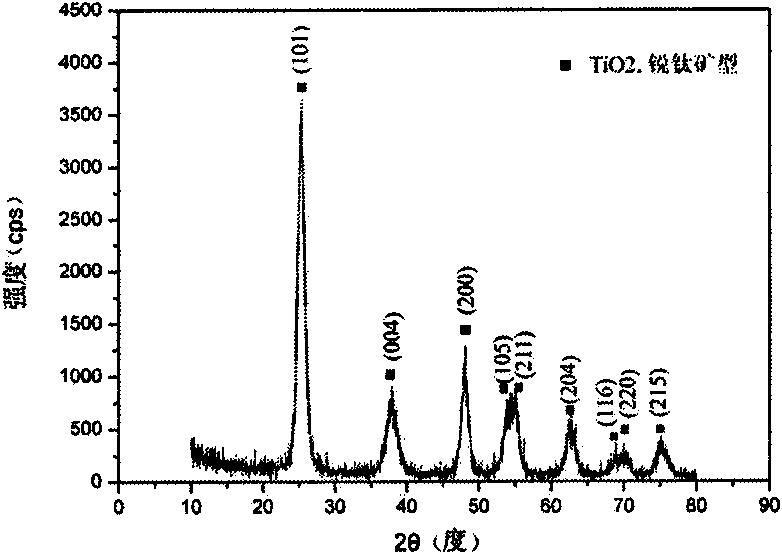

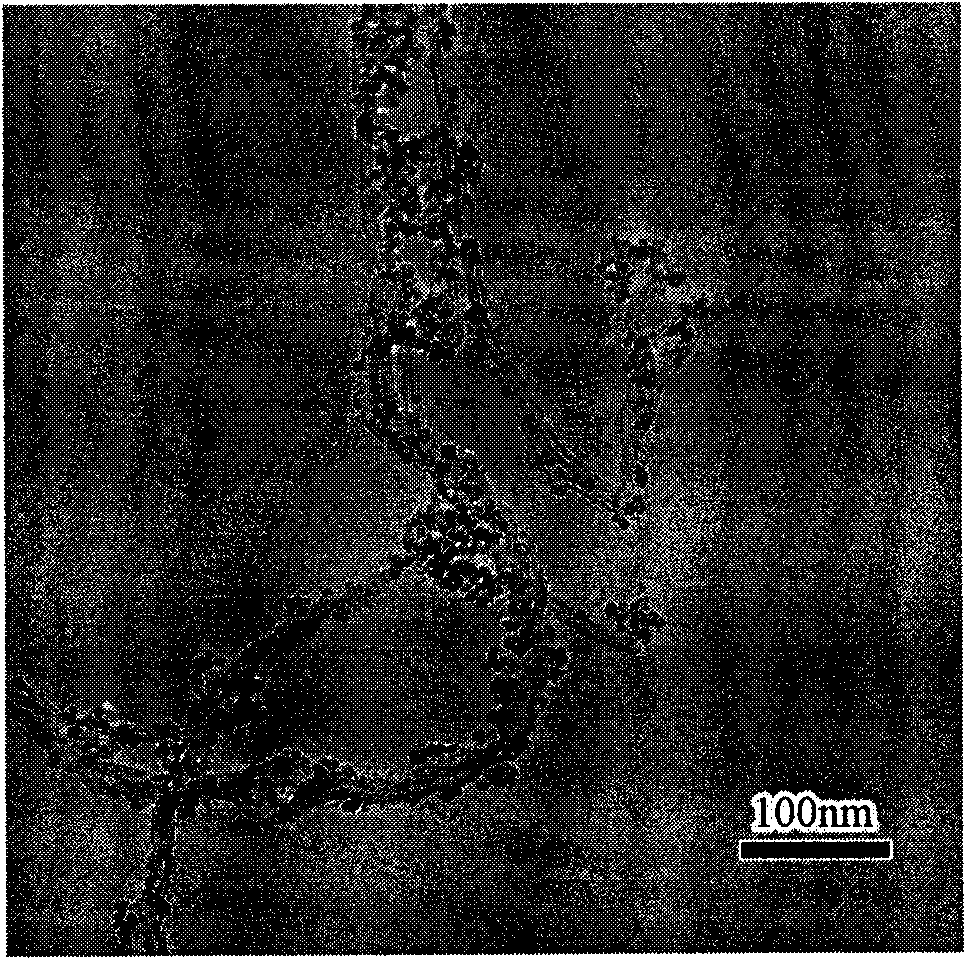

Catalyst using TiO2-coated carbon nano tube composite material as carrier and preparation method thereof

