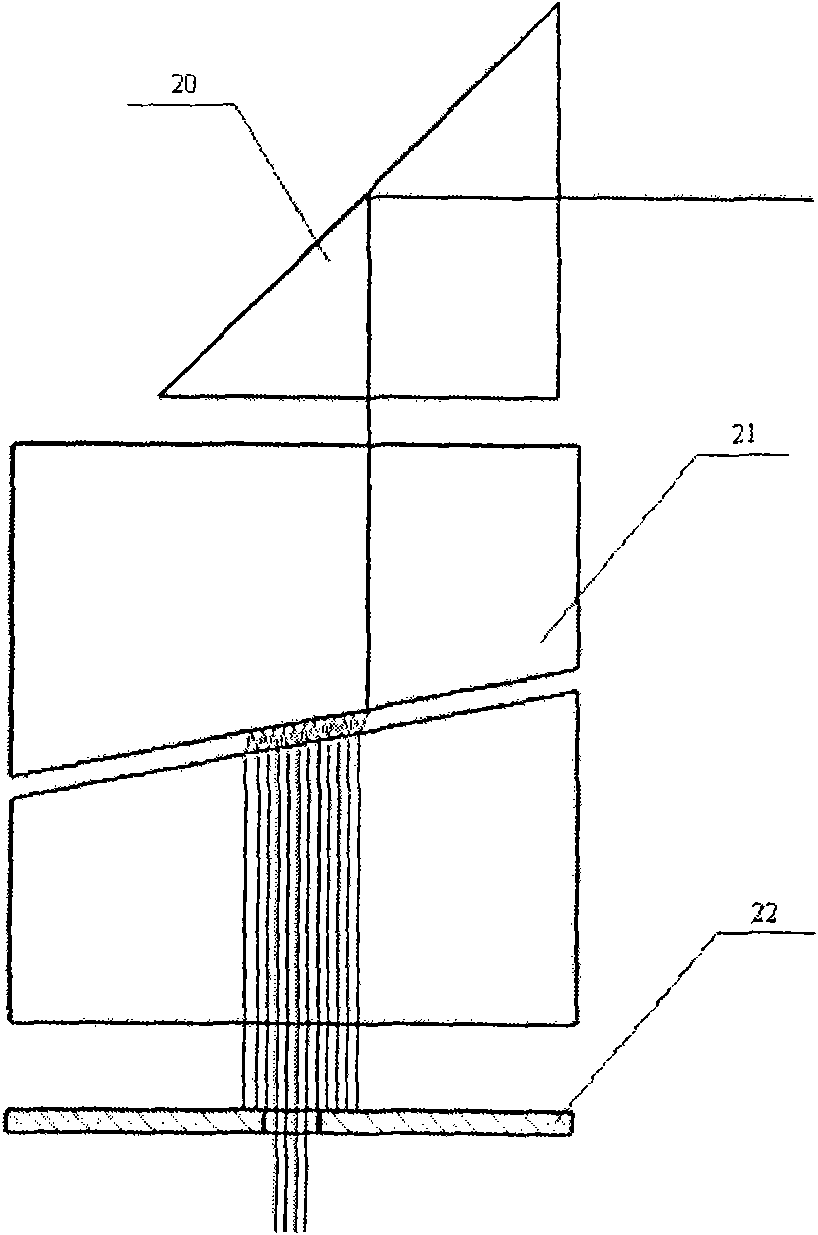

[0014] The invention according to figure 2 with image 3 The structure shown is implemented. Wherein the laser light source 18 adopts a helium-neon laser, which requires stable output power. The polarizer 19 is placed in front of the laser light source 18 to change the laser beam emitted by the laser light source 18 into linearly polarized light, and the diameter is required to be larger than the cross section of the laser beam. The rectangular prism 20 is made of ordinary K9 optical glass, the rectangular surface is used as the incident surface and placed perpendicular to the optical axis, and the inclined surface is used as the reflecting surface at 45 degrees to the optical axis to deflect the laser beam by 90 degrees. The multi-beam beam splitter 21 is also made of ordinary Made of K9 optical glass, divided into upper and lower parts, such as image 3 The two parts shown have the same structure and the cross-section is trapezoidal. The angle between the trapezoidal hypo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com