A technology of composite materials and carbon nanotubes, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as flue gas and catalyst mass transfer process bottlenecks, and achieve easy industrial production and process Simple, high-yield results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 3. 4g of carbon nanotubes were ultrasonically dispersed in 700mL of absolute ethanol, and ultrasonically oscillated for 30 minutes to prepare liquid A; 170g of tetrabutyl titanate was dissolved in 700ml of absolute ethanol, and 30mL of The mass concentration is 10% ammonium metavanadate (NH 4 VO 3 ) of the oxalic acid solution, ultrasonic vibration for 30 minutes to obtain liquid B; under the condition of ultrasonic oscillation, slowly add liquid A to liquid B, and after ultrasonic oscillation for 30 minutes, place the mixed solution in a 2000mL sealed reaction kettle, and seal the reaction kettle. Insulate at 230°C for 2 hours; after cooling to room temperature, filter, wash the product with deionized water until neutral, and vacuum dry at 60°C to obtain a black powder catalyst. active ingredient V 2 o 5 The mass content in the catalyst is 5%.

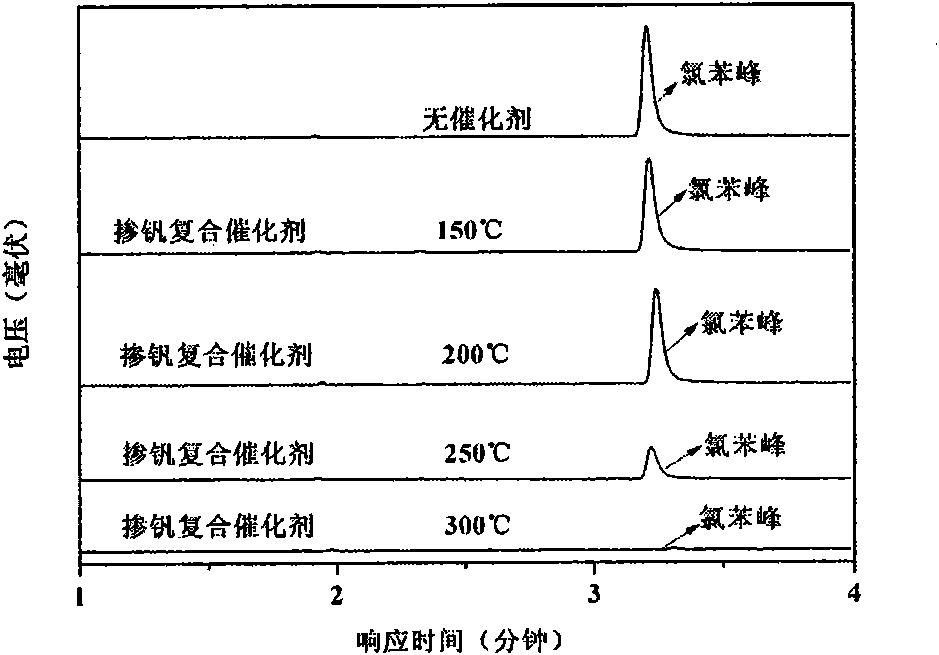

[0028] The sample was reacted with simulated industrial waste gas components in a fixed-bed reactor, and its catalytic ...

Embodiment 2

[0030] 3.4g of carbon nanotubes were ultrasonically dispersed in 700mL of absolute ethanol, and ultrasonically oscillated for 30 minutes to prepare liquid A; 170g of tetrabutyl titanate was dissolved in 700ml of absolute ethanol, and 5.7 The mL mass concentration is 10% ammonium metavanadate (NH 4 VO 3 ) of the oxalic acid solution, ultrasonic vibration for 30 minutes to obtain liquid B; under the condition of ultrasonic oscillation, slowly add liquid A to liquid B, and after ultrasonic oscillation for 30 minutes, place the mixed solution in a 2000mL sealed reaction kettle, and seal the reaction kettle. Insulate at 230°C for 2 hours; after cooling to room temperature, filter, wash the product with deionized water until neutral, and vacuum-dry at 60°C to obtain a black powder catalyst. active ingredient V 2 o 5 The mass content in the catalyst is 1%.

Embodiment 3

[0032] 3. 4g of carbon nanotubes were ultrasonically dispersed in 700mL of absolute ethanol, and ultrasonically oscillated for 30 minutes to prepare liquid A; 170g of tetrabutyl titanate was dissolved in 700ml of absolute ethanol, and 100mL of The mass concentration is 14% ammonium metavanadate (NH 4 VO 3 ) of the oxalic acid solution, ultrasonic vibration for 30 minutes to obtain liquid B; under the condition of ultrasonic oscillation, slowly add liquid A to liquid B, and after ultrasonic oscillation for 30 minutes, place the mixed solution in a 2000mL sealed reaction kettle, and seal the reaction kettle. Insulate at 230°C for 2 hours; after cooling to room temperature, filter, wash the product with deionized water until neutral, and vacuum-dry at 60°C to obtain a black powder catalyst. active ingredient V 2 o 5 The mass content in the catalyst is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